When it comes to maintaining a fishing boat’s propulsion system, having a clear understanding of each component is essential. Whether you’re troubleshooting or performing regular maintenance, knowing the exact role and location of each part helps ensure optimal performance. Every motor assembly is made up of intricate pieces, each contributing to the overall functionality.

Familiarity with the different sections of the system, from drive shafts to control units, makes repairs and replacements much simpler. By recognizing the most common issues that can arise and knowing how to address them, you’ll save time and effort while keeping your equipment in top condition. The process becomes much more manageable when you can visually identify and replace individual components.

With a comprehensive guide to the motor’s structure, you can approach maintenance tasks with confidence. Whether it’s replacing worn-out parts or simply making adjustments, understanding how the parts fit together is key to maximizing the motor’s lifespan and performance. Let’s explore the essential components and how to effectively manage them.

Understanding the Minn Kota Ultrex Motor

Every modern fishing vessel relies on an efficient and durable propulsion system. Whether navigating through challenging waters or making precise maneuvers, the motor’s performance directly impacts the overall experience. A well-designed motor system incorporates various mechanical and electronic components, each playing a vital role in ensuring smooth operation and control.

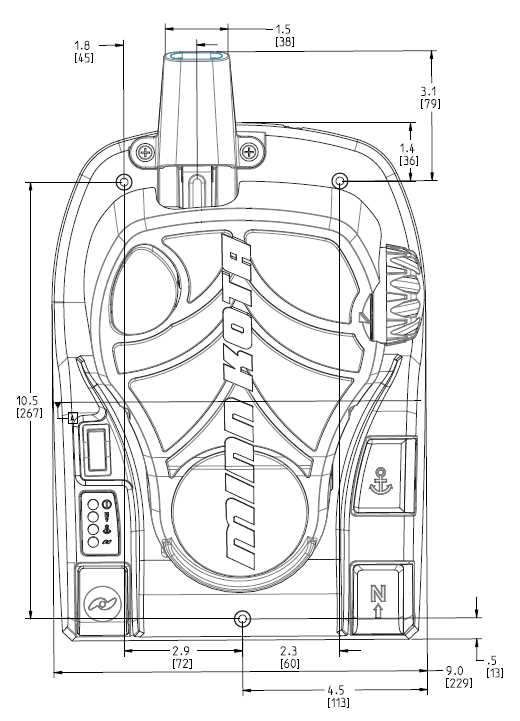

The propulsion system is typically powered by a robust drive unit that interacts with advanced steering mechanisms. The combination of motors, controllers, and power supplies works seamlessly to provide consistent thrust and direction. Key components like the shaft, propeller, and transom mount allow for precise adjustments and easy handling, even in the most difficult conditions.

Understanding the function and interaction of each piece within the assembly is crucial for maintenance and troubleshooting. Whether you’re dealing with power issues or mechanical malfunctions, recognizing the parts that need attention ensures effective repairs and minimizes downtime. Mastery of the motor’s structure allows boat owners to maintain peak performance and avoid costly repairs.

