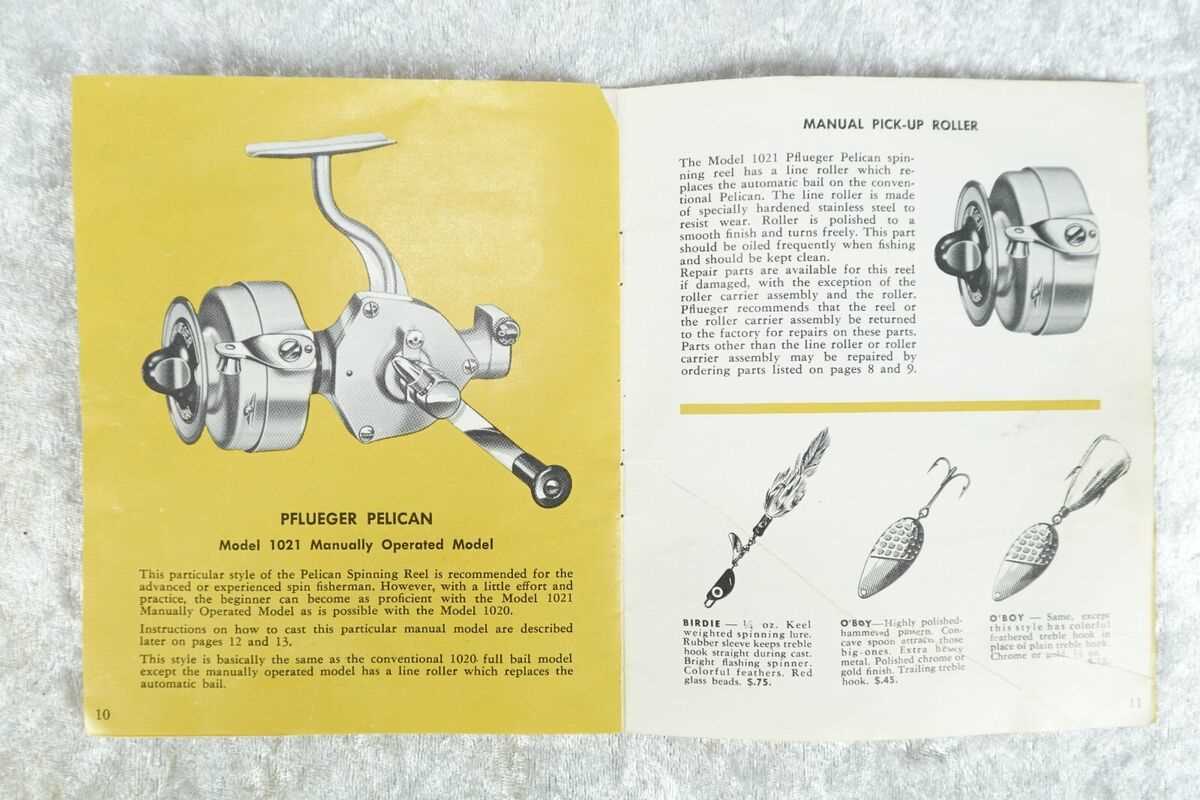

Understanding the intricate design of your fishing equipment is essential for maintaining its performance. Proper knowledge of the different components can make repairs and upgrades simpler and more effective. This guide will help you identify key elements, ensuring your gear stays in top condition for every fishing trip.

Knowing the structure of your equipment is crucial for both quick repairs and preventative care. By familiarizing yourself with each part, you can easily pinpoint issues and address them without unnecessary hassle. This approach not only enhances your fishing experience but also extends the lifespan of your tools.

Mastering the assembly and functionality of your equipment empowers you to make adjustments and fix any malfunctions that arise. A thorough understanding helps you optimize the overall performance and reliability of your fishing tools.

