Proper maintenance of your lawn equipment ensures its longevity and optimal performance. By familiarizing yourself with the internal structure and components of your machine, you can easily identify any issues and make necessary repairs. This section will provide essential information on how to navigate the detailed visual representations that showcase the different parts and their functions.

Learning the layout of your lawnmower is an important step in performing accurate repairs. Each component plays a crucial role in the overall functionality, and understanding their positions will make troubleshooting more efficient. Knowing where each piece fits will also help you save time and avoid costly repairs.

In this guide, we will walk through how to interpret the breakdown of your equipment, identify common faults, and provide tips for repairing or replacing components. This knowledge will help you maintain your mower in excellent condition for years to come.

Understanding the Murray M175-42 Diagram

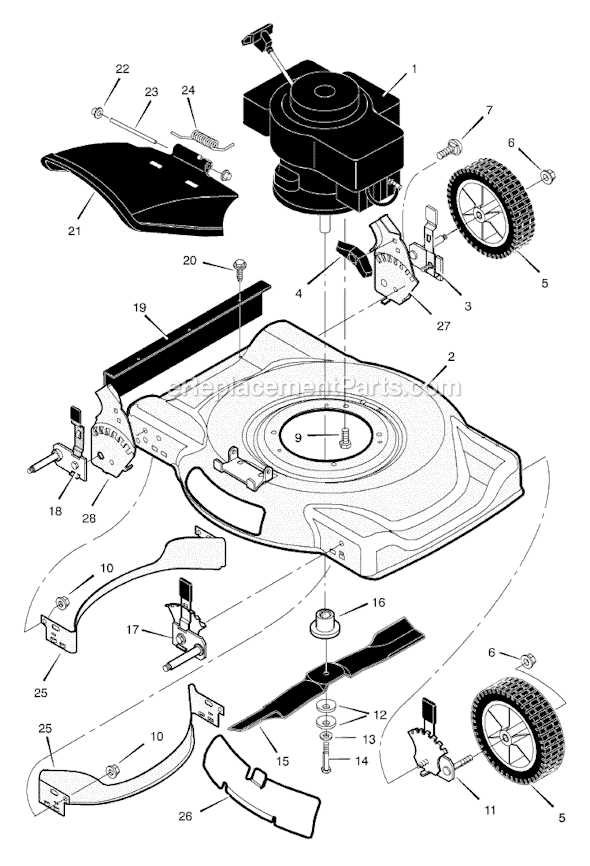

To maintain your lawnmower effectively, it is essential to understand how the various components fit together and function. A clear representation of these elements allows you to quickly assess the overall structure, ensuring each part is working properly. Familiarizing yourself with this visual guide will make identifying and addressing potential issues much easier.

The breakdown of the machine provides an organized view of its interior, helping users pinpoint specific components. By recognizing the placement of each element, you can spot signs of wear or damage and take appropriate action before problems escalate. This organized structure serves as a helpful reference when conducting repairs or replacements.

Understanding this visual reference not only speeds up troubleshooting but also aids in understanding the relationship between different components. This knowledge helps users maintain equipment efficiency, reducing the risk of breakdowns and extending the machine’s lifespan.

Identifying Key Components of the Lawn Equipment

Every piece of lawn machinery consists of several critical components that work together to ensure smooth operation. Understanding these essential parts helps in troubleshooting, maintenance, and identifying areas that may require attention. Knowing their roles and locations will make repairs simpler and more efficient.

Engine and Power System

The engine is the heart of the machine, responsible for providing the necessary power to operate various functions. Key elements such as the carburetor, fuel lines, and spark plug play a significant role in starting and maintaining engine performance. Regular inspection of these parts ensures the engine runs smoothly, preventing unnecessary breakdowns.

Cutting Mechanism and Blade Assembly

The cutting mechanism, including the blades and drive system, is crucial for achieving an even and clean cut. Blade wear and tear can affect cutting performance, making it essential to check for damage regularly. Understanding how these components are connected and how they function together will help you identify any potential issues before they affect performance.

How to Use the Visual Breakdown

Understanding how to read and utilize a visual breakdown of your equipment is key to efficient maintenance and repair. It allows you to pinpoint where specific components are located and how they are connected to one another. This knowledge makes diagnosing issues and performing repairs much easier, even for those without advanced mechanical skills.

Locating Components

Start by familiarizing yourself with the layout, paying attention to the arrangement of various sections. The diagram will clearly indicate the placement of crucial parts such as the engine, wheels, and cutting system. By referencing this breakdown, you’ll quickly identify which component needs attention or replacement.

Understanding Part Numbers and Labels

Each component on the diagram is typically labeled with a unique identifier or part number. These labels are essential for locating the correct replacement parts when needed. Be sure to note these identifiers before heading to your local supplier or searching online, as this ensures compatibility and accuracy.

Step-by-Step Guide for Maintenance

Proper upkeep of your equipment ensures its longevity and optimal performance. Regular maintenance tasks can prevent unexpected breakdowns and improve efficiency. This guide will walk you through essential maintenance steps to keep your machine running smoothly for years to come.

Preparation

- Ensure the equipment is turned off and cooled down before starting any work.

- Gather all the necessary tools and cleaning supplies you may need during the process.

- Refer to the maintenance schedule to determine the tasks that need attention.

Cleaning and Inspection

- Begin by cleaning the external surfaces to remove dirt and debris.

- Inspect critical components such as belts, hoses, and filters for wear or damage.

- Check for any loose bolts or connections that may need tightening.

- Examine the area around the engine and ensure no buildup of oil or grease is present.

Lubrication

- Apply lubricant to moving parts as per the manufacturer’s instructions to reduce friction.

- Ensure all pivot points and joints are well-oiled to maintain smooth operation.

System Checks

- Test electrical connections to make sure everything is functioning properly.

- Check fuel lines for leaks or cracks that could affect performance.

- Ensure all fluids are at proper levels, and replace any that are low or contaminated.

Final Adjustments

- Adjust settings and controls to the manufacturer’s recommended specifications.

- Test run the machine to confirm all functions are working as expected.

Common Issues with Components

Over time, equipment may experience problems due to wear and tear or improper use. Identifying and addressing common issues early can prevent further damage and extend the life of your machine. Below are some frequent issues that users may encounter with key components and how to spot them.

Wear and Tear on Moving Parts

Components that are constantly in motion are more prone to wear and degradation. Common signs of this include unusual noises, decreased performance, or difficulty in movement. Regular inspection and lubrication can help maintain the efficiency of these parts.

Electrical and Fuel System Problems

Electrical components can malfunction due to faulty connections or worn wiring. Similarly, the fuel system may face clogging or leakage issues, leading to poor engine performance. Ensuring these systems are free from obstructions and checking for any signs of damage is essential.

| Issue | Possible Cause | Solution |

|---|---|---|

| Difficulty starting | Weak battery or faulty spark plug | Replace the battery or clean/replace the spark plug |

| Excessive vibration | Loose or damaged belts | Inspect and replace belts as needed |

| Fuel leakage | Cracked fuel line or loose connections | Replace damaged lines or tighten connections |

| Overheating | Clogged air filter or low coolant | Clean or replace air filter and check coolant levels |

By keeping an eye out for these common issues and addressing them promptly, you can ensure that your equipment remains in good working condition for an extended period.