When working with powerful wood processing equipment, understanding the structure and essential elements is key to ensuring efficient operation and maintenance. These machines are designed with various mechanical components that work together seamlessly to perform heavy-duty tasks. A clear grasp of their setup can significantly extend the life of the equipment.

Familiarity with individual sections and their functions helps operators troubleshoot effectively and minimize downtime. Each piece plays a specific role, from powering the device to ensuring the safe handling of materials. A well-maintained machine runs smoother, improving both output and reliability.

Proper knowledge of the machine’s configuration not only enhances performance but also aids in carrying out routine checks and repairs. This is essential for anyone responsible for the upkeep and smooth running of large-scale machinery in wood processing operations.

Understanding Key Components of the Wood Processing Machine

In order to operate large-scale wood processing equipment effectively, it is important to understand the key elements that make up the machine. These elements work together to ensure the machine functions smoothly and efficiently. From the power system to the mechanisms responsible for handling materials, each component plays a crucial role in the overall performance.

Knowledge of these components allows operators to assess the machine’s efficiency, identify potential issues, and address them before they escalate into more serious problems. Being familiar with the structure and function of each part can also make routine maintenance more straightforward, preventing costly repairs and downtime.

Recognizing the role of each part helps in maintaining the balance between power, speed, and safety. With a clear understanding of the machine’s configuration, operators are better equipped to troubleshoot, optimize performance, and ensure the longevity of the equipment.

Key Parts in Wood Processing Equipment Design

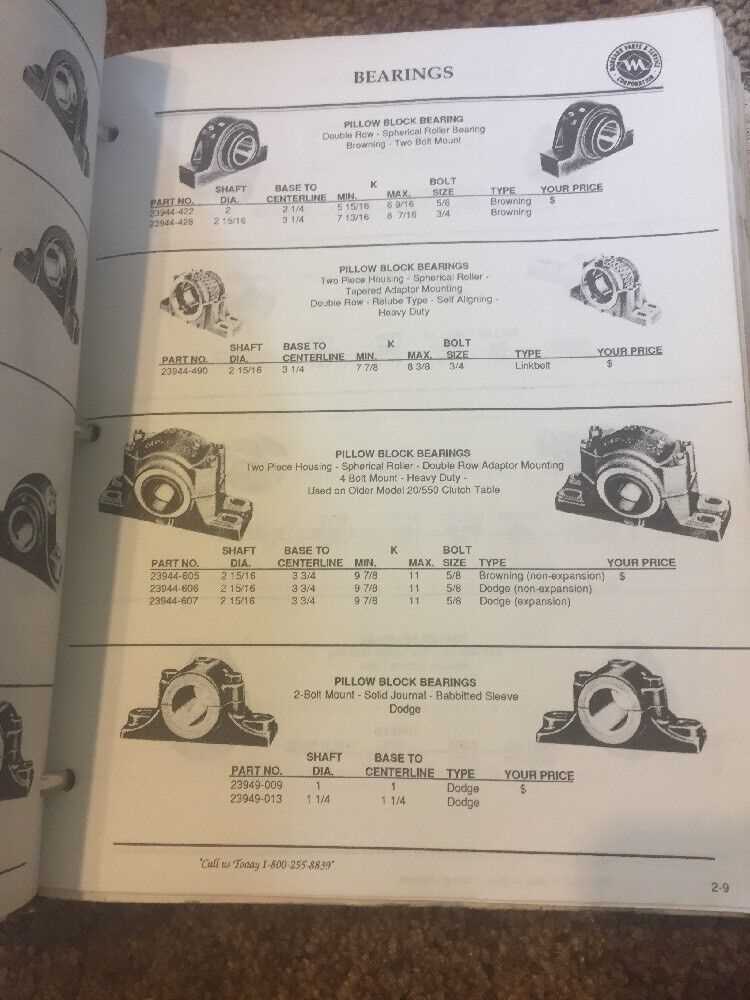

The design of wood processing machinery relies on a variety of essential elements that ensure efficiency and reliability during operation. Each component is crafted to fulfill a specific role, contributing to the overall functionality and performance of the equipment. Understanding these core elements helps to maintain the equipment in optimal working condition.

Power and Drive Mechanisms

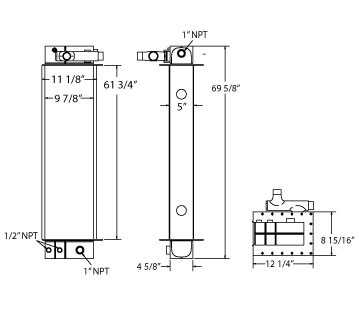

Powerful drive systems are at the heart of the machine, providing the necessary energy to operate the mechanical functions. These systems convert energy into motion, enabling the machine to perform tasks such as grinding or shredding large pieces of material with precision and speed. Ensuring the reliability of the power source is critical for consistent performance.

Feeding and Processing Mechanisms

Feeding systems are responsible for moving materials into the processing area, where they undergo the shredding or grinding process. These mechanisms are designed to handle varying material sizes and ensure smooth operation. Proper maintenance of these systems is vital to prevent clogging or damage to the internal components.

Importance of Proper Maintenance for Equipment Components

Regular maintenance of critical equipment elements is essential to ensure optimal performance and longevity. Over time, wear and tear can lead to mechanical failures, which can significantly reduce efficiency and increase repair costs. Routine checks and timely interventions help prevent such issues and keep the machinery functioning at its best.

Proper upkeep of internal mechanisms ensures that all components work in harmony, reducing the likelihood of breakdowns. This not only improves the machine’s operational lifespan but also enhances its productivity by maintaining consistent performance levels over time.

Regular inspections and cleaning of key components are fundamental practices that should not be overlooked. By addressing minor problems early, operators can avoid more severe issues and minimize costly downtime, contributing to more efficient and cost-effective operations in the long run.