When working with marine propulsion systems, having a clear understanding of the motor’s internal structure is crucial for effective maintenance and repair. Each system is made up of numerous components that contribute to its overall performance. Identifying and understanding these elements allows for smoother operations and easier troubleshooting when issues arise.

Proper maintenance of your system can extend its lifespan and improve efficiency. With a thorough breakdown of individual components, you can ensure that each part is in working order. Whether you’re performing routine checks or addressing more serious malfunctions, knowledge of how everything fits together is essential.

Identifying key components and their functions helps you stay ahead of potential problems, saving both time and money. A detailed overview of each part’s role ensures that you’re prepared to handle any maintenance task confidently. This guide will help you familiarize yourself with the system’s essential elements and provide practical insights into keeping your motor in top condition.

Understanding Motor Components

Each boating propulsion system is composed of several critical elements that work together to ensure smooth operation. Familiarity with these key parts is essential for efficient maintenance and troubleshooting. Whether you’re new to boat motors or an experienced user, understanding how each part contributes to performance is crucial for optimal care and longevity.

Main Components of a Marine Motor

- Propulsion Unit: Responsible for driving the boat through water, this component generates the thrust needed for movement.

- Powerhead: The engine’s powerhouse, containing the motor and key mechanisms that generate the necessary force.

- Steering Mechanism: Allows for maneuverability, making it possible to change direction while operating the vessel.

- Electrical System: Powers the motor and other critical elements, ensuring functionality and control.

- Mounting Hardware: Secures the motor to the boat, ensuring stability during operation.

Importance of Proper Understanding

Knowing the specific role and function of each component helps you diagnose issues and perform effective repairs. It allows for quick identification of any malfunctioning parts, saving time and reducing repair costs. Additionally, regular inspections of these elements will keep the motor running smoothly for years to come. Understanding the structure ensures that you’re well-equipped to maintain or replace components as necessary.

How to Identify Key Components

Identifying the various components of a marine motor is essential for both routine maintenance and effective troubleshooting. Knowing which parts perform specific functions allows you to quickly diagnose and address any issues that may arise. This section will guide you through the process of recognizing the critical elements that contribute to the overall functionality of your motor.

Step-by-Step Identification Process

- Inspect the Motor Housing: Begin by examining the outer casing of the motor. This provides access to most of the internal parts and is a good starting point for identification.

- Check the Powerhead: Look for the main engine unit. It’s often the largest component and houses the essential mechanics responsible for generating power.

- Identify the Propeller and Shaft: These components are responsible for propelling the boat forward. Ensure that the shaft is properly aligned and the propeller is undamaged.

- Locate the Steering Mechanism: This includes the control system that adjusts the direction of the motor, typically found at the back of the unit.

- Examine Electrical Connections: Check the wires and battery connections to ensure there are no loose or corroded components affecting power delivery.

