Knowing the essential elements of any cutting tool is crucial for both proper usage and maintenance. Each component plays a specific role that contributes to the overall function and performance. Understanding these elements helps ensure optimal operation and longevity of the equipment.

In this section, we will explore the various components that make up a cutting tool, their functions, and how they interact. Proper knowledge of these elements allows users to identify potential issues and perform necessary repairs or replacements efficiently.

Efficient handling and careful maintenance are essential for prolonging the life of your equipment. Understanding the key components enables you to spot wear and tear before it affects performance, saving time and effort in the long run.

Understanding Key Components of a Cutting Tool

Every cutting tool consists of several critical elements that work together to ensure precision and efficiency. These components are responsible for the tool’s functionality and durability. By learning about these parts, users can better understand how to operate and maintain the equipment to achieve the best results.

Important Elements of the Cutting Mechanism

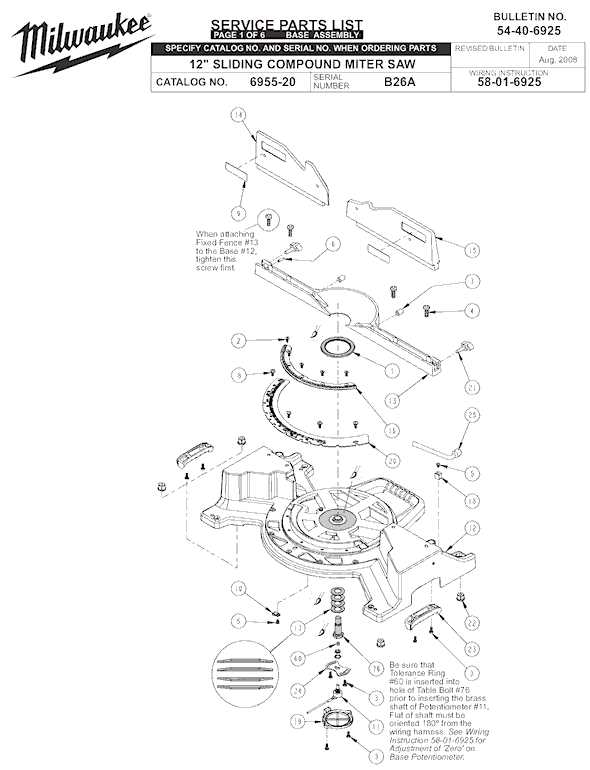

The primary function of any cutting tool is to perform precise cuts. To achieve this, several interconnected parts are involved in the cutting process, including the motor, the blade holder, and the support structure. Each part serves a specific purpose in ensuring smooth operation and accurate results. The motor provides the necessary power, while the holder ensures the blade remains stable during cutting. The structure supports the entire mechanism, maintaining alignment and minimizing vibrations.

Maintaining and Troubleshooting Key Parts

Regular inspection and maintenance of these components are essential to keeping the tool in top condition. Checking for wear and tear, cleaning moving parts, and replacing damaged elements can prevent costly repairs. Knowing how to identify common issues with the motor, blade, and structure helps troubleshoot problems quickly and efficiently, ensuring continued performance.

How to Identify Miter Saw Parts

Recognizing the different components of a cutting tool is vital for proper use and troubleshooting. Understanding each element’s role ensures the tool performs at its best and helps identify problems early on. A thorough knowledge of the key features also aids in making informed decisions during maintenance or replacement tasks.

Locating the Motor and Power Switch

The motor is often the most prominent part, located near the base of the tool. It is responsible for generating the power needed to drive the cutting action. The power switch, typically located on the handle or side of the tool, is another key part that allows users to control operation.

Identifying the Blade and Adjustment Mechanisms

The blade is the most critical component when it comes to cutting. It is typically visible in the front of the tool and can be adjusted for different cutting angles. Look for knobs or levers near the blade assembly, which allow users to modify the angle of the blade for different cuts.

Maintaining Miter Saw Parts for Longevity

Proper upkeep of tool components is essential for ensuring long-lasting performance. Regular care not only improves efficiency but also extends the lifespan of the equipment. By following a few simple practices, users can prevent wear and tear and ensure that the tool operates at its best for years to come.

Cleaning and lubricating key moving elements is crucial. Accumulation of dust, debris, or resin can hinder smooth operation and lead to damage. Routine inspection of the motor, blade holder, and adjustment mechanisms can help identify early signs of trouble, preventing major breakdowns.

Another important factor is to ensure all screws, bolts, and other fasteners are tightly secured. Loose connections can cause misalignment, affecting both precision and safety. Additionally, it’s important to keep the tool in a dry, well-ventilated space to avoid rust and corrosion over time.

Lastly, sharpening cutting tools and replacing worn-out components promptly will significantly enhance cutting quality and reduce the strain on the motor. By staying on top of these maintenance tasks, users can enjoy reliable performance from their equipment for much longer.