Understanding the different components of construction machinery is essential for proper maintenance and troubleshooting. Knowing how to identify each element allows for easier repairs and ensures the longevity of the equipment. With the right information, operators can quickly locate parts and address issues without unnecessary delays.

In this guide, we will explore various sections that help break down the machinery layout. By becoming familiar with these details, technicians and operators can optimize their workflow and improve overall efficiency. With clear labels and step-by-step instructions, you’ll gain the knowledge to take better care of the machinery.

Proper maintenance relies heavily on understanding the intricate details of a machine’s internal structure. Whether it’s replacing worn-out components or conducting routine checks, this information is crucial to achieving optimal performance. Regular familiarity with the system will help you avoid costly repairs and downtime.

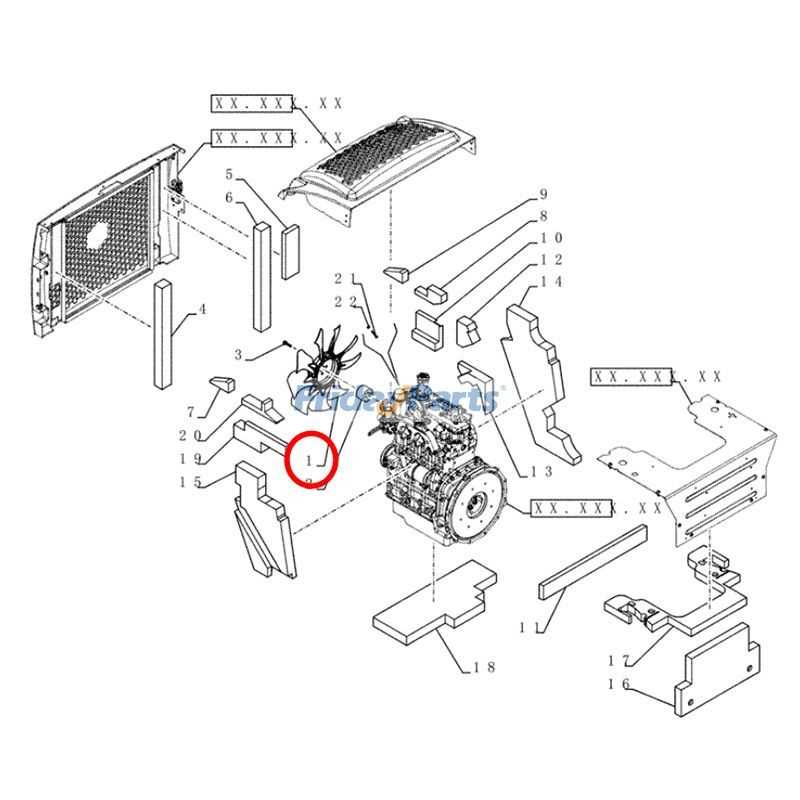

Understanding Key Components of Construction Machinery

Every machine in the construction and agricultural sectors is made up of various critical elements that work together to ensure smooth functionality. Understanding these components is key to maintaining the machinery and performing repairs efficiently. Whether you are a technician or operator, having a clear grasp of how each piece functions helps in recognizing issues quickly and making necessary fixes.

The different sections of the machine are responsible for distinct tasks, from propulsion to lifting capabilities. Each component interacts with others, making it important to have a holistic understanding of the entire system. By learning about these individual elements, you can prevent malfunctions and improve overall performance, extending the lifespan of the equipment.

Proper maintenance becomes more effective when operators can identify each part and understand its role. This knowledge empowers workers to make informed decisions, ensuring that issues are addressed before they lead to expensive repairs or downtime. A well-maintained machine, where every section is properly cared for, will provide reliable performance for years to come.