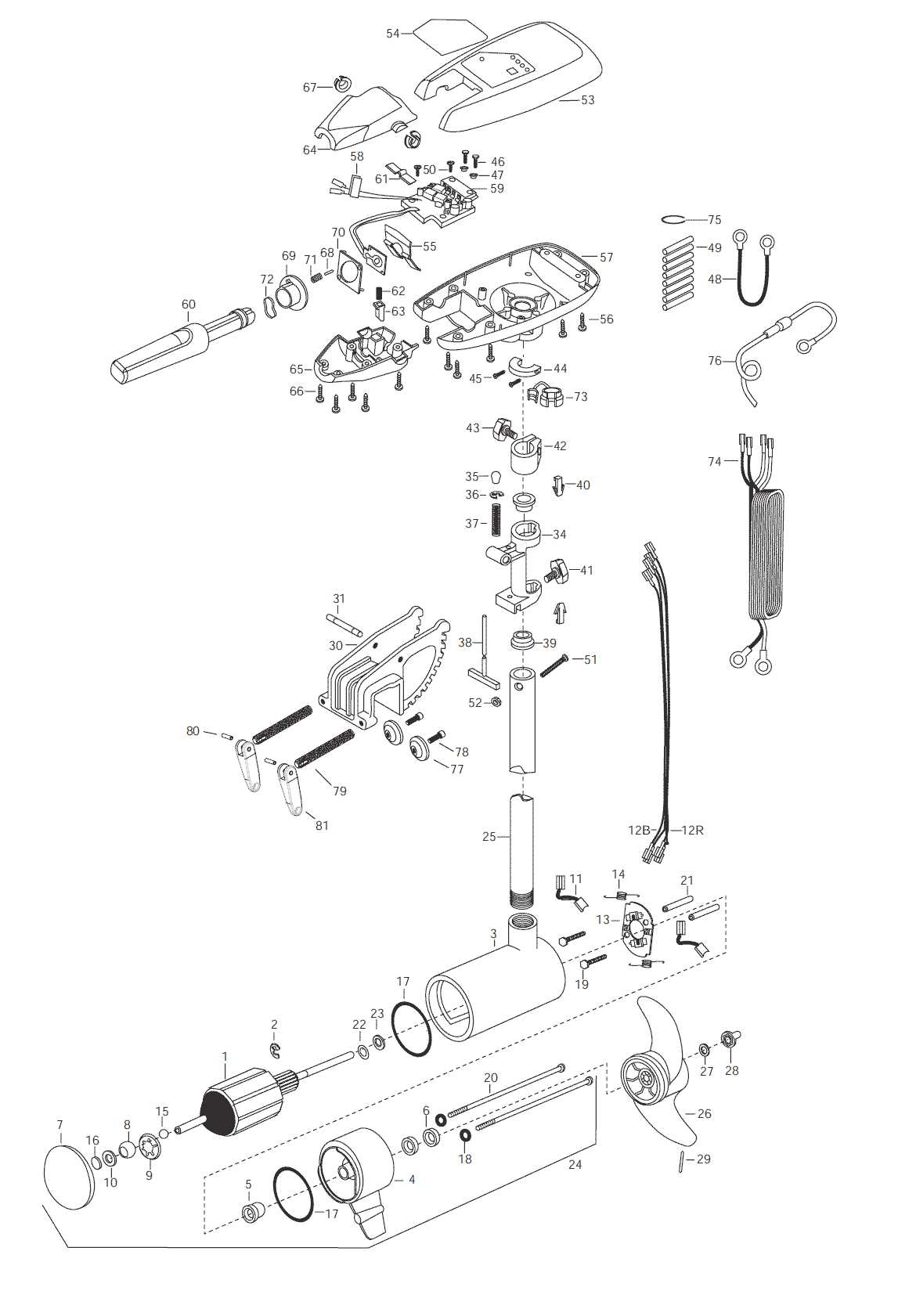

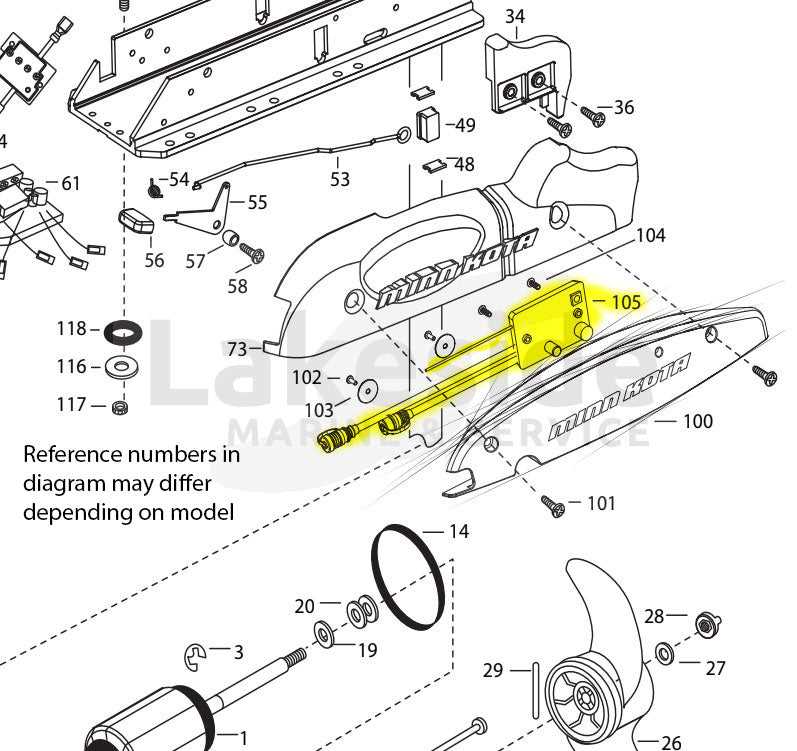

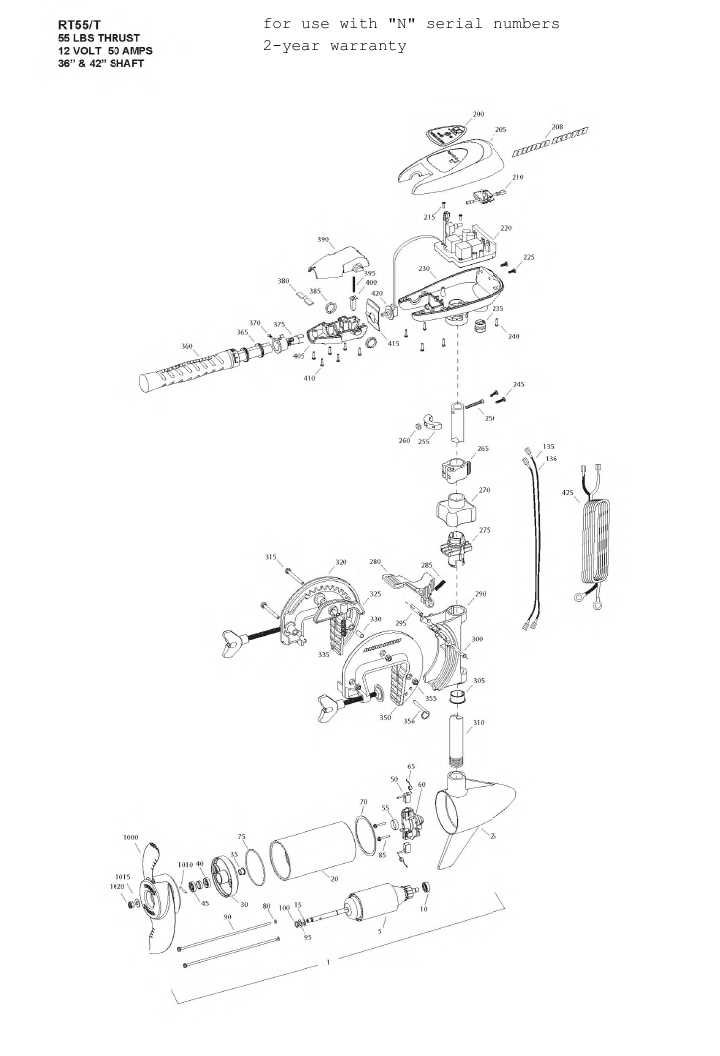

Using Visual Aids for Accuracy

When identifying the parts, using visual references like detailed diagrams or repair manuals can be incredibly helpful. These resources offer clear depictions of the system’s internal components and their arrangement, making it easier to pinpoint each part. Keep these guides on hand when performing inspections or repairs to ensure that all components are properly identified and addressed.

Repairing Marine Motors

When your boat’s propulsion system encounters a malfunction, timely repairs are crucial to prevent further damage and ensure reliable performance. Understanding the mechanics of the motor helps to identify potential issues early, allowing for more efficient fixes. Whether dealing with minor issues or more serious breakdowns, the key to effective repairs is a structured approach to diagnosing and addressing problems.

Begin by performing a thorough inspection of the motor, checking for common issues such as electrical failures, damaged propellers, or misalignment in the mechanical parts. Once the problem is identified, you can proceed with the necessary repairs or replacements. If the issue is electrical, ensure that all connections are secure and free from corrosion. For mechanical failures, it may be necessary to replace damaged components such as the drive shaft or seals.

Using the right tools is essential for carrying out repairs safely and efficiently. Make sure you have access to the proper equipment, including wrenches, screwdrivers, and multimeters for electrical checks. Additionally, always follow the manufacturer’s recommendations and guidelines to ensure you’re repairing the motor correctly and avoiding unnecessary damage.

Step-by-Step Guide for Troubleshooting

When facing issues with your motor, a systematic approach to troubleshooting is essential. By breaking down the process into manageable steps, you can efficiently identify and resolve problems. This guide will help you understand how to approach motor issues, ensuring that you cover all the necessary aspects for effective repairs.

Start with a Visual Inspection: Begin by checking for any visible signs of damage or wear. Look for loose or disconnected wires, corroded connections, or broken components. This initial step often reveals the most obvious issues that can be quickly addressed.

