When maintaining and repairing agricultural machinery, having a clear understanding of its individual components is crucial for effective troubleshooting and replacements. Knowing how different sections of the machine fit together allows for faster repairs, reducing downtime and improving productivity.

Whether you are an experienced mechanic or a farm owner looking to handle minor repairs on your own, familiarity with the machine’s structure helps ensure that each part functions as intended. This understanding can also save money on costly professional services by empowering you to perform routine fixes independently.

In this guide, we will explore how to interpret various schematics, identify essential parts, and address common issues that may arise during operation. By mastering this knowledge, you can ensure your equipment operates smoothly and lasts longer.

Understanding New Holland TC30 Tractor Parts

When working with farm machinery, it is essential to have a solid understanding of the different components that make up the equipment. Each piece plays a vital role in ensuring the smooth operation of the machine, from the engine to the smaller internal mechanisms. By knowing the function of each section, it becomes easier to diagnose problems and perform maintenance.

For any tractor, identifying the location and purpose of individual components is key to effective repairs. A clear overview of these elements can help in troubleshooting issues like engine failures, hydraulic problems, or transmission malfunctions. Recognizing the exact part in need of replacement also makes ordering the correct item more efficient, saving time and reducing costs.

In this section, we will break down the major components of a tractor and provide insight into how they interact. Understanding these elements helps extend the longevity of the machine and ensures that each operation is carried out effectively and safely.

