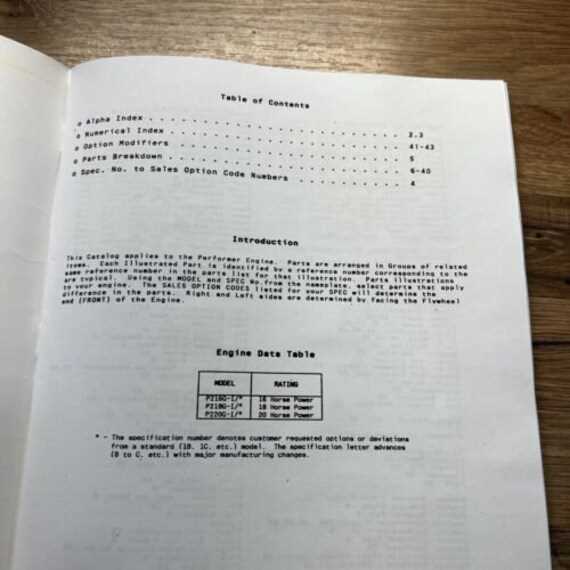

Understanding the structure and organization of an engine is essential for its proper maintenance. By examining the various elements that make up the machinery, users can ensure efficient performance and prevent potential issues. This section provides insight into the key components, their functions, and the necessary steps for maintaining them effectively.

Identifying each individual component allows for better troubleshooting and replacement when necessary. By studying a detailed overview, one can easily recognize worn-out parts and replace them in a timely manner, ensuring the engine operates at peak efficiency.

Proper knowledge of the engine layout is also crucial for maintenance tasks. Knowing the specific roles of each part will aid in proper care, reduce downtime, and extend the lifespan of the equipment.

Understanding the Engine Components

Each engine consists of numerous key elements that work together to ensure smooth operation. Understanding these components is crucial for anyone looking to maintain or troubleshoot machinery. These components, although varying in shape and function, all play vital roles in the engine’s overall performance and longevity.

From the power generation system to the control mechanisms, recognizing each part’s function is the first step toward proper maintenance. By gaining an understanding of the connections between various components, you can more easily identify potential issues and address them effectively.

Familiarity with the core components allows for quick, informed decisions when parts wear out or malfunction. A thorough knowledge of these elements can help keep the equipment running optimally for years.

Identifying Key Parts in the Diagram

When examining the layout of an engine, it is essential to be able to recognize the critical components that contribute to its function. Each section of the machinery is designed to perform a specific task, and understanding their arrangement can help in effective diagnostics and repairs.

Each part is marked and positioned in a way that reflects its role in the system. By reviewing the layout, you can easily spot the components responsible for power generation, control, and cooling. This knowledge is invaluable when it comes to performing maintenance or making replacements.

Familiarizing yourself with the key elements enables you to quickly identify what may need attention during an inspection. Proper identification ensures that you focus on the right areas, minimizing downtime and maintaining the machinery in optimal condition.

How to Replace Engine Components

Replacing worn-out or damaged elements is a crucial step in maintaining the efficiency and longevity of machinery. This process requires careful attention to detail to ensure each replacement part fits properly and functions as intended.

Before beginning the replacement, follow these general steps to ensure a smooth and successful procedure:

- Turn off the engine and disconnect any power sources to avoid accidents.

- Identify the faulty component by reviewing the engine layout and recognizing which part needs replacement.

- Acquire the correct replacement part that matches the specifications of the existing component.

- Remove the damaged part carefully, using the appropriate tools to avoid damaging surrounding components.

- Install the new component, ensuring it is securely fitted and connected to the appropriate sections.

- Test the system to verify that the replacement part is functioning correctly and that the machinery is running smoothly.

Following these steps will help you replace components efficiently, ensuring your equipment continues to operate without unnecessary interruptions.