Understanding the internal structure of a fishing reel is essential for any enthusiast looking to ensure its longevity and optimal performance. By familiarizing yourself with its key elements, you can troubleshoot issues and perform necessary maintenance with ease.

Disassembling the reel and recognizing each component’s function plays a crucial role in its upkeep. Whether you’re replacing a worn-out part or cleaning the mechanisms, knowing how the different pieces fit together helps in preventing damage and improving overall efficiency.

Regular maintenance can prevent unnecessary repairs, saving both time and money. Identifying potential problems early on will ensure that your gear is ready for your next fishing adventure without any disruptions.

Understanding the Reel Components

Every fishing reel consists of several critical elements that work together to ensure smooth operation. Each piece plays a unique role, contributing to the overall performance of the device. Whether it’s the gearing system, drag mechanism, or spool, understanding the function of each component is vital for proper maintenance and repair.

The internal structure of a reel includes both movable and stationary elements that must interact seamlessly. Recognizing these parts allows users to identify wear and tear, troubleshoot issues, and make necessary adjustments to extend the reel’s lifespan. Familiarizing yourself with the essential features enables better handling and ensures your reel performs at its peak when you need it most.

How to Read the Reel Assembly Guide

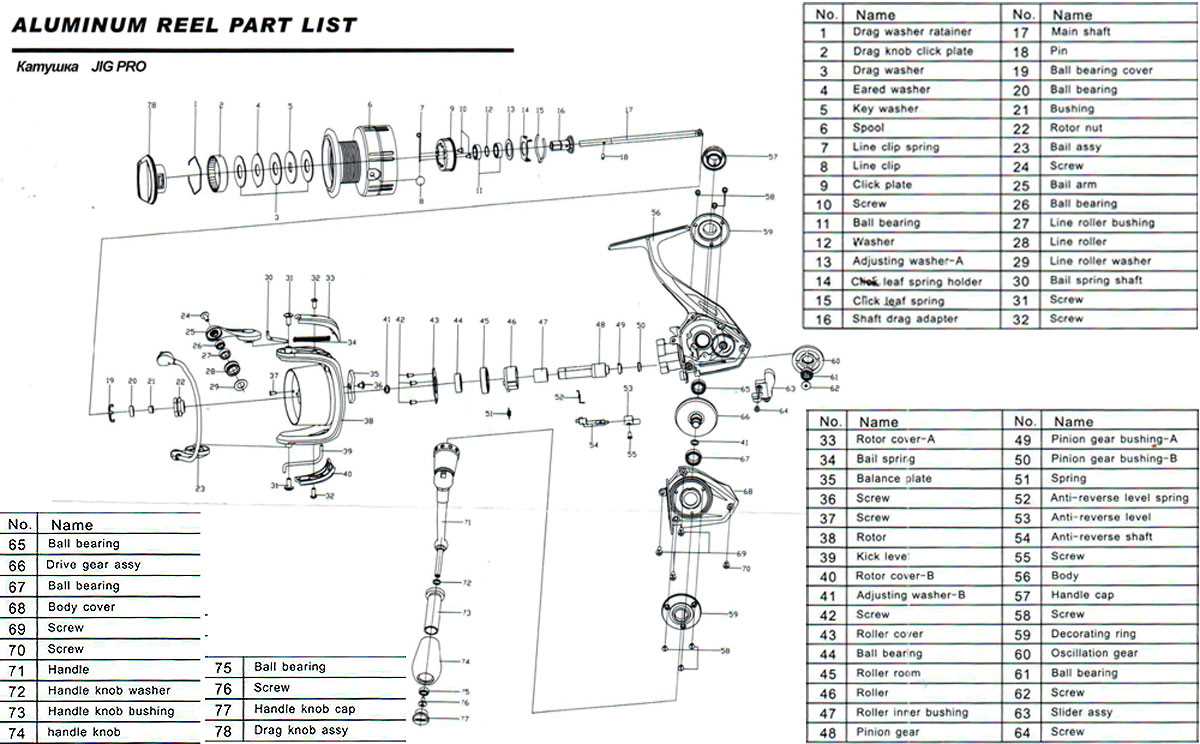

Understanding the visual representation of a reel’s internal components is essential for proper maintenance and troubleshooting. These guides provide a clear map of all the parts, showing how they connect and function together. By following these visual cues, users can effectively identify and address any issues.

To get the most out of this guide, it’s important to:

- Identify the key sections of the guide, such as the main body, spool, and drag system.

- Look for numbered parts or labels that correspond to individual components.

- Understand the relationship between each part and its role within the entire mechanism.

These guides often highlight each part’s specific function, helping users understand how to handle repairs or upgrades. By familiarizing yourself with this visual reference, you can quickly pinpoint what needs attention without unnecessary disassembly.

Common Issues and Repair Solutions

Over time, fishing reels may encounter various problems due to frequent use and exposure to the elements. Recognizing common issues early on can save time and money by allowing for quick fixes and proper maintenance. Here are a few typical concerns and how to address them.

Slipping Drag Mechanism

One common issue is a slipping drag system, where the line may not release properly under pressure. This can occur due to wear in the drag washers or improper adjustment. To solve this, replace the washers if necessary, and ensure that the drag is set correctly for your fishing style.

Difficulty in Spinning or Jamming

If the reel feels stiff or jams during use, dirt or corrosion may have built up in the internal mechanisms. Disassemble the reel, clean all moving parts with a suitable lubricant, and check for any damaged components that need replacing. Proper cleaning can restore smooth operation and prevent further damage.