The proper functioning of agricultural equipment depends on the seamless integration of various elements. In this section, we will explore the essential components that contribute to the efficiency and reliability of such machines. Understanding the layout and function of each part is crucial for maintaining performance and ensuring longevity. Regular maintenance and timely replacement are key to preventing costly breakdowns and keeping operations running smoothly.

Efficient Operation is achieved when all components work together harmoniously. The configuration of these individual elements plays a significant role in how the equipment performs under different conditions. A detailed review of each segment allows operators and technicians to quickly identify issues and make informed decisions about repairs or replacements.

Comprehensive knowledge of the machine’s structure not only aids in troubleshooting but also enhances the ability to optimize its usage. In this guide, we aim to provide a clear overview of the necessary components, with a focus on how each part interacts within the system. This will empower users to take proactive steps in maintaining their equipment and extend its operational life.

Understanding Agricultural Equipment Components

Every machine designed for agricultural work is composed of a range of critical elements that enable it to perform its intended tasks. These components work together in a precise manner to ensure the machine operates efficiently and reliably under various conditions. Familiarity with the structure and function of each part is essential for effective maintenance and troubleshooting.

To maintain optimal performance, it is necessary to understand the role of each individual component. From mechanical systems to electrical parts, each segment contributes to the overall operation of the machine. Recognizing the layout and interconnections between these elements helps operators identify potential issues before they affect productivity.

Proper care and regular checks of these components extend the life of the equipment and prevent unexpected failures. Knowing how each part functions allows users to take preventative measures, ensuring that the machinery continues to meet the demands of daily operations.

Exploring the Key Parts of Agricultural Machinery

Understanding the core components of a piece of machinery is essential for its efficient operation and maintenance. Each individual element plays a vital role in the overall functionality, and a deep understanding of these elements can prevent operational disruptions. This section focuses on the primary components that make up the framework of agricultural equipment, highlighting their functions and significance in day-to-day usage.

Mechanical Systems

The mechanical systems are responsible for powering and driving the machine. These elements often include gears, belts, and engines that work in sync to transfer energy and execute the required tasks. The integrity of these systems is essential for maintaining peak performance and avoiding unnecessary wear and tear. Regular checks and timely lubrication can help preserve these crucial parts, ensuring the machine remains operational for years.

Electrical and Control Components

Modern machinery also relies heavily on electrical systems to manage various functions such as diagnostics, power distribution, and control operations. These components include sensors, wiring, and circuit boards, all of which ensure smooth operation and responsiveness. A comprehensive understanding of how these electrical elements work together is important for troubleshooting and resolving any issues that may arise.

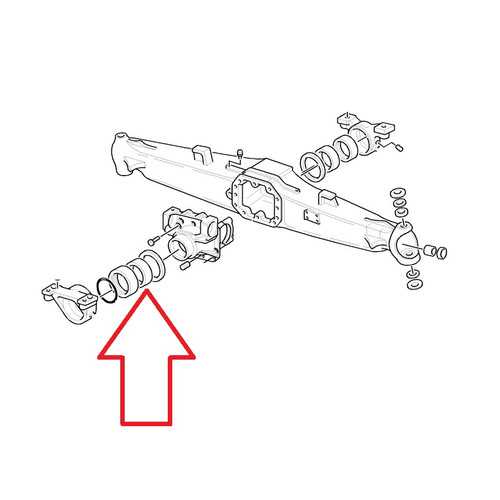

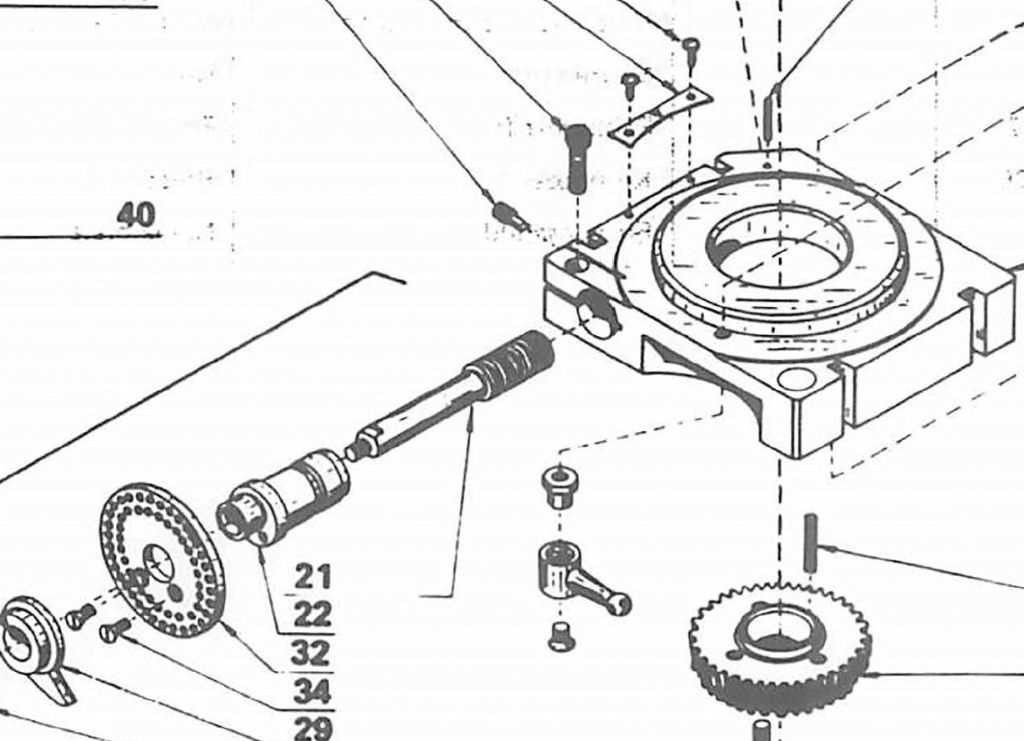

How to Use the New Holland 616 Diagram

Understanding technical drawings is essential for identifying components and ensuring proper maintenance of machinery. A clear representation of system parts can greatly enhance troubleshooting and repair tasks, providing a valuable resource for operators and technicians. By following a structured approach, you can easily locate specific elements and understand their connections.

To begin, focus on the layout of the illustration. These visuals are often divided into sections, each representing a particular function or area within the machine. The numbering system used within these illustrations helps in cross-referencing and locating replacement components or checking for potential issues.

When consulting the drawing, it’s important to first familiarize yourself with the reference codes and symbols. Each part is typically labeled with a unique identifier, making it easier to search for the exact component in a catalog or order it from a supplier. Additionally, pay attention to the orientation of the components and their relationship to one another to ensure correct installation or disassembly.

Lastly, using this guide in conjunction with the manufacturer’s manual can further clarify installation procedures, maintenance steps, and the role each component plays in the overall system. With the right tools and knowledge, this resource becomes an invaluable asset for effective machinery management.