Knowing how to identify and understand the different parts of your chainsaw is essential for proper maintenance, repairs, and replacements. This guide will walk you through the key elements of your tool, helping you keep it running smoothly for longer periods of time.

Important Elements of Your Tool

Chainsaws consist of several crucial components that work together to provide efficient operation. These include the engine, bar, chain, carburetor, and more. Understanding where each part fits into the overall system can help you troubleshoot issues and perform necessary repairs.

Engine and Power Mechanism

The engine serves as the heart of the chainsaw. It generates the power needed to drive the chain, and ensuring it’s in good condition is vital for optimal performance. Regularly checking spark plugs, fuel lines, and the air filter is necessary to maintain engine health.

Cutting System

The cutting system consists of the chain and bar, which are directly responsible for cutting through wood. The bar guides the chain, while the teeth of the chain provide the actual cutting action. Both parts require regular cleaning, sharpening, and replacement as they wear down over time.

Maintenance Tips and Troubleshooting

Proper care is essential for prolonging the lifespan of your chainsaw. Regular maintenance should include lubricating moving parts, cleaning filters, and tightening loose screws or bolts.

- Check the oil and fuel mixture frequently to ensure smooth operation.

- Keep the chain sharp and properly tensioned to avoid safety hazards.

- Inspect the air filter regularly to ensure maximum airflow and engine performance.

Common Problems and Solutions

If your chainsaw is not working properly, there are a few common issues to check. If the engine doesn’t start, the spark plug might need replacing. If the tool is sluggish, the fuel mixture could be incorrect, or the air filter might be clogged. Addressing these problems early can save time and repair costs.

Replacement Process

Replacing worn-out parts is an essential part of keeping your chainsaw in good condition. Always use compatible components and follow the manufacturer’s guidelines to ensure proper installation and function.

Conclusion

By understanding the essential components of your chainsaw and how to maintain them, you can extend its lifespan and ensure it continues to perform at its best. Regular checks and timely replacements will keep your tool running efficiently for many years.

Understanding the Chainsaw Layout, Key Components, and Maintenance

Every chainsaw consists of multiple interconnected elements, each serving a specific function. Understanding how these components work together ensures that your tool remains operational and efficient. This section covers the essential parts of your machine, how to locate them, and guides you on their care and replacement.

The key sections of a chainsaw include the motor, cutting system, fuel and air systems, and safety features. Each component must be correctly maintained and replaced when necessary to guarantee smooth performance. Knowing how to identify these pieces and troubleshoot issues is fundamental to keeping your tool in top shape.

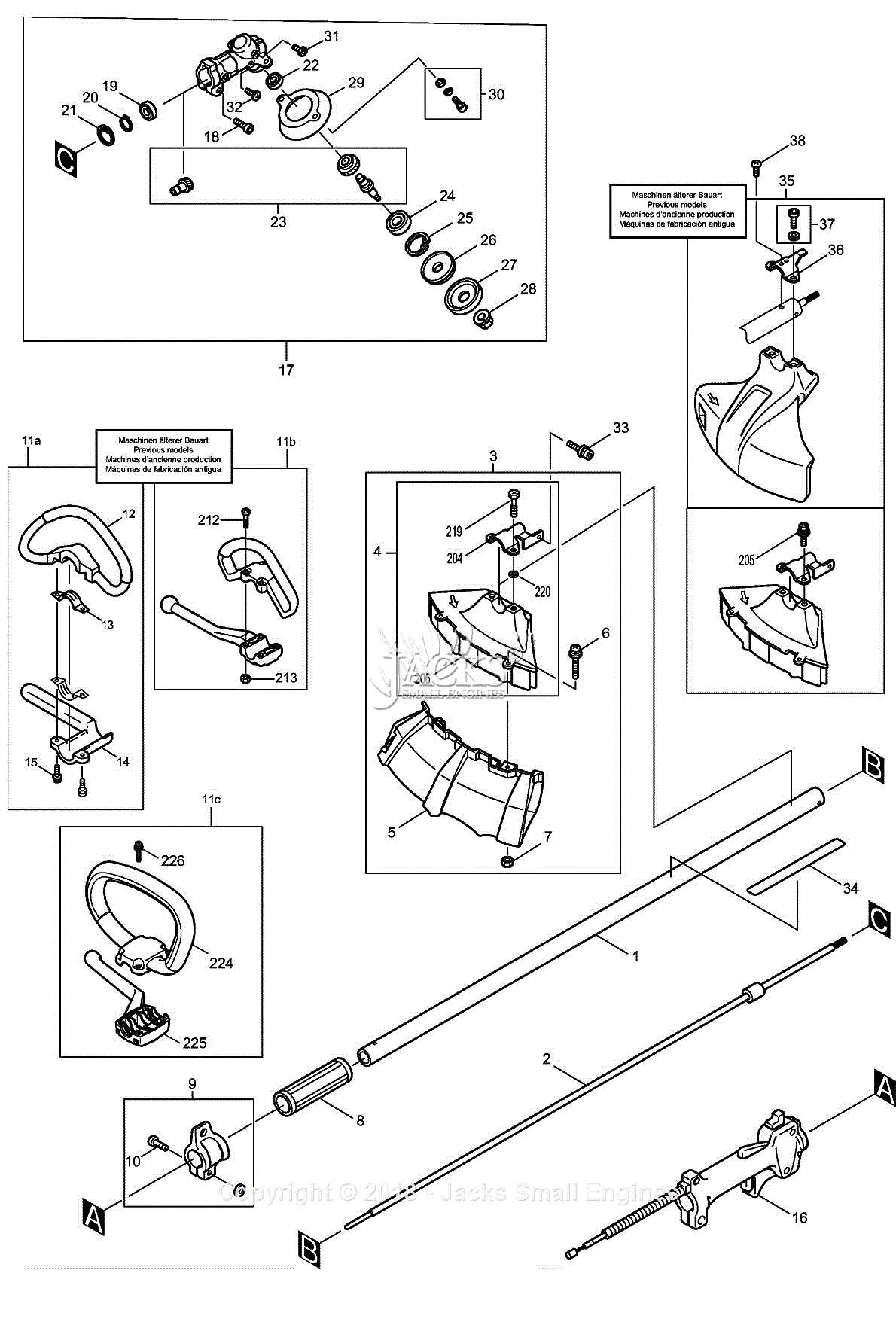

Using a visual reference for your chainsaw layout makes it easier to understand the assembly and function of each piece. These visual guides help you pinpoint where each component fits and can be invaluable when performing repairs or replacements. By following the provided diagrams or schematics, you’ll save time and effort during maintenance.

When repairs are needed, it’s important to identify the specific areas requiring attention. Common issues often involve the cutting system, air filter, spark plug, or the fuel delivery system. Familiarity with the layout helps you quickly assess the problem and take appropriate action, whether it’s cleaning, adjusting, or replacing a part.

Routine replacements, such as chain sharpening, air filter changes, and fuel system adjustments, are key to maintaining your chainsaw. A replacement guide simplifies the process by providing detailed instructions on how to handle each component. Following these steps ensures that your tool continues to perform at its best, reducing the risk of breakdowns and enhancing safety.