How to Read the TC30 Parts Diagram

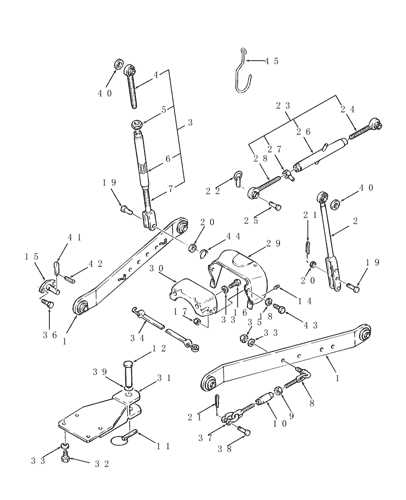

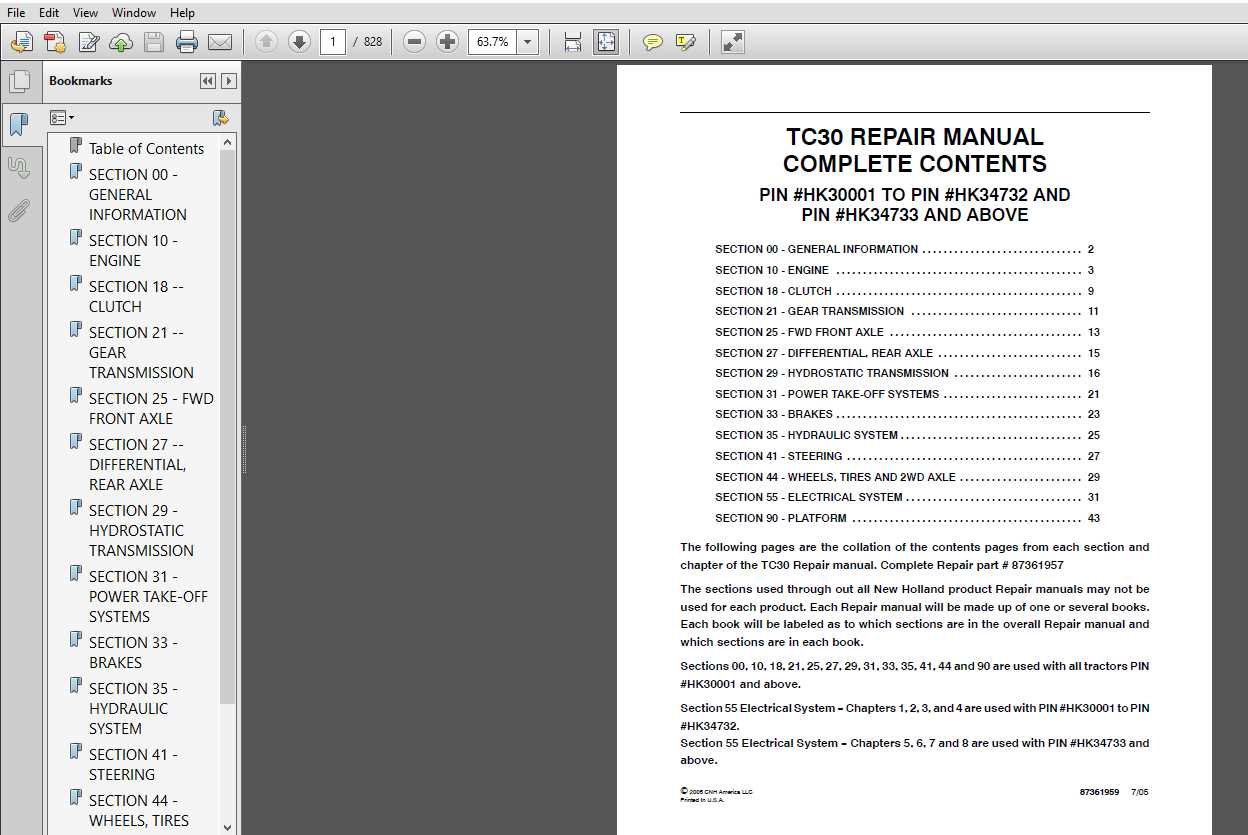

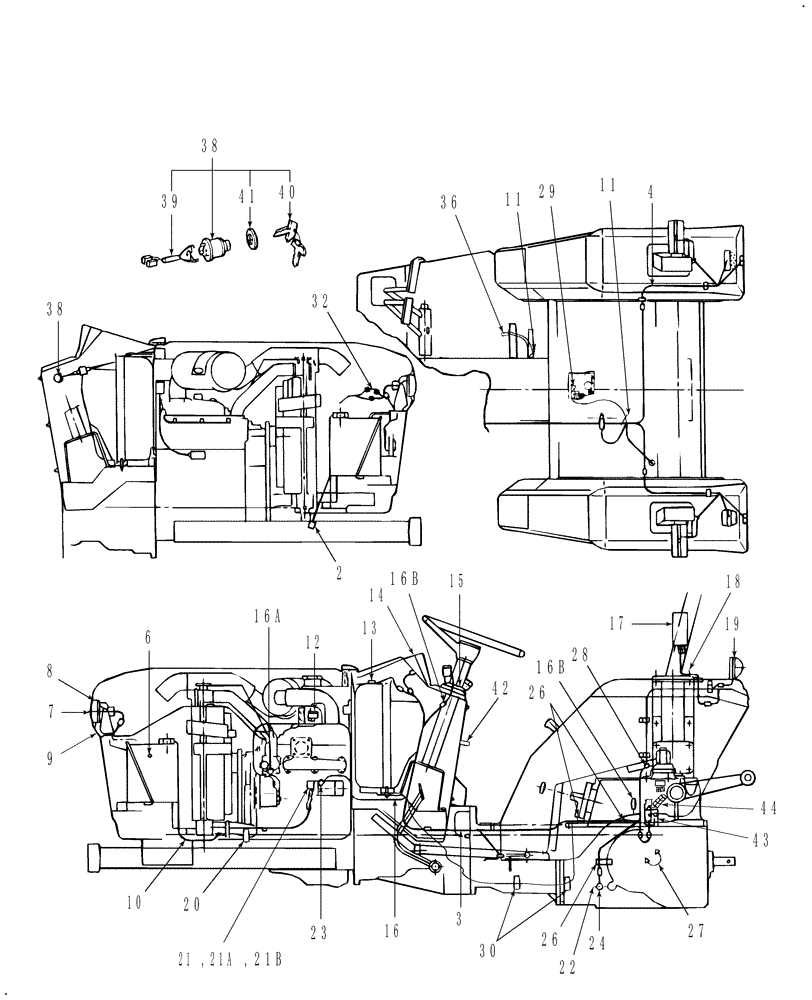

Reading a technical schematic for machinery can be a valuable skill for anyone involved in maintenance or repair. These illustrations offer a detailed view of a machine’s structure, showing how various components fit together and interact. Understanding these visuals allows for more accurate identification of problematic areas and simplifies the process of ordering replacement components.

Typically, these schematics will include numbered references that correspond to specific pieces. Each item is often accompanied by a part number and a description, which makes it easier to find the correct replacement or repair tools. Recognizing the layout and how to navigate through the diagram is crucial for efficient problem-solving and repair work.

As you become familiar with reading these diagrams, you will be able to identify both major and minor components, understand their connections, and quickly pinpoint potential issues. This knowledge is essential for anyone looking to maintain or restore farm machinery effectively.

Common Issues and Parts Replacement for TC30

Machinery, no matter how well maintained, can experience wear and tear over time. Identifying common malfunctions early can prevent more serious damage and costly repairs. A proactive approach to understanding potential issues helps ensure the equipment runs smoothly and efficiently.

One of the most common issues encountered is engine failure, often caused by clogged filters or issues with the fuel system. Similarly, hydraulic problems, such as leaks or pressure loss, are frequent and can affect the overall performance. Identifying the exact part at fault and replacing it quickly can prevent further damage to the system.

Another area to watch is the transmission system, which may experience issues such as difficulty shifting or unusual noises. In these cases, checking the fluid levels and replacing worn components like seals and gaskets can often resolve the problem. Regularly inspecting these critical parts and addressing wear promptly can extend the life of the machine and improve its performance.