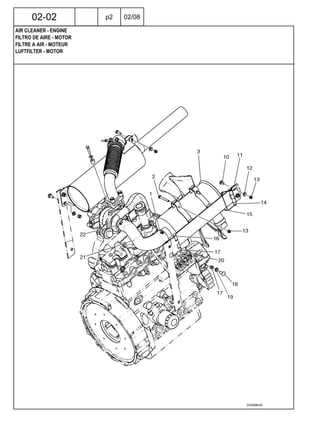

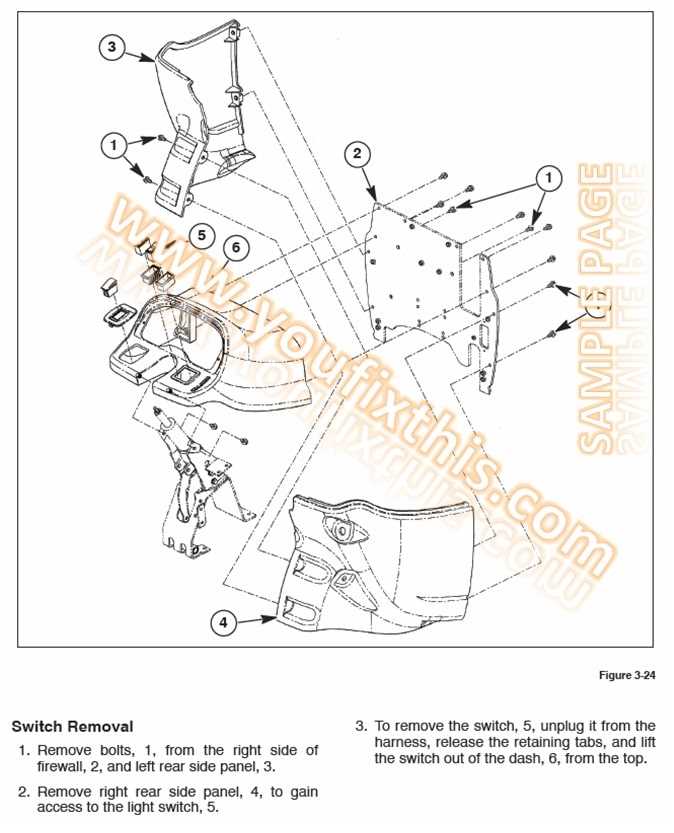

How to Read a Machinery Layout

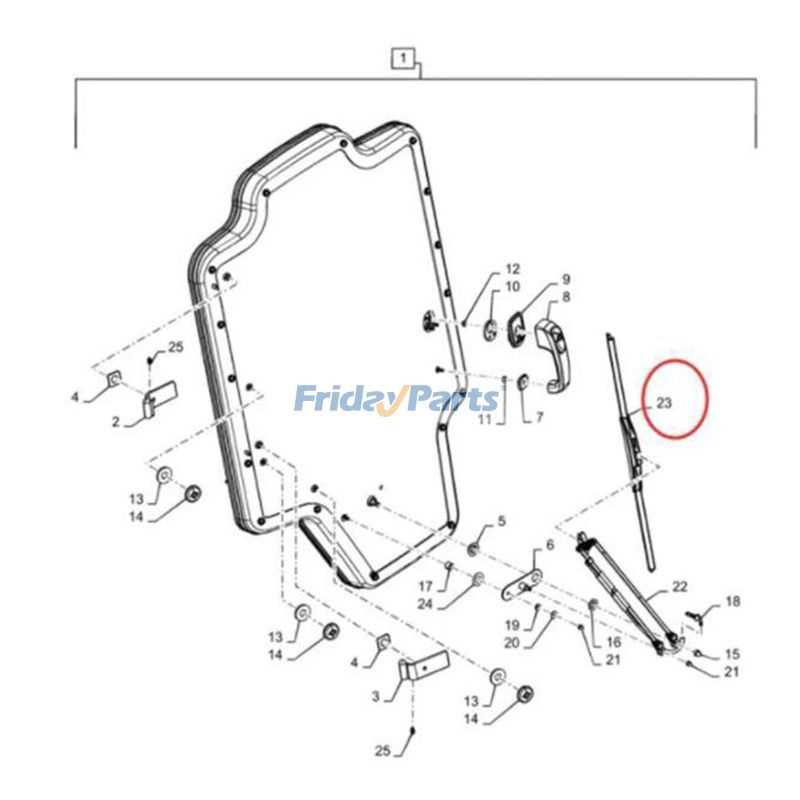

Understanding how to interpret a machine’s layout is an essential skill for anyone involved in equipment maintenance or repair. These visual guides provide clear representations of the internal and external components, showing where each element is located and how they interconnect. Learning how to read these illustrations helps in quickly identifying parts that need attention.

Familiarizing with the Symbols

In most layout guides, specialized symbols are used to represent various parts. It is important to familiarize yourself with these standard icons to accurately understand the references. Each symbol corresponds to a specific function, allowing technicians to easily navigate the diagram and pinpoint the needed components without confusion.

Following the Flow of Connections

Another key aspect of interpreting these layouts is recognizing how parts are interconnected. Understanding the flow of energy, hydraulic systems, or mechanical linkages between components helps in troubleshooting and identifying potential faults. Observing how the various sections are linked together ensures a more thorough inspection and repair process.

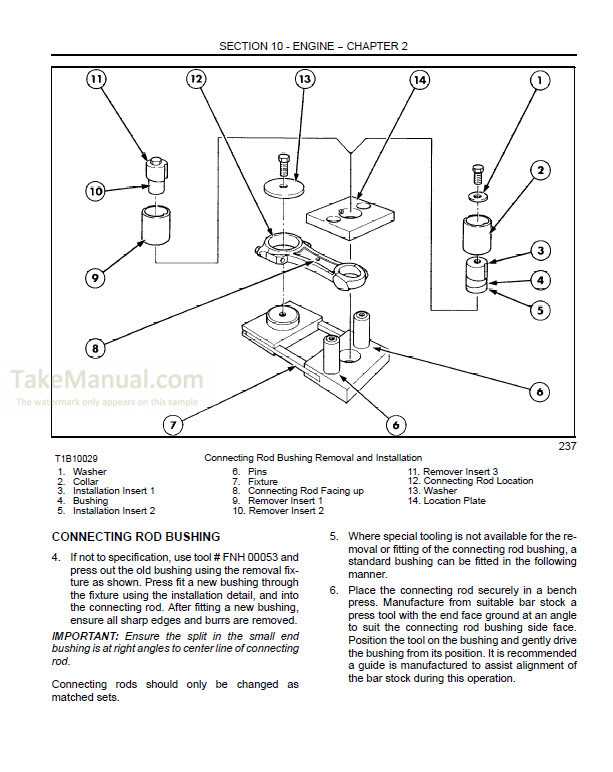

Common Components and Their Functions

Every machine consists of a variety of essential elements, each playing a specific role to ensure optimal operation. Understanding these key sections is crucial for anyone involved in machine maintenance or repair. Knowing the function of each part can help prevent breakdowns and ensure smooth performance throughout the equipment’s lifecycle.

Hydraulic Systems are among the most important components, responsible for powering various functions such as lifting, tilting, and moving the machine. They work by using pressurized fluid to transmit energy to different sections, allowing for efficient movement and control.

Engines provide the necessary power for the machine’s operation. These systems convert fuel into mechanical energy, driving all the other parts. A well-maintained engine is essential for ensuring the machine runs smoothly and efficiently for long periods.

Another vital part is the transmission system, which transfers power from the engine to the wheels or tracks, enabling movement. It regulates speed and torque, allowing the machine to perform tasks at varying levels of intensity. Proper care of the transmission ensures that the machine can handle heavy-duty tasks without issues.