Maintaining outdoor machinery requires a clear understanding of its individual elements. Whether you’re troubleshooting an issue or performing routine maintenance, knowing the key components and their functions can greatly simplify the process. This knowledge empowers users to make informed decisions and address problems efficiently.

By reviewing detailed visual representations, users can identify each part’s role and easily locate the correct replacement or perform necessary repairs. Clear instructions, combined with accurate depictions, allow for a smoother experience when dealing with mechanical challenges.

Familiarizing yourself with the structure of the machine helps in diagnosing common issues, ensuring longer-lasting performance, and reducing downtime. It’s important to approach this learning process with patience, as it enhances both the reliability and functionality of the equipment over time.

Understanding MTD 8 26 Snowblower Parts

Proper maintenance of outdoor machinery relies on a clear understanding of the individual components that make up the system. Each element serves a specific function that contributes to the overall performance and efficiency. Whether for repairs or regular upkeep, recognizing the role of each part ensures smoother operation and quicker troubleshooting when problems arise.

In this context, it’s crucial to familiarize yourself with the various sections that work together to clear snow and maintain optimal functionality. From the engine components to the auger mechanism, understanding how each part interacts allows for better diagnosis and easier replacement of faulty elements.

For anyone working with this type of equipment, knowing the physical layout and function of each component makes it easier to identify what needs attention. This not only helps with repairs but also enhances the lifespan of the machine by ensuring timely maintenance and proper care.

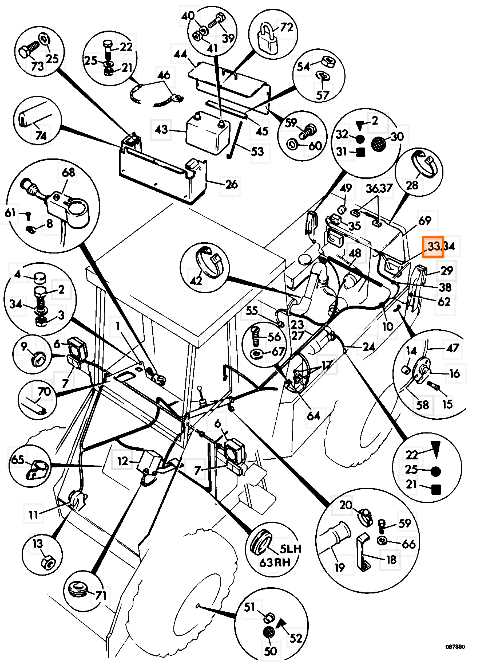

How to Read Snowblower Parts Diagrams

Interpreting technical visuals is an essential skill for anyone maintaining machinery. Understanding how to read these representations allows for quick identification of the necessary components and their arrangement. This knowledge enables users to troubleshoot effectively, make informed decisions, and carry out repairs with confidence.

Step-by-Step Process for Reading Visuals

When you open a component illustration, follow these basic steps:

- Examine the entire layout for a general overview.

- Locate key components and understand their position within the system.

- Identify numbers or labels that correspond to specific elements.

- Check the reference guide or key for part names and additional details.

Understanding Symbols and Labels

Most technical illustrations use symbols or numbers to denote individual parts. These labels are essential for proper identification and replacement. It’s important to familiarize yourself with the symbols specific to your equipment to avoid confusion.

- Look for part numbers that correspond to each section of the machine.

- Check for arrows or lines that indicate connections between components.

- Pay attention to notes that describe functionality or special instructions.

Common Repairs for MTD 8 26 Snowblower

Outdoor machinery often requires repairs to maintain its efficiency and functionality. Over time, wear and tear can lead to various issues that need attention. Knowing the most common issues and how to fix them can save time and money, ensuring that your equipment continues to perform at its best.

Common Mechanical Issues

Mechanical failures are some of the most frequent problems. These often involve components such as the engine, drive system, or auger mechanism. Identifying the root cause of the malfunction can help pinpoint the necessary repairs.

- Engine failure or difficulty starting

- Broken or worn-out belts

- Clogged or damaged auger system

Electrical and Operational Problems

Electrical issues can also arise, especially if the equipment has an electric start function. Problems with wiring, fuses, or the battery are not uncommon. Operational concerns, such as improper snow clearing or inconsistent performance, can often be traced back to minor adjustments or replacements.

- Faulty wiring or connection issues

- Battery not holding charge

- Inconsistent performance due to carburetor issues