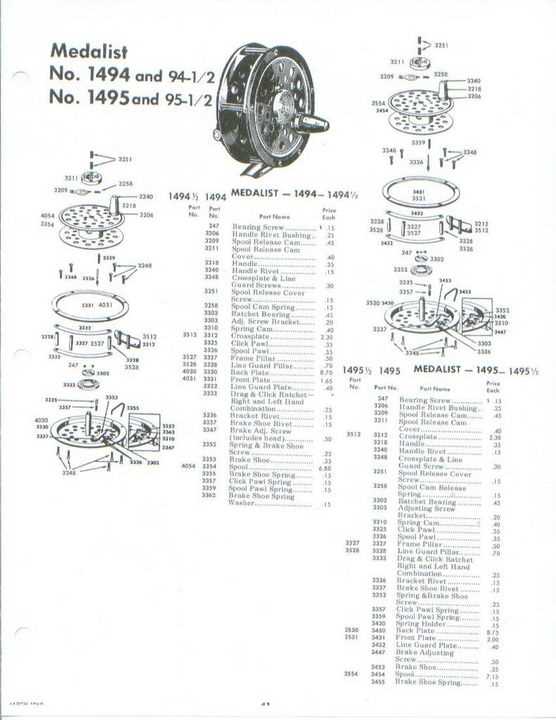

Understanding Fishing Gear Components

Having a clear understanding of the different elements that make up your fishing equipment is vital for proper maintenance and repair. Each component plays a specific role in the overall functionality, and knowing how they work together ensures that everything runs smoothly. This section breaks down the key features to help you identify and maintain your gear effectively.

Key Components of Fishing Equipment

- Spool – Holds the line and is crucial for the smooth release and retrieval of fishing line.

- Drag System – Controls the tension of the line during a fish’s run, preventing breakage.

- Handle – Allows for the manipulation of the system and retrieval of the line.

- Gear Mechanism – Ensures the smooth rotation of the spool and the retrieval of the line at a consistent speed.

- Body and Frame – Provides structure and support for all the components to work together seamlessly.

Importance of Proper Identification

Understanding each component and its function enables you to quickly troubleshoot and repair any issues that may arise. Identifying worn-out or damaged parts allows for timely replacements, which can greatly extend the life of your gear. Familiarizing yourself with the inner workings also helps in making adjustments to improve performance.