Check the Power Source: Ensure that the power supply, whether it’s the battery or the electrical system, is functioning properly. Use a multimeter to check voltage levels and ensure there are no interruptions in the power flow.

Test the Motor’s Mechanical Components: Examine the motor’s internal elements such as the drive shaft, propeller, and seals. Make sure the shaft is free from obstructions, the propeller is intact, and all moving parts are properly lubricated and aligned.

Inspect the Control System: If the motor is not responding as expected, check the control system for any issues. Test the throttle, steering mechanism, and any related switches to ensure they are working as intended.

By following this step-by-step process, you can systematically identify and address any problems, restoring your motor to full functionality quickly and efficiently.

Maintaining Your Marine Motor

Proper maintenance is key to ensuring the longevity and performance of your boat’s propulsion system. Regular care and attention prevent common issues and reduce the likelihood of costly repairs down the line. By following a structured maintenance routine, you can keep your motor running smoothly for years, ensuring reliable performance when you’re out on the water.

Regular Cleaning: Clean the motor and its components regularly to prevent the buildup of dirt, salt, and debris. Saltwater can cause corrosion if left unchecked, so it’s essential to rinse the motor thoroughly after each use in saltwater. Use a soft cloth to wipe down sensitive areas to avoid damage.

Check and Replace Lubricants: Lubrication is critical for the smooth operation of moving parts. Regularly check the oil and grease levels, and replace them as needed to ensure that all mechanical components are properly lubricated. This helps reduce wear and tear and keeps the motor performing optimally.

Inspect Electrical Connections: The electrical system plays a vital role in the motor’s operation. Check for any loose or corroded connections, particularly at the battery terminals and wiring junctions. Clean any buildup and ensure the connections are secure to prevent electrical failures.

Regular Component Checks: Regularly inspect components like the propeller, shaft, and seals for any signs of damage or wear. Replacing damaged parts promptly prevents further damage and ensures that the motor runs at its best.