Generators are vital for powering various devices and systems when the main electricity source is unavailable. To ensure their long-term functionality, understanding the internal elements and their organization is essential. A well-maintained machine can perform efficiently, preventing costly repairs and downtime.

In this section, we will explore the essential components that make up a typical generator, offering a clear overview of each part’s role. Having a good grasp of these elements not only aids in troubleshooting but also in conducting regular maintenance tasks to keep the equipment running smoothly.

Familiarity with the internal structure and the relationships between components allows users to identify problems quickly and determine the necessary repairs. With the right knowledge, even complex issues can be resolved effectively, ensuring reliable performance for years to come.

Understanding Generator Components

Every generator consists of multiple key elements that work together to convert mechanical energy into electrical power. These components are organized in a specific manner, ensuring smooth operation and efficiency. A thorough understanding of each part’s function helps users maintain optimal performance and troubleshoot potential issues effectively.

Essential Internal Components

The core of any generator includes the engine, alternator, and various control systems that regulate its performance. The engine is responsible for driving the alternator, which generates electricity, while the control systems monitor parameters like fuel consumption and output. Each of these components must be maintained regularly to ensure consistent and reliable power production.

Supporting Systems and Accessories

In addition to the main functional components, generators include various supporting systems such as cooling, exhaust, and lubrication. These systems help regulate temperature, reduce harmful emissions, and maintain fluid levels for smoother operation. Understanding the role of these accessories is just as important as knowing how to care for the primary components.

Key Parts of Generator System

A generator consists of various essential components that work together to ensure reliable power output. Each part plays a specific role in the operation of the unit, and proper knowledge of these components can significantly improve maintenance practices and troubleshooting efforts. Understanding the function of each key element helps keep the equipment running smoothly and efficiently.

Engine and Alternator

The engine is the heart of the system, converting fuel into mechanical energy. It drives the alternator, which is responsible for producing electrical power. Together, these two components form the core of the generator’s operation, making their proper care and maintenance crucial for optimal performance.

Fuel and Cooling Systems

The fuel system ensures a steady supply of energy to the engine, while the cooling system prevents overheating by regulating the temperature. These systems must be carefully monitored to avoid performance issues, as malfunctions in either can lead to significant downtime or damage to the generator.

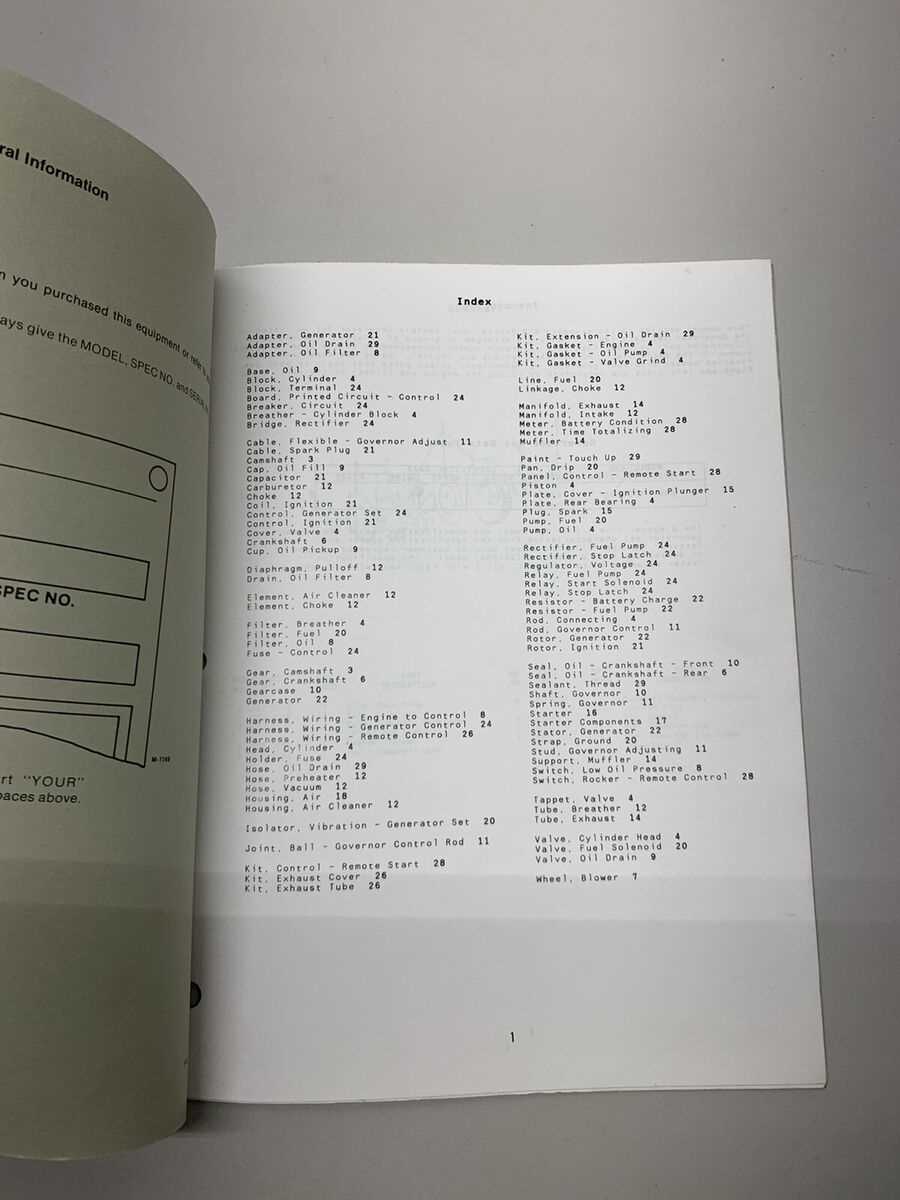

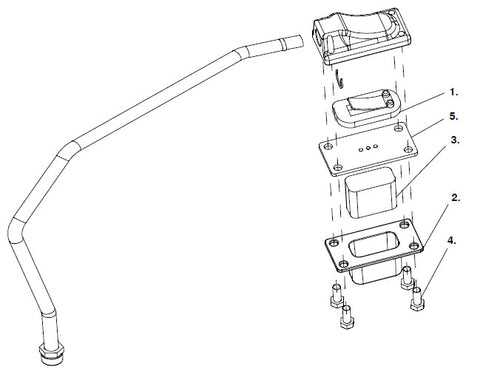

How to Read Generator Schematic

Understanding the layout of a generator’s internal components is essential for efficient maintenance and repairs. A schematic or blueprint provides a visual representation of how the parts are arranged and interconnected. Being able to read this type of diagram allows technicians and users to quickly identify the location of each part and comprehend its function within the system.

To interpret a schematic properly, start by familiarizing yourself with the symbols used to represent different components. Each part has a standard symbol that is consistently applied across diagrams. Next, pay attention to the lines that connect these symbols, as they show the flow of energy or mechanical movement between parts. Recognizing these connections will help in understanding the relationships between components and assist in troubleshooting potential issues more effectively.