When it comes to maintaining a pool, understanding the inner workings of your pump system is crucial for ensuring smooth operation. A detailed breakdown of the essential components and their functions will help you diagnose issues quickly and make informed decisions about repairs or replacements.

Proper maintenance of each part is vital for extending the life of your pump and optimizing its performance. Familiarizing yourself with the structure and layout of the system allows you to easily identify worn-out or damaged elements, reducing the risk of costly repairs.

By examining each section of the pump, from the motor to the seals, you’ll gain valuable insight into how everything fits together. This knowledge empowers you to tackle maintenance tasks efficiently and avoid potential problems down the line. Whether you’re troubleshooting or performing routine care, understanding your equipment is the first step toward a fully functional system.

Understanding Pool Pump Components

Effective pump operation relies on the proper function of each individual element that makes up the system. From the motor to the mechanical seals, every component plays a crucial role in ensuring optimal flow and efficiency. Understanding how these components interact allows for better maintenance and quicker identification of potential issues.

The motor is the heart of the system, providing the power needed for movement. The impeller is connected to the motor and is responsible for creating the necessary water pressure. Other components, such as the volute and diffuser, help direct the water flow to maintain a consistent operation and prevent blockages or leaks.

Additionally, the filter housing and strainer basket are key parts that ensure debris is removed, keeping the system running smoothly. Over time, these elements may wear out or become clogged, which can affect the pump’s overall performance. By understanding the structure and function of each part, you can improve the longevity of the entire system and prevent unnecessary damage.

