When it comes to maintaining and operating heavy-duty machinery, understanding the key elements and their functions is essential. Identifying each component and how they work together ensures smooth operation and prevents unnecessary repairs. This section focuses on providing clarity about the vital pieces that make up complex systems.

Effective troubleshooting starts with knowing how each piece fits into the overall structure. By familiarizing yourself with the layout and function of each element, you can easily identify potential issues and perform routine upkeep efficiently.

Proper knowledge of equipment components helps improve longevity and performance, allowing operators to address concerns proactively rather than reactively. Understanding the construction of the system leads to better control and fewer disruptions during use.

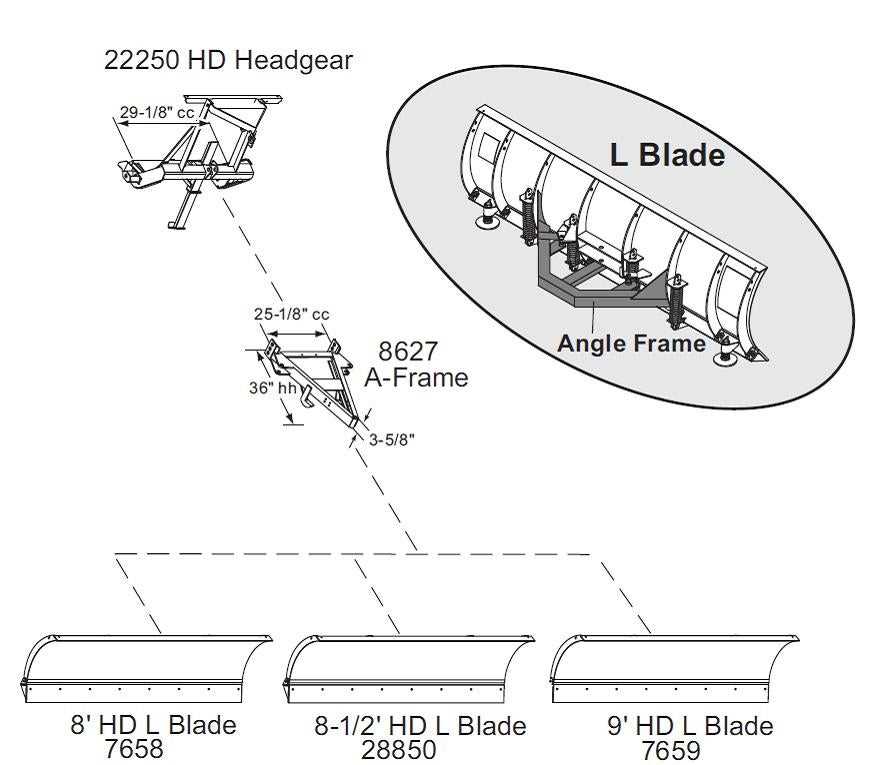

Understanding Equipment Components

Each machine consists of various integral elements that work together to ensure optimal performance. Understanding these key components and their roles is crucial for both efficient operation and troubleshooting. The interaction between each part helps in delivering the required results, making it essential to familiarize oneself with the construction and function of the system.

Key Functional Elements

Among the essential components are the framework, mechanical connections, and hydraulic systems. These pieces not only support the weight and structure but also enable movement, direction control, and operational adjustments. Familiarity with these parts allows operators to better understand the overall mechanics, making maintenance easier and more effective.

Maintenance and Troubleshooting

Maintaining the functionality of the equipment requires a keen understanding of its inner workings. Identifying common wear-and-tear issues such as fluid leaks, malfunctioning components, or loose connections can help prevent major breakdowns. Regular inspection and early detection of problems extend the equipment’s lifespan and enhance performance.

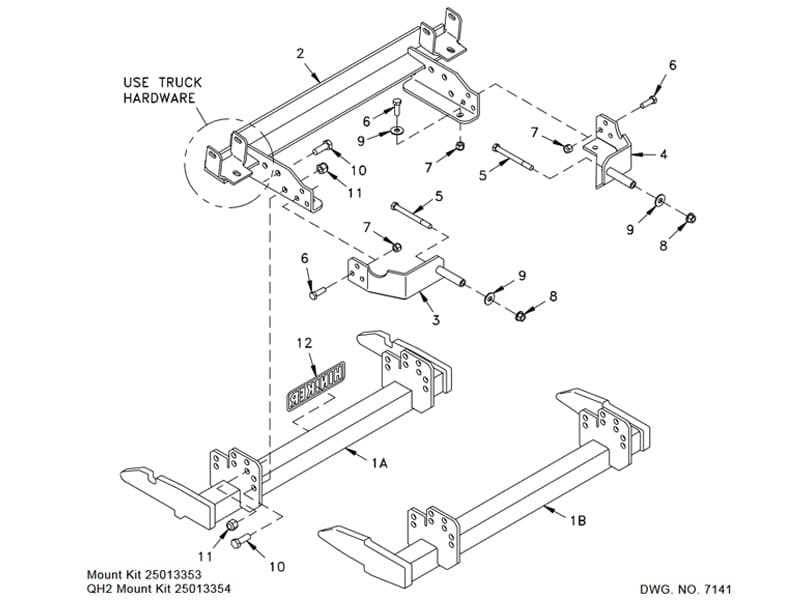

How to Read the Components Layout

Understanding how to interpret an equipment layout is essential for identifying the function and relationship between each element. These visual representations serve as a blueprint, helping users to locate, organize, and comprehend the assembly. By following a few simple steps, operators can gain a clear view of the system’s structure and troubleshoot with confidence.

First, pay attention to the labels and numbers associated with each item. These identifiers correspond to specific components, making it easier to reference them during maintenance or repairs. It’s also helpful to recognize the flow of connections between parts, as this indicates how they interact within the system.

Next, look for highlighted areas that often show where attention is needed, such as points of wear or frequent issues. Diagrams also typically display the overall scale, so operators can understand the relative size of components and their placement within the machine. With practice, interpreting these layouts becomes intuitive and a powerful tool for efficient management.

Common Issues and Maintenance Tips

Understanding potential problems and how to prevent them is vital for keeping equipment running smoothly. Routine maintenance and early identification of issues can save time and prevent costly repairs. By familiarizing yourself with the most common malfunctions, you can ensure the longevity of your machinery.

Frequent Mechanical Failures

One of the most common issues faced by operators is wear and tear on key components, such as hydraulic systems and mechanical linkages. Over time, these parts may experience stress, leading to performance issues or failure. Regular inspections to check for leaks, cracks, or loose connections help mitigate these risks.

Preventive Care and Tips

Routine lubrication and cleaning are essential steps in preventing unnecessary wear. Ensure that moving parts are well-lubricated and free of debris to maintain smooth operation. Additionally, keeping an eye on fluid levels, pressure, and component alignment can prevent major malfunctions and extend the lifespan of your equipment.