Every air compressor is made up of a variety of essential elements that contribute to its overall performance and reliability. Knowing the layout and functionality of these components can make maintenance and repairs much more manageable.

In this section, we will explore the structure of your equipment and explain how each part plays a role in its operation. Whether you’re looking to troubleshoot a malfunction or simply understand your tool better, this guide will provide valuable insights to help you manage your device more effectively.

By familiarizing yourself with the internal system, you can identify problems more quickly and take the right steps to resolve them. Understanding these details can also help extend the life of your equipment.

Understanding Key Components of Your Air Compressor

The functionality of any air compressor relies on a set of essential components that work together to ensure smooth operation. Recognizing the role of each element allows you to diagnose issues, perform maintenance, and improve the overall lifespan of your equipment.

Internal Mechanisms and Their Functions

Each component inside the unit plays a critical role, from the motor to the valves and other internal structures. These parts are designed to handle pressure, airflow, and power distribution, ensuring the device functions optimally during use. Knowing their location and purpose can make troubleshooting more straightforward.

Identifying Wear and Tear

As with any mechanical device, certain components are subject to wear over time. By familiarizing yourself with the specific parts of the compressor, you can detect early signs of damage or malfunction. This proactive approach helps prevent costly repairs and ensures your tool operates efficiently.

How to Identify Key Components in the Diagram

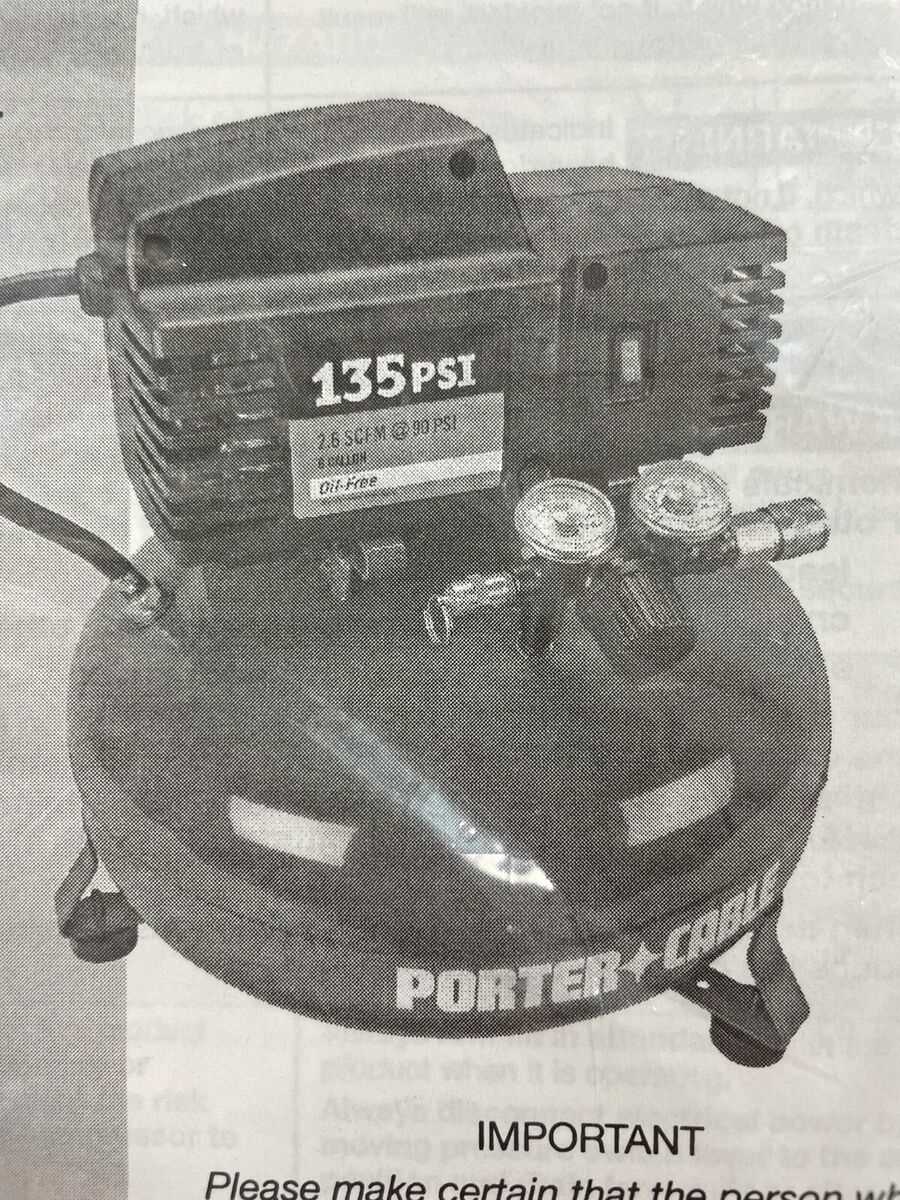

Recognizing the essential elements within a schematic is crucial for maintaining and troubleshooting your air compressor. Understanding where each part is located and how it functions allows for a more efficient repair process and can help prevent unnecessary issues down the line.

Locating Core Elements

The most critical components are typically highlighted and labeled for easy identification. Start by locating the primary sections, such as the motor, valve system, and pressure regulator. Once these are recognized, the rest of the components can be understood in relation to their roles within the system.

Understanding Component Functions

Each part plays a specific function that impacts the overall performance of your equipment. For example, the pressure switch controls the airflow, while the motor powers the compressor. By learning the relationship between these key elements, you can better assess the device’s operation and address any issues that arise.

Step-by-Step Guide to Replacing Components

Replacing worn-out or malfunctioning components is an essential part of maintaining your equipment. By following a structured approach, you can ensure that each part is correctly installed and the system operates as expected after the replacement.

Begin by disconnecting the power supply to ensure your safety during the replacement process. Once the device is powered off, carefully remove any external covers or guards to access the internal components.

Next, identify the specific component that requires replacement, whether it’s the motor, valve, or another part. Take note of its connections and placement within the system, making sure you understand how the new part will fit in. This will help avoid errors during the installation.

After removing the old part, place the new component in the correct position, ensuring it is securely attached and properly aligned. Finally, reassemble the unit, restore the power, and run a test to confirm that the equipment is functioning smoothly.