Effective operation and maintenance of a warehouse lifting tool depend on understanding its internal structure. Each component plays a critical role in ensuring smooth functionality and durability over time. A clear knowledge of how these elements interact can greatly enhance both efficiency and safety during usage.

Visual aids are valuable tools in helping operators and maintenance personnel identify and troubleshoot potential issues. By learning to recognize the different elements, one can pinpoint sources of malfunction or areas requiring regular checks and upkeep.

Regular attention to the machinery’s individual components is essential for its longevity. Understanding their role and condition allows for more informed decisions during repairs and replacements, ultimately reducing downtime and improving overall productivity.

Understanding Key Pallet Jack Components

To ensure efficient operation, it’s crucial to have a solid understanding of the essential elements that make up a warehouse lifting tool. Each part serves a unique function, contributing to the overall effectiveness of the system. Recognizing how these components work together can improve safety and reduce the risk of malfunction.

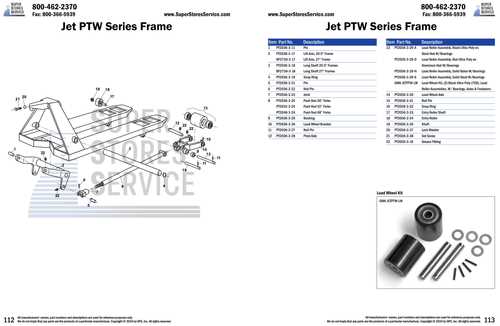

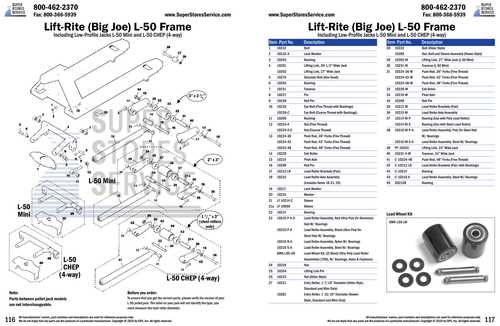

Basic Structural Elements

The primary framework of the equipment provides the necessary support for the entire mechanism. This structure is designed to withstand heavy loads while ensuring stability and control. Key components like the wheels and frame are integral to the movement and load-bearing capacity of the tool.

Operational Components

Several elements are responsible for the tool’s maneuverability and functionality. The control mechanism, typically a handle or lever, interacts with the lifting system to raise and lower items. Understanding how these components function together allows for smoother operations and more effective handling of goods in the warehouse.

How to Identify Essential Parts on a Diagram

Understanding the layout of a warehouse tool’s components is critical for anyone involved in its operation or maintenance. A visual representation of these elements can help identify each part, providing clarity on their roles and locations. By recognizing the various components, you can easily troubleshoot or perform necessary repairs.

Recognizing Major Components

The first step in interpreting a schematic is identifying the larger, foundational elements that are typically visible. These often include the frame, wheels, and lift mechanism. Once you familiarize yourself with their placement, it becomes easier to spot supporting features that work in tandem with them.

Focus on Smaller, Detailed Parts

In addition to the primary components, it’s essential to understand the smaller, intricate elements shown in the diagram. These parts, such as the hydraulic system or control mechanisms, are vital to the smooth operation of the tool. Recognizing their location and function can help you pinpoint issues and ensure proper functioning.

Importance of Regular Pallet Jack Maintenance

Maintaining warehouse lifting tools is crucial for ensuring their long-term performance and reliability. Routine checks and servicing can help identify potential issues before they develop into more significant problems, minimizing downtime and repair costs. Regular maintenance ensures that the tool continues to operate smoothly and safely under heavy workloads.

Preventive care is essential for extending the lifespan of the equipment. Regularly inspecting components such as the lifting system, wheels, and controls helps detect wear and tear that could compromise the tool’s functionality. Addressing these concerns early can prevent costly repairs and replacements.

Consistency in maintenance is key to avoiding unexpected failures. By following a scheduled upkeep routine, operators can ensure that all critical parts are functioning optimally, reducing the risk of malfunctions during operation and improving overall productivity in the workplace.