When it comes to maintaining heavy-duty equipment, having a clear understanding of its structure is essential. Knowing how the various components are arranged and interact allows for better performance and easier repairs. Visual aids, such as detailed breakdowns of the machine, play a vital role in ensuring that users can identify issues early and address them with confidence.

Proper maintenance starts with familiarizing yourself with the internal workings of your equipment. Whether you’re troubleshooting or upgrading, understanding how each part fits together is crucial. This knowledge not only aids in effective repair but also enhances the longevity of the machine itself.

As you work with these tools, always refer to the proper illustrations for accurate guidance. Such references provide a comprehensive view of the machine’s configuration, highlighting the most critical elements and their placement. Whether you’re looking to replace a worn-out component or simply seeking clarity on assembly, these resources offer the clarity needed to ensure smooth operations.

Understanding the Machine’s Functionality

Before diving into specifics, it’s important to grasp how this heavy-duty equipment works. Designed to handle tough tasks, this device utilizes a combination of mechanical and hydraulic systems to deliver reliable performance. By generating significant force, it breaks down large sections of wood with minimal effort. Having a clear understanding of its operations allows users to better manage its usage and address potential problems before they escalate.

Key Features and Mechanisms

This equipment features a robust design that incorporates various mechanisms to handle challenging workloads. The power unit, often coupled with hydraulic pumps, works to convert energy into splitting force. Understanding these core systems helps in identifying any wear or malfunction that might affect the overall functionality of the device. Regular inspection ensures that all parts are functioning in unison for optimal performance.

Maintenance Considerations

To keep the machine running smoothly, it’s essential to maintain its different components. Routine checks on the hydraulic system, frame, and power elements will extend its lifespan and prevent unnecessary breakdowns. By staying on top of necessary upkeep, operators can ensure that the machine continues to perform effectively year after year, handling larger workloads with ease.

Essential Components of the Heavy-Duty Equipment

Every robust machine is built from a combination of vital components that work in harmony to perform demanding tasks. Understanding these key elements is crucial for anyone looking to maintain or repair the device. Each part plays a specific role in ensuring that the system runs smoothly and efficiently. A comprehensive knowledge of these components helps in diagnosing issues and replacing parts when necessary, preventing downtime and improving overall productivity.

The primary mechanism of this equipment relies on a hydraulic system to provide the necessary force to break down large pieces of wood. Along with this, structural components such as the frame, engine, and controls all contribute to its strength and functionality. Recognizing the function of each of these parts allows users to understand how they support the overall operation, from the initiation of power to the final splitting action.

Additionally, there are smaller but equally important elements that require attention, such as safety mechanisms and maintenance points. Regular inspection and care of these components ensure that the machine remains safe and effective throughout its lifespan.

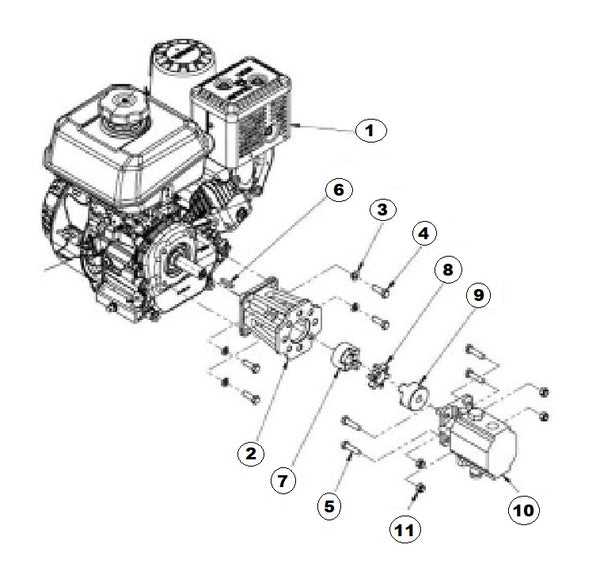

How to Read the Parts Breakdown

When troubleshooting or maintaining complex machinery, it’s essential to be able to read and understand the visual representation of its components. A well-organized schematic can help users identify each part and its relationship to the overall system. By interpreting these illustrations correctly, operators can effectively address problems, perform repairs, and ensure the proper functionality of the machine.

To begin, each section of the breakdown is typically numbered or labeled to indicate specific components. The connections between these parts are often shown with lines or arrows, illustrating how they interact. By following the provided legends or keys, users can easily match the illustrations with the physical components. This enables efficient identification and replacement of any malfunctioning or worn-out elements.

Additionally, being familiar with these visuals allows for a quicker understanding of the machine’s assembly and disassembly process. Whether performing regular maintenance or preparing for a repair, these schematics serve as an invaluable resource in guiding users through each step with precision.