Maintaining a pool filtration system requires knowledge of its individual components and how they work together. Whether you’re dealing with routine maintenance or more complex repairs, understanding the system’s layout is essential. Each piece plays a crucial role in ensuring the filter operates smoothly and efficiently.

Identifying key elements of the system and learning how they interact will allow you to address issues quickly. Recognizing where problems arise helps prevent further damage and minimizes downtime. With the right tools and knowledge, performing repairs becomes more straightforward.

In this guide, we will explore the most important components of a pool filtration system, how to spot common issues, and what you need to replace when things go wrong. By understanding these vital aspects, you’ll be able to keep your system running at its best for a longer period.

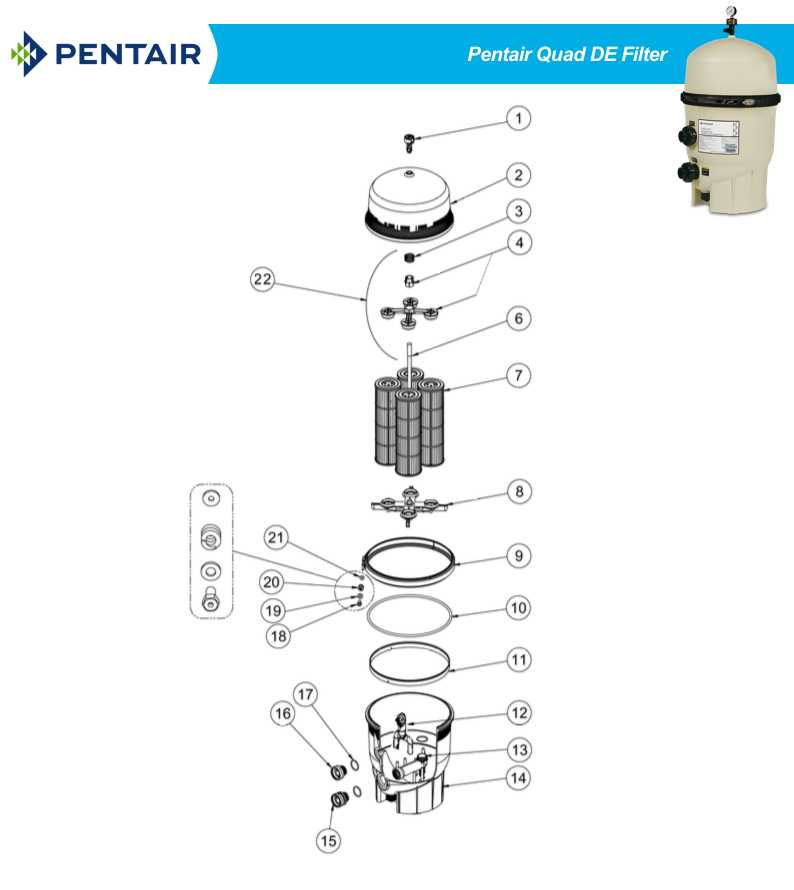

Pentair CCP520 Diagram Overview

Understanding the layout of a pool filtration system is essential for both maintenance and troubleshooting. By examining the system’s configuration, you can identify how each component functions and interconnects, helping to spot issues or streamline repairs. The clearer your understanding of the internal structure, the more efficiently you can manage potential problems.

In this section, we break down the various elements that make up the filtration unit, providing a visual and descriptive representation of each key component. This comprehensive overview will guide you in identifying essential parts, understanding their roles, and knowing where to focus your attention when repairs or replacements are needed.

Understanding Key Parts for Maintenance

Regular upkeep of your pool filtration system relies on recognizing the critical components that keep the system running efficiently. A deep understanding of each key element ensures you can identify wear and tear early, preventing potential issues before they disrupt the filtration process.

Identifying the Essential Components

The system consists of various pieces that work in unison to clean and filter water. From the filter media to the valves and pumps, each part serves a specific function. Knowing how they contribute to the overall performance can save time when diagnosing problems.

Maintaining and Replacing Key Elements

Maintenance often involves replacing worn-out seals, cleaning clogged parts, or swapping out filters. Understanding the role of each component makes these tasks easier and ensures that you address the right parts at the right time. Regular checks will prolong the life of your system and improve its efficiency.

How to Identify Key Components

Knowing how to properly identify and distinguish between the essential elements of your filtration system is crucial for effective maintenance and repairs. Each component plays a specific role in ensuring optimal performance, and understanding these functions will help you address problems faster and more accurately.

Visual Inspection and Markings

Many critical components feature markings or labels that help identify them. A close inspection of each piece can often reveal part numbers, manufacturer details, or other indicators that distinguish one element from another. Familiarizing yourself with these markings will allow for more accurate troubleshooting and component replacement.

Referencing Technical Documents

Having access to technical documentation or manuals is a valuable resource for identifying system elements. These documents usually include diagrams and specifications that describe each component’s placement and role in the system. For convenience, you can use the following table to match common elements with their corresponding functions:

| Component | Function |

|---|---|

| Filter Media | Captures debris and particles from the water. |

| Pump | Circulates water through the filtration system. |

| Valve | Controls water flow and directs it to different parts of the system. |

| Seal | Prevents leaks and ensures a secure connection between components. |

Step-by-Step Breakdown of Parts

Understanding the order of assembly and disassembly of your filtration system is key to effective troubleshooting and maintenance. Breaking down each component step-by-step ensures that you can address issues methodically and reduce the risk of missing important details during repairs.

Follow these steps to gain a clear understanding of the major components involved in the system:

- Turn off the system – Before starting any work, ensure that the system is completely powered off to avoid any accidents.

- Remove the outer cover – Gently detach the outer casing to expose the internal components, being careful not to damage any seals or connections.

- Check the filter media – Inspect the filtration material for signs of wear or blockage. Replace if necessary.

- Examine the pump – Inspect the pump for leaks, cracks, or debris that could hinder its performance. Clean or replace as needed.

- Inspect the valves – Ensure that the valves are functioning smoothly and not clogged with debris. Test their movement to confirm proper operation.

- Check seals and gaskets – Look for any damage or signs of wear that could cause leaks. Replace them if necessary.

- Reassemble the system – Once all components have been inspected and replaced, carefully reassemble the system, ensuring all parts are securely connected.

By following this breakdown, you can efficiently identify and address issues, ensuring your filtration system remains in top condition.

Common Issues and Replacement Parts

Filtration systems are susceptible to wear and tear over time, and understanding the common issues that arise can help you take proactive measures. Identifying these problems early can prevent system breakdowns and ensure the longevity of the components. Knowing which parts to replace and when can save both time and money.

Here are some common issues that may occur with your filtration system:

- Clogged filter media – Over time, the filter material can become clogged with dirt and debris, reducing efficiency. Replacing the filter media is necessary to maintain proper water flow and cleanliness.

- Leaking seals – Seals and gaskets can degrade due to constant pressure and exposure to chemicals. Replacing worn seals is crucial to prevent water leakage.

- Faulty pump – Pumps can fail due to motor issues or debris buildup. If the pump isn’t circulating water properly, it may need to be cleaned or replaced entirely.

- Damaged valves – Valves may become stuck or broken due to corrosion or blockages. Regular inspection and timely replacement can prevent malfunctioning.

- Cracked housing – The outer casing or housing can crack from exposure to extreme temperatures or pressure. A replacement housing will ensure the system’s protection and stability.

Replacing the damaged components promptly will ensure your system operates smoothly, improving water quality and extending the lifespan of the entire filtration setup.