Maintaining outdoor machinery requires a clear understanding of its individual components and their functions. Identifying and replacing parts correctly ensures smooth operation and longevity. This section will help you grasp how to navigate through the essential elements of your machine, allowing you to make informed decisions during repairs or upgrades.

Knowing how each piece interacts with the rest is crucial for efficient maintenance. Whether you’re dealing with a malfunction or simply performing regular checks, having a comprehensive overview is invaluable. Accurate identification of each element will save both time and resources in the long run.

By the end of this guide, you’ll be equipped with the knowledge needed to easily locate and understand the key components, making future maintenance tasks simpler and more effective. Mastering these details not only ensures optimal performance but also extends the lifespan of your equipment.

Understanding Essential Equipment Components

Effective operation and reliable performance of outdoor machinery depend heavily on the seamless functioning of its various elements. Every machine is made up of several critical components, each playing a unique role in ensuring smooth operation. A deep understanding of these elements helps in identifying issues early, preventing damage, and maintaining efficiency throughout its lifespan.

Key Components and Their Functions

When examining the different sections of your equipment, it is important to identify the role of each part. For instance, the engine provides power, while the drive system ensures movement. The intake area typically draws in materials for processing, and the discharge system expels them after being processed. Understanding the function of each of these key systems will guide you in troubleshooting and carrying out repairs more effectively.

How Components Interact

Components do not function in isolation. They work together to ensure smooth performance. For example, the engine’s power feeds into the drive system, which then powers the movement of the device. Maintaining these connections and ensuring that each part is working in harmony is essential for keeping everything functioning as it should. Proper maintenance and regular checks on these components will prevent unnecessary breakdowns.

By gaining a comprehensive understanding of the individual pieces that make up your equipment, you can troubleshoot issues with confidence and perform maintenance tasks efficiently. Knowledge of these connections ensures that your machine remains in top condition and ready for use when needed.

Common Components and Their Functions

Every outdoor machine is composed of several key components, each serving a vital role in the overall functionality of the equipment. These elements work together to ensure that the device operates smoothly and efficiently. Understanding the function of each part will help in diagnosing issues and performing routine maintenance tasks with ease.

Engine

The engine is the heart of the machinery, providing the necessary power to drive the entire system. It converts fuel into energy, which is then transmitted to other components like the drive system and moving parts. Regular maintenance of the engine, such as changing the oil and replacing the spark plugs, is crucial to ensure its longevity and optimal performance.

Drive System

The drive system is responsible for transferring power from the engine to the wheels or other moving parts of the device. It typically includes belts, pulleys, and gears that work together to enable movement. Regularly checking the drive system for wear and tear is important, as damaged components can cause poor performance or even system failure.

Discharge Mechanism

The discharge system expels processed materials, such as debris or snow, away from the machine. It typically includes an auger and chute that work in tandem to collect and direct the material. Ensuring that the chute is clear of obstructions and the auger is functioning properly will prevent blockages and ensure efficient operation.

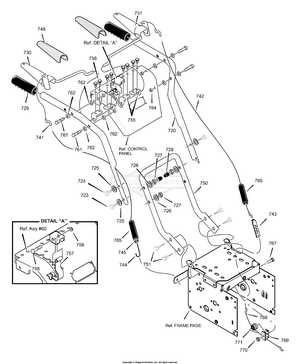

Controls

Controls allow the user to manage various functions of the equipment, from adjusting speed to controlling the discharge direction. These components include levers, buttons, and switches. Keeping the control system clean and ensuring that all connections are intact is essential for easy operation and safety.

By understanding these core components, you can keep your machine running smoothly and address issues promptly. Proper maintenance ensures that each part continues to perform at its best, minimizing downtime and maximizing efficiency. Regular inspections of these key systems can help prevent costly repairs down the line.

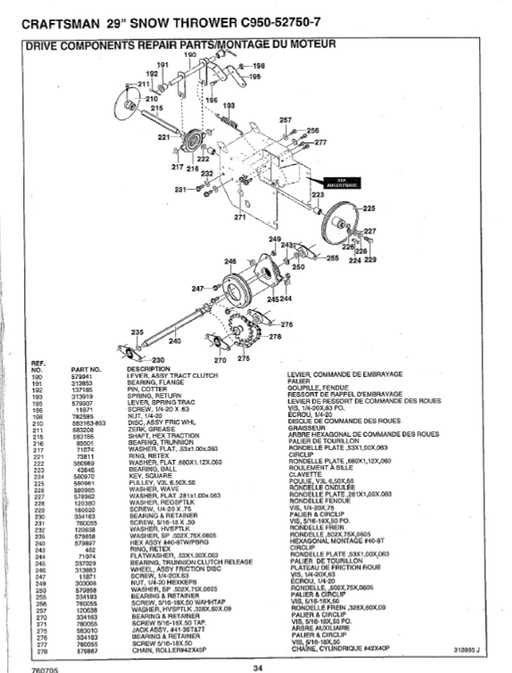

How to Read the Parts Diagram

Understanding how to interpret a schematic of your equipment is essential for effective maintenance and repairs. These illustrations provide a detailed view of how different components are arranged and connected, allowing you to locate specific parts quickly. Familiarizing yourself with the symbols and numbering used in these diagrams will significantly simplify troubleshooting and part replacement.

Key Elements to Identify

When examining a schematic, look for the following essential elements:

- Part Numbers: Each component is typically assigned a unique number for easy identification.

- Connections: Pay attention to lines or arrows that indicate how parts are connected or interact with one another.

- Component Labels: Many diagrams include labels that describe the purpose of each part, helping you understand its function.

- Views: Some diagrams show different angles of components, which can help when a part is obscured in a single view.

Tips for Effective Reading

To read a schematic effectively, follow these guidelines:

- Start by locating the main assembly or section you’re working on, and then identify the individual components connected to it.

- Cross-reference part numbers with the corresponding list to find the correct replacement parts or troubleshoot an issue.

- Look for symbols that indicate special instructions, such as arrows or icons that suggest specific actions (e.g., “rotate,” “remove”).

- If available, use the legend or key provided in the diagram to clarify any unfamiliar symbols or terms.

Once you become familiar with these techniques, reading a schematic will become second nature. Accurate interpretation of these visuals can save time during repairs and ensure that every component is correctly identified and maintained. Clear understanding of the diagram allows for more efficient and successful maintenance tasks.