Understanding the key elements of any machine is crucial for its proper functioning and longevity. This guide focuses on the critical components that make up the mechanical system, offering a comprehensive overview for easy reference. By breaking down each section, it becomes simpler to identify how parts interconnect and contribute to overall performance.

As you delve deeper into the intricacies of the system, it’s essential to recognize how different parts play their specific roles. Whether for assembly, maintenance, or troubleshooting, having a clear understanding of each element is vital. Having access to accurate information ensures that any necessary repairs or adjustments can be done efficiently and effectively.

In this section, we aim to provide practical insights that will guide you through the essential components and their assembly process. By the end of this article, you’ll be equipped with the knowledge to handle common issues with confidence and ease.

Understanding the Key Components

To truly grasp how a mechanical system operates, it’s essential to identify and comprehend the roles of its individual elements. Each part is designed with a specific function, contributing to the system’s overall performance. In this section, we will explore the crucial components, highlighting their significance and how they work together to ensure smooth operation.

Below are some of the primary components that play an important role in the functioning of the system:

- Frame: The foundational structure that supports all other components and ensures stability.

- Motor: Powers the system, converting electrical energy into mechanical motion.

- Wheels: Provide movement and allow the system to navigate various surfaces.

- Battery: Supplies the necessary power for operation, ensuring the system stays functional for extended periods.

- Controls: Enable the user to adjust settings and guide the movement of the system.

Each of these components interacts with others to maintain seamless performance. Understanding their individual roles allows for more effective troubleshooting, repairs, and upgrades. Whether you’re assembling or maintaining the system, having a clear understanding of these parts is vital for success.

Step-by-Step Breakdown of Each Part

Understanding how every component fits into the overall system requires a clear and structured breakdown. In this section, we will go through each element in detail, explaining its purpose, installation process, and any important considerations for maintenance or replacement. By following this step-by-step approach, you will gain a deeper understanding of how these components work individually and together.

The following steps will guide you through each key element:

- First Step – Frame Assembly: The frame is the foundation of the system. Begin by carefully assembling the structural parts, ensuring they are aligned properly for stability.

- Second Step – Motor Installation: The motor is the driving force of the system. Attach it securely to the designated mounts, ensuring it is connected to the power source.

- Third Step – Wheel Mounting: Attach the wheels to the axle, making sure they are firmly in place. This is essential for proper movement and handling.

- Fourth Step – Wiring and Connections: Ensure all electrical connections are secure, particularly the wiring between the motor and the battery. Use proper insulation to avoid shorts.

- Fifth Step – Control Setup: Install the control system, which will allow for operation and adjustments. Check that all buttons or switches are functioning correctly.

By following this breakdown, you will ensure each part is installed and functioning as expected. This methodical approach helps avoid mistakes and ensures that the system performs optimally.

How to Use the Parts Breakdown Effectively

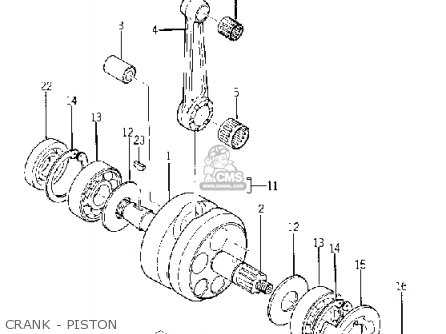

Using a detailed component breakdown is crucial for successful assembly, repair, or maintenance. It provides a clear visual representation of how each part fits into the system, making the process much easier. With proper understanding, you can ensure the components are correctly placed, identify any missing elements, and troubleshoot potential issues efficiently.

Identifying Key Components

Start by carefully reviewing the breakdown, paying close attention to the labels and identifiers for each part. These will help you understand the function of each element and how they interact with one another. Knowing the location and orientation of each piece will guide you through the assembly or repair process smoothly.

Following the Assembly Order

Use the breakdown to guide you step by step through the assembly process. Ensure that each part is placed in the correct order, as shown in the diagram. This method not only helps in avoiding mistakes but also ensures that the system functions as intended. Refer back to the breakdown whenever necessary to double-check your progress and ensure everything is aligned correctly.

Guidelines for Assembly and Maintenance

Proper assembly and ongoing maintenance are key to ensuring a system operates efficiently and lasts for an extended period. By following structured guidelines, you can avoid common mistakes and address potential issues before they become serious problems. In this section, we’ll cover essential steps and tips for both assembling your system and maintaining it over time.

Assembly Tips: Before starting, make sure you have all the necessary components and tools at hand. Carefully read through the instructions or breakdown to understand how each part fits together. Pay special attention to connections and fastenings, ensuring everything is secure but not overtightened to avoid damage.

Maintenance Advice: Regular checks are vital for keeping your system in good working order. Focus on cleaning key components to prevent dust buildup and avoid wear. Lubricate moving parts periodically to reduce friction and prevent damage. Always check for any loose connections, and address any issues promptly to keep performance at its best.

By adhering to these guidelines, you’ll ensure the system remains functional and safe to use, avoiding unnecessary repairs and ensuring longevity.

Common Issues and Troubleshooting Tips

Even with careful assembly and maintenance, problems can arise over time. Recognizing common issues early and addressing them efficiently is essential for keeping your system running smoothly. In this section, we will explore some frequent challenges users may encounter and provide practical solutions for troubleshooting.

One common issue is difficulty with movement or insufficient power. This can often be traced back to electrical connections, so check the battery and motor wiring. Ensure all connectors are secure and there are no visible signs of wear or corrosion.

Another frequent concern is unusual noise or vibrations during operation. This may indicate that certain components, such as wheels or bearings, are not properly aligned or are wearing down. Regular inspection and lubrication can help prevent these issues from becoming major problems.

If you notice that the system isn’t responding to controls as expected, the issue may lie in the wiring or the control unit itself. Inspect all connections, and if necessary, reset or replace the control module to restore functionality.

By being proactive and addressing these common issues early, you can extend the lifespan of the system and ensure a more reliable performance. Regular checks and swift action when problems arise are the keys to avoiding more serious malfunctions.