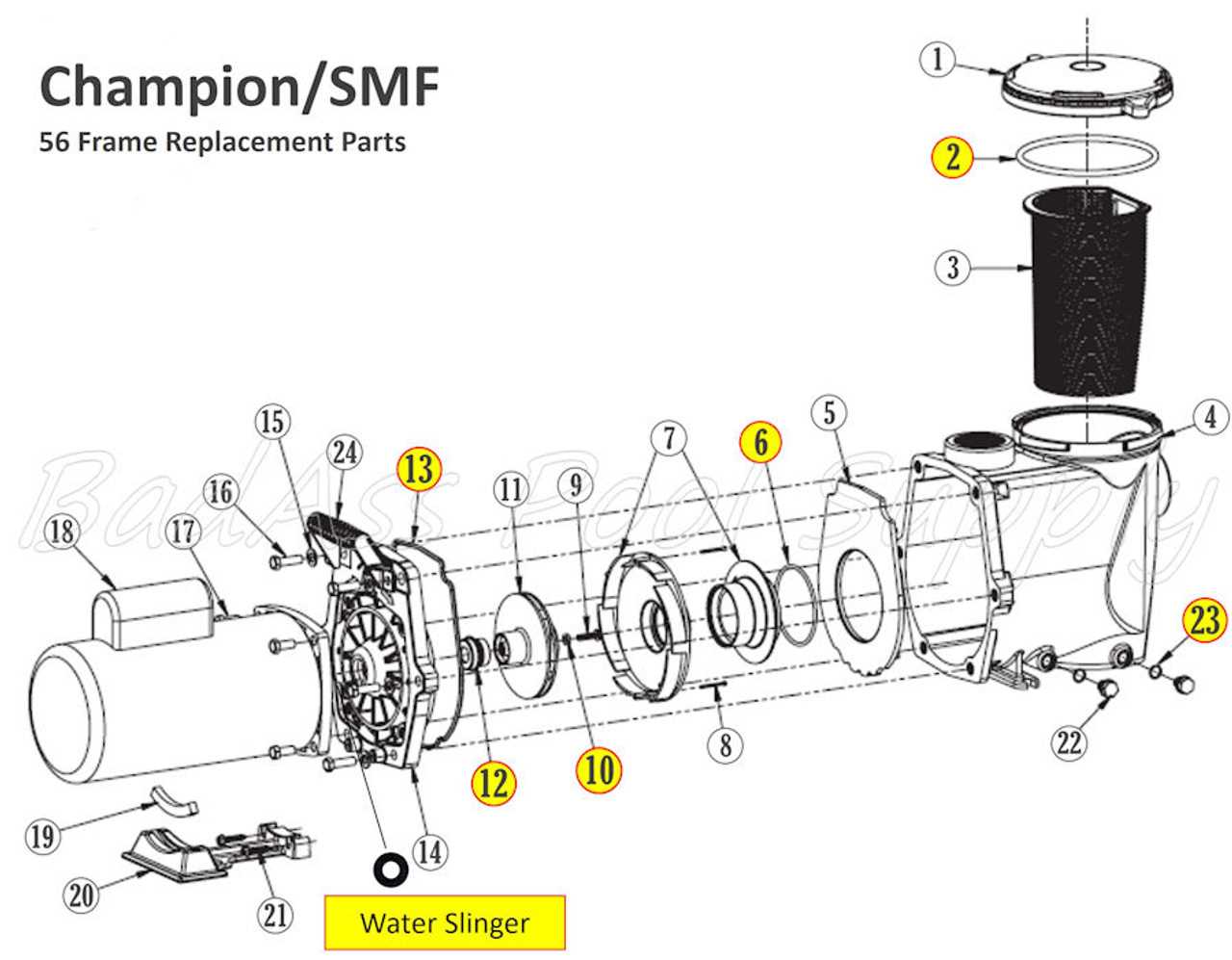

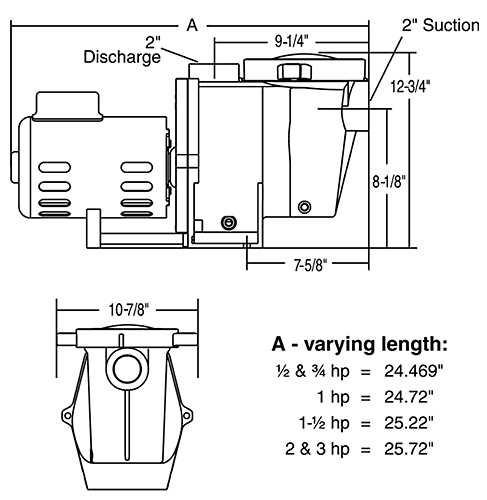

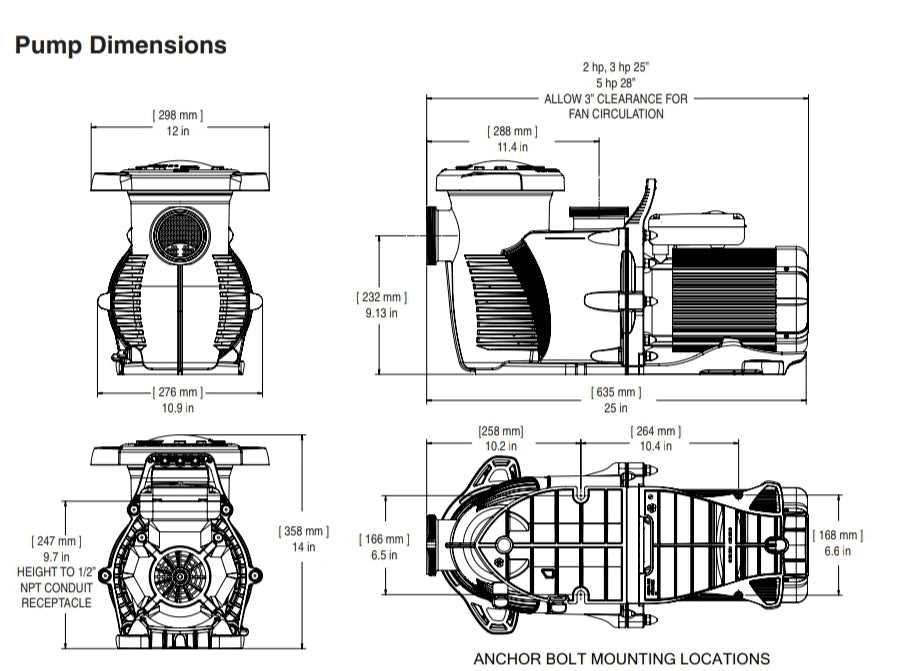

How to Read the Components Layout

Understanding how to interpret a visual layout of your pump’s inner workings is essential for effective troubleshooting and maintenance. These illustrations typically feature labeled parts that correspond to the various components within the system. Each label gives you valuable information about its function and how it fits into the overall mechanism.

Start by identifying the key sections of the system, such as the motor, housing, and intake. Pay attention to arrows and lines that indicate the direction of flow or connections between parts. Detailed labels help you pinpoint specific areas where issues may arise, such as worn-out seals or clogged sections.

Some diagrams will also highlight optional components or upgrades that could enhance the system’s efficiency. Knowing how to read these layouts empowers you to act quickly when maintenance is needed, saving time and reducing the risk of long-term damage. A clear understanding of the components and their roles ensures that you’re always prepared to maintain or repair the system effectively.