How to Identify Ultrex Parts

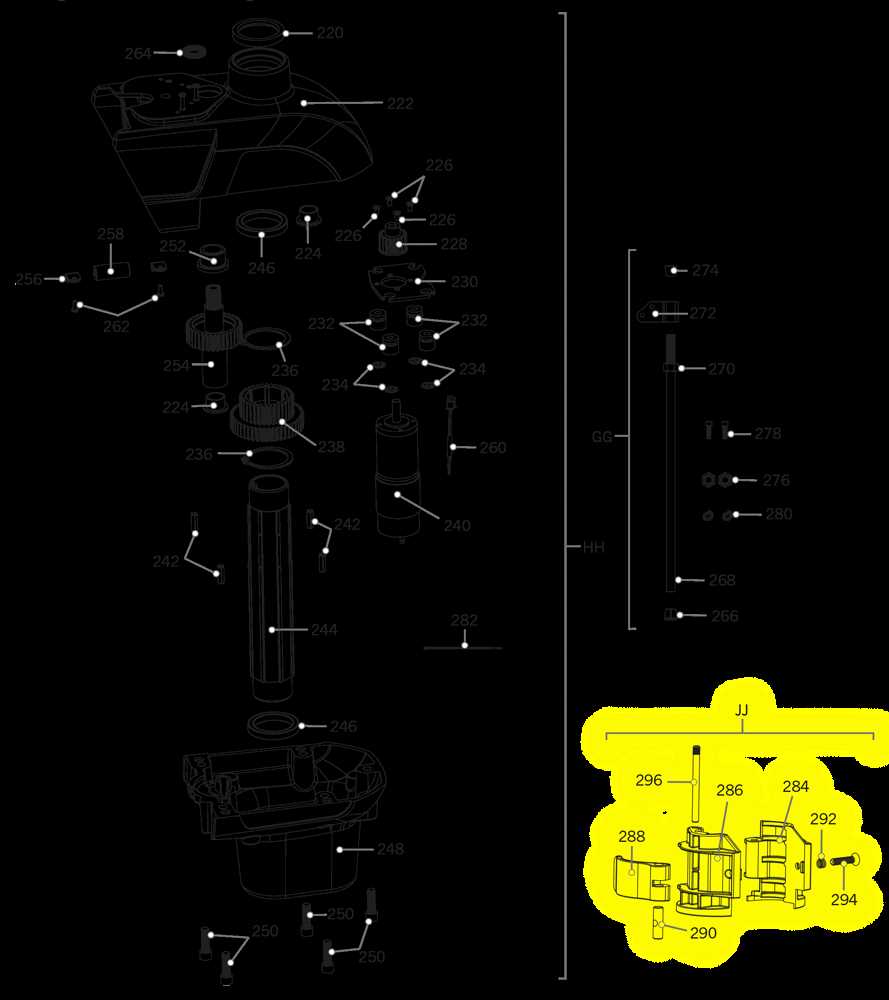

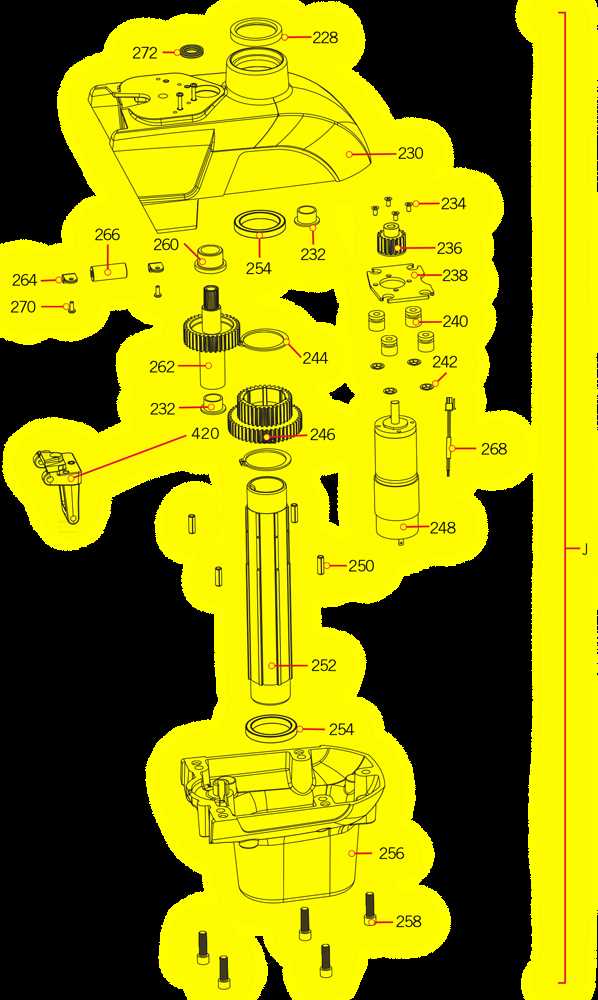

When working with any advanced trolling motor, recognizing the different components is crucial for effective repairs or upgrades. Understanding the structure of the system and the function of each individual piece allows for easier diagnosis of problems and more accurate maintenance. Proper identification also helps in selecting the correct replacement parts when needed.

Common Motor Components

Before diving into repairs, familiarize yourself with the main sections of the motor assembly. Knowing the key parts helps in quickly locating the source of an issue. Here are some of the most common elements:

- Drive Unit: This is responsible for the motor’s power and movement, typically housed within a durable casing.

- Propeller: Located at the end of the shaft, the propeller provides the thrust needed for navigation.

