Proper maintenance of agricultural machinery is essential for ensuring optimal performance and longevity. Each piece of equipment is made up of various components that work together to achieve specific tasks. Familiarizing yourself with these components and their functions can help in troubleshooting and repairs.

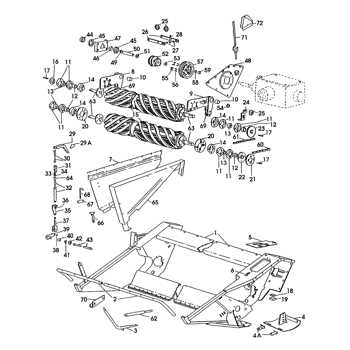

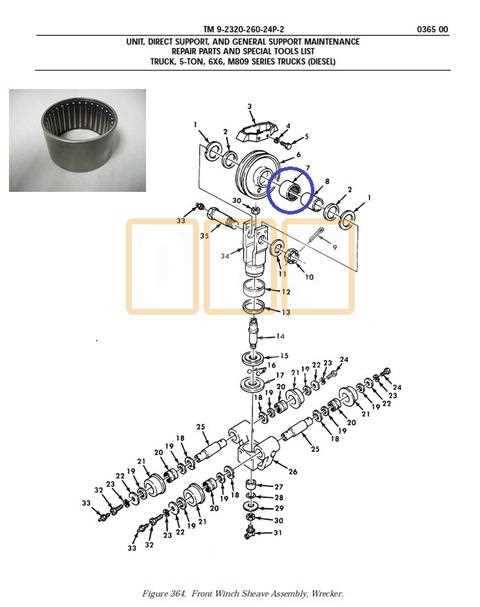

For any machine, having a clear visual reference of its structure is invaluable. A detailed illustration that labels each part allows operators to quickly identify issues, ensuring more efficient maintenance. Understanding the layout and connections of the machine can prevent unnecessary delays in the field and help with timely repairs.

In this guide, we will break down how to navigate these visual references and identify common areas of wear or failure. By doing so, you can confidently manage your equipment and keep it in excellent working condition. Whether you are replacing worn-out parts or conducting routine checks, having a clear understanding of the components is key to smooth operation.

Understanding the Agricultural Machinery Components

Familiarity with the internal structure of farming equipment is crucial for maintaining its efficiency. Knowing the different elements and how they interconnect ensures smooth operation and aids in timely repairs. By understanding the role of each part, operators can identify issues before they become costly or time-consuming problems.

Every machine used in agriculture is made up of various systems, each with specific functions. These systems work together to provide optimal performance, and a clear knowledge of each component helps in troubleshooting. Whether you’re replacing a worn-out piece or inspecting for potential issues, understanding these elements is the first step to keeping your equipment in top condition.

Proper maintenance relies on understanding the relationships between the various sections of the machine. From cutting components to moving parts, each one plays an important role in the overall operation. A detailed map of these sections makes it easier to locate and address issues, ultimately extending the life of your machinery and improving its reliability during use.

How to Read the Haybine Parts Diagram

Understanding the layout of your equipment is essential for proper maintenance and repairs. A clear visual representation of the machine’s components allows operators to easily identify each part and its function. Knowing how to interpret this reference is crucial for addressing issues and ensuring everything is in working order.

Locating Key Components

Begin by familiarizing yourself with the general layout of the machine. Major sections are often grouped together for easy identification, such as cutting mechanisms, drive systems, and control elements. Take note of how different components are positioned and connected. This helps you understand their interrelations, which is vital for diagnosing problems accurately.

Understanding Part Numbers and Labels

Each element of the machine is usually marked with a part number or code. These numbers correspond to specific items that can be ordered for replacements or repairs. By reading the labels and checking these numbers against the machine’s manual or manufacturer’s reference guide, you can ensure you are selecting the correct components when needed.

Tip: Pay attention to the orientation and alignment of each component as shown in the diagram, as this can reveal important details about the proper assembly and operation of the equipment.

Common Issues and Replacement Parts for Haybine

Farming equipment, like any machine, is subject to wear and tear over time. Identifying common issues and knowing what components to replace is essential for keeping your machinery running smoothly. Regular inspection and prompt attention to problems help extend the life of the equipment and prevent costly repairs.

Frequent Problems in Agricultural Machinery

One of the most common issues faced by operators is the wear of cutting elements, which can become dull or damaged after extensive use. Additionally, drive components such as belts and pulleys can degrade, causing the machine to lose efficiency or fail to operate altogether. Hydraulic systems may also experience leaks, affecting the overall performance of the equipment.

Replacement Components to Consider

When problems arise, replacing the damaged or worn-out parts with high-quality components is critical. Common replacements include blades, bearings, belts, and seals. Ensuring these components are compatible with your machine is vital for optimal functionality and smooth operation. Always consult the manufacturer’s manual for recommended parts to avoid compatibility issues.

Note: Regular maintenance checks and replacing parts before they fully wear out can prevent unexpected breakdowns and improve the machine’s lifespan.