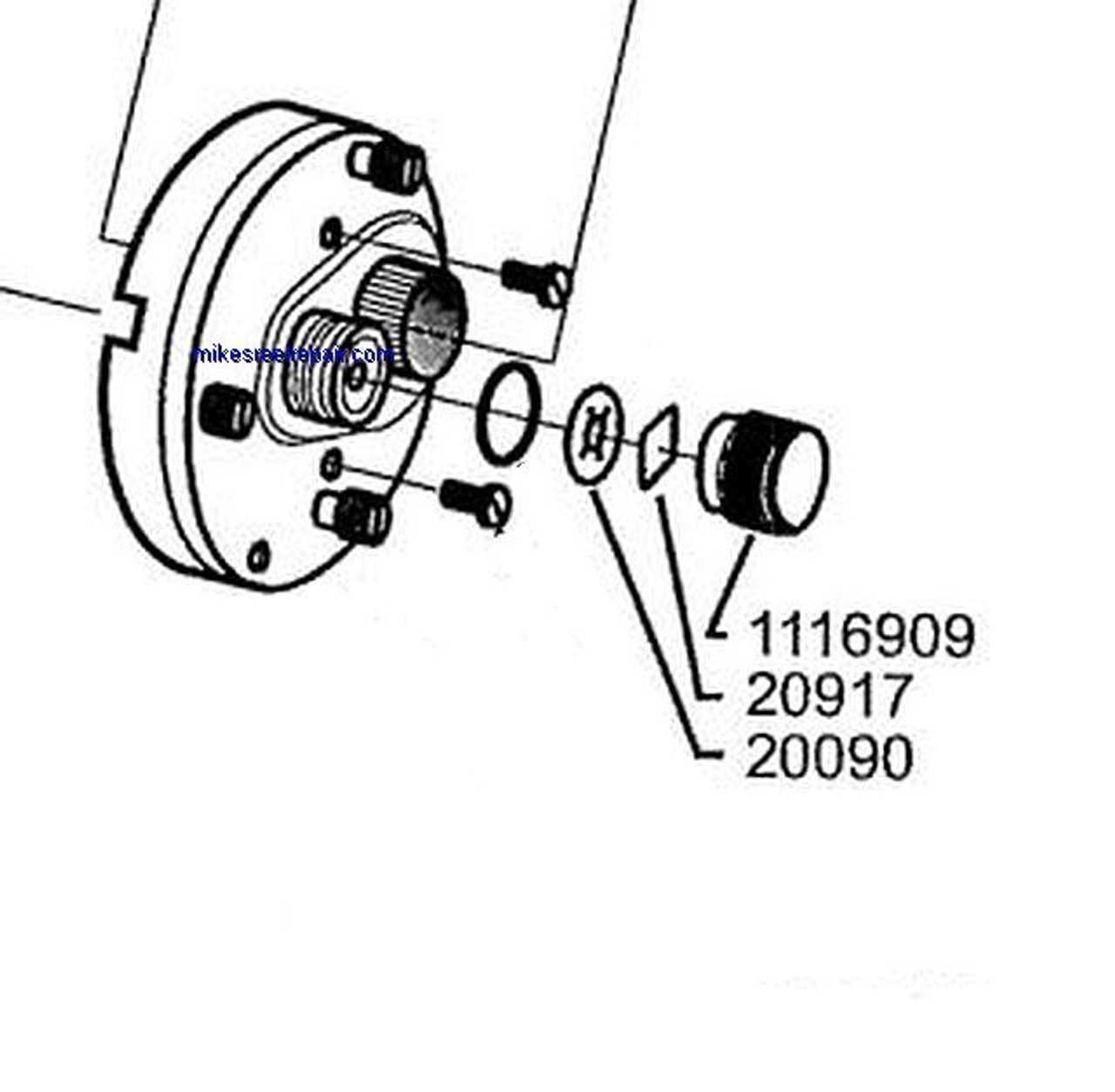

How to Identify Fishing Gear Components

Being able to accurately identify the individual components of your fishing equipment is essential for maintenance and troubleshooting. Each part plays a crucial role in the overall function, and knowing how to distinguish them helps you detect potential issues and address them promptly. This guide explains how to spot and recognize the different elements of your setup.

Visual Inspection Techniques

Start by visually inspecting each element of the equipment. Look for any visible wear or damage that could affect performance. Pay attention to:

- Material Differences – Components may be made from different materials, such as metal, plastic, or rubber, which can help you identify them.

- Shape and Size – Each part typically has a unique shape or size that makes it easy to recognize. For example, the spool is usually round and can vary in diameter.

- Movable vs. Fixed Parts – Components that move, like the handle or drag knob, can be differentiated from stationary elements like the body or frame.

Using the Manual or Reference Guide

For a more precise identification, refer to the manufacturer’s manual or an online guide. These resources often include labeled illustrations and detailed descriptions of each element. Cross-referencing the visual characteristics with the manual helps ensure accuracy in identifying the components of your gear.

Step-by-Step Repair Guide for Fishing Gear

Repairing your fishing equipment doesn’t have to be difficult if you follow a structured approach. By understanding the components and their functions, you can easily identify problems and perform repairs without needing professional assistance. This guide provides a step-by-step process to help you maintain and fix your setup when necessary.

Disassembly and Inspection

Begin by carefully disassembling the gear, making sure to keep track of each component and its position. Take note of any parts that appear worn out or damaged. During the inspection, check for:

- Worn Gears – These can cause improper movement and resistance when retrieving the line.

- Loose Screws – Tighten any loose parts that may affect the stability of the setup.

- Damaged or Frayed Lines – Replace any lines showing signs of wear to prevent future breakage.

Reassembly and Testing

Once the damaged components are replaced or repaired, reassemble the gear carefully. Make sure all screws and parts are tightly secured. Test the functionality by rotating the handle and checking the tension system. If the equipment functions smoothly, the repair is complete. If issues persist, revisit the inspection step to identify any overlooked problems.