Identifying Common Issues with Parts

Recognizing issues with your pump system early on can save both time and money. By understanding the most common problems that arise with individual components, you can address them promptly before they lead to more serious damage. Regular inspections and familiarity with typical signs of wear can significantly improve the longevity of your equipment.

Signs of Wear and Tear

Many components of the system are prone to gradual wear over time. Some common indicators include:

- Leaking seals: Look for water pooling around the pump, indicating a potential seal failure.

- Unusual noise: Grinding or whining sounds may signal problems with the motor or impeller.

- Reduced water flow: A decrease in pressure could point to a clogged filter or damaged components.

- Excessive vibration: This could suggest that the pump is misaligned or that an internal part is loose.

Common Causes of Malfunctions

Understanding the typical causes behind these problems is essential for effective troubleshooting. Some of the most frequent reasons for malfunctions include:

- Debris buildup: Small particles can clog the system, reducing efficiency and causing strain on the motor.

- Overheating: If the pump runs for extended periods without proper maintenance, it can overheat and cause parts to degrade faster.

- Incorrect installation: Improper setup of components can lead to malfunctions, such as poor alignment or blocked water flow.

By staying vigilant and addressing these issues promptly, you can ensure that your pump system operates efficiently for years to come.

Replacing and Maintaining Pump Components

Regular maintenance and timely replacements are key to ensuring the longevity and efficiency of your pump system. By staying proactive in replacing worn-out components and performing essential upkeep, you can prevent major malfunctions and extend the life of your equipment. Understanding the process for replacement and upkeep helps you keep everything running smoothly with minimal downtime.

Steps for Replacing Worn Components

When a component is no longer functioning optimally, it’s crucial to replace it promptly to avoid further damage to the system. The following steps outline how to replace the most common parts:

- Turn off the power: Before working on any part of the system, ensure the power is fully disconnected to prevent accidents.

- Remove the damaged component: Carefully detach the faulty part by loosening any screws or bolts holding it in place.

- Install the new component: Place the replacement part in the same position as the original and secure it tightly.

- Test the system: After installation, run the pump to ensure everything is functioning properly.

Regular Maintenance Tips

Maintaining the system on a regular basis will keep it running at peak efficiency. Some important maintenance tips include:

- Clean filters regularly: Remove debris and clean filters to prevent clogging and maintain optimal water flow.

- Check seals and gaskets: Inspect all seals for cracks or wear and replace them if needed to prevent leaks.

- Lubricate moving parts: Ensure that parts such as the motor and impeller are adequately lubricated to reduce friction and wear.

- Inspect hoses and connections: Look for signs of wear or leaks in hoses and connections to ensure water is flowing properly.

By following these simple steps, you can help ensure the long-term performance of your pump system and avoid costly repairs in the future.

Step-by-Step Guide to Assembly

Assembling your pump system correctly is crucial to ensuring that it operates efficiently and safely. By following a structured approach, you can avoid common mistakes and ensure that all components are properly fitted. This guide provides clear, step-by-step instructions for assembling your pump system from start to finish.

Preparation and Organization

Before starting the assembly, gather all necessary components and tools. Ensure that the workspace is clean and spacious to allow easy access to each part during the process. Here’s what you should do first:

- Check the manual: Refer to the user manual for a complete list of parts and their functions to ensure everything is accounted for.

- Prepare tools: Make sure you have all the required tools, such as wrenches, screwdrivers, and lubrication, ready for use.

- Inspect parts: Check each component for any signs of damage or defects before starting the assembly process.

Assembly Process

Once you’re prepared, follow these steps to assemble the pump system:

- Install the motor: Begin by placing the motor into the designated housing. Secure it firmly with bolts or screws as specified in the manual.

- Attach the impeller: Fit the impeller onto the motor shaft, ensuring it is aligned correctly. Tighten any securing bolts or fasteners.

- Connect the plumbing: Attach the necessary pipes and hoses to the inlet and outlet ports. Use clamps to secure the connections and ensure there are no leaks.

- Install the filter housing: Position the filter housing and ensure it is tightly sealed to avoid water leakage during operation.

- Test the assembly: Once all parts are in place, check the system by running it briefly to ensure everything is functioning correctly and there are no issues.

By following these steps carefully, you can ensure that the pump system is assembled correctly and ready for efficient operation.