- Control Head: This unit allows for adjusting the motor’s speed and direction through electronic controls.

- Shaft: Connecting the drive unit to the propeller, the shaft transmits power from the motor.

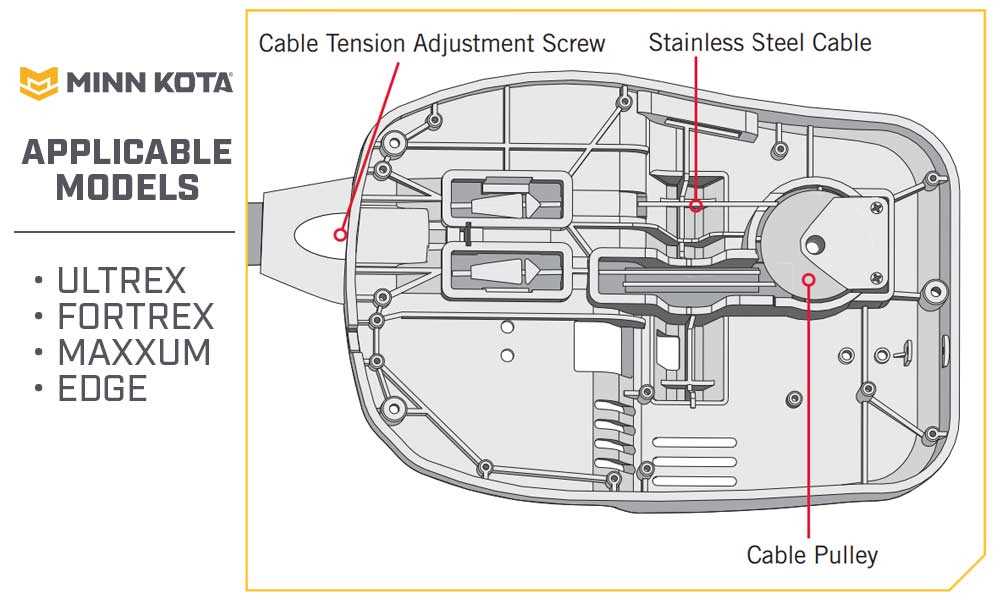

- Steering Mechanism: Allows precise turning and maneuvering of the boat in the water.

Step-by-Step Identification Tips

Once you’re familiar with the key components, the next step is to identify each piece in your system. Follow these steps to ensure proper identification:

- Inspect the motor assembly for any visible labels or model numbers that can provide useful information.

- Use a reference manual or online resources to compare parts and locate their positions within the motor.

- Look for wear and tear on each part, as it may indicate which components need attention or replacement.

- Check connections and wiring to ensure there are no loose or damaged links between the motor parts.

By methodically identifying the components and understanding their function, you can address any issues with greater confidence and ensure the motor operates at peak efficiency.

Common Repairs for Ultrex Components

Routine use and exposure to harsh environments can lead to wear and tear on key components of any trolling motor. Identifying and addressing common issues early can prevent more serious problems and extend the lifespan of your system. From electrical malfunctions to mechanical failures, knowing the typical repairs needed for your motor will help you maintain peak performance.

One of the most frequent repairs involves the propeller. Over time, the blades can become damaged from debris or rough usage. A bent or chipped propeller can significantly reduce efficiency, causing the motor to work harder than necessary. Replacing or repairing the propeller is a straightforward fix that ensures optimal performance.

Another common issue is with the steering mechanism. If the motor is not responding as expected, or if there is difficulty in turning, the problem may lie with the steering cables or electronics. A thorough inspection of these components is essential to identify potential issues like loose connections, corrosion, or electrical failure.

In addition, power-related issues are also frequent. Whether it’s inconsistent voltage supply or malfunctioning batteries, these problems can disrupt motor operation. Checking the battery terminals and wiring connections should be part of regular maintenance to prevent power disruptions. Replacing worn-out cables or cleaning corroded connections often solves these issues.

Lastly, wear on the motor shaft is another concern, especially when exposed to saltwater. Corrosion or excessive wear can cause the shaft to misalign or become damaged, affecting the motor’s performance. Regular cleaning and lubrication, along with occasional replacement of worn parts, help keep this essential component functioning smoothly.

Addressing these common issues early will not only improve the motor’s efficiency but also minimize costly repairs in the future.