Understanding the layout of a chainsaw is essential for effective maintenance and repair. Knowing where each part is located and how it interacts with others can save both time and money. This guide provides an overview of the essential components of a typical chainsaw and their roles in ensuring smooth operation.

For anyone involved in repairing or maintaining these machines, recognizing the various components is crucial. Whether you are replacing worn-out elements or simply familiarizing yourself with the setup, this guide will help identify the most important sections of your device.

Learning about each part’s function makes the maintenance process more straightforward. With proper knowledge, even beginners can confidently approach basic repairs or replacements. Familiarity with these elements ensures that the chainsaw operates efficiently and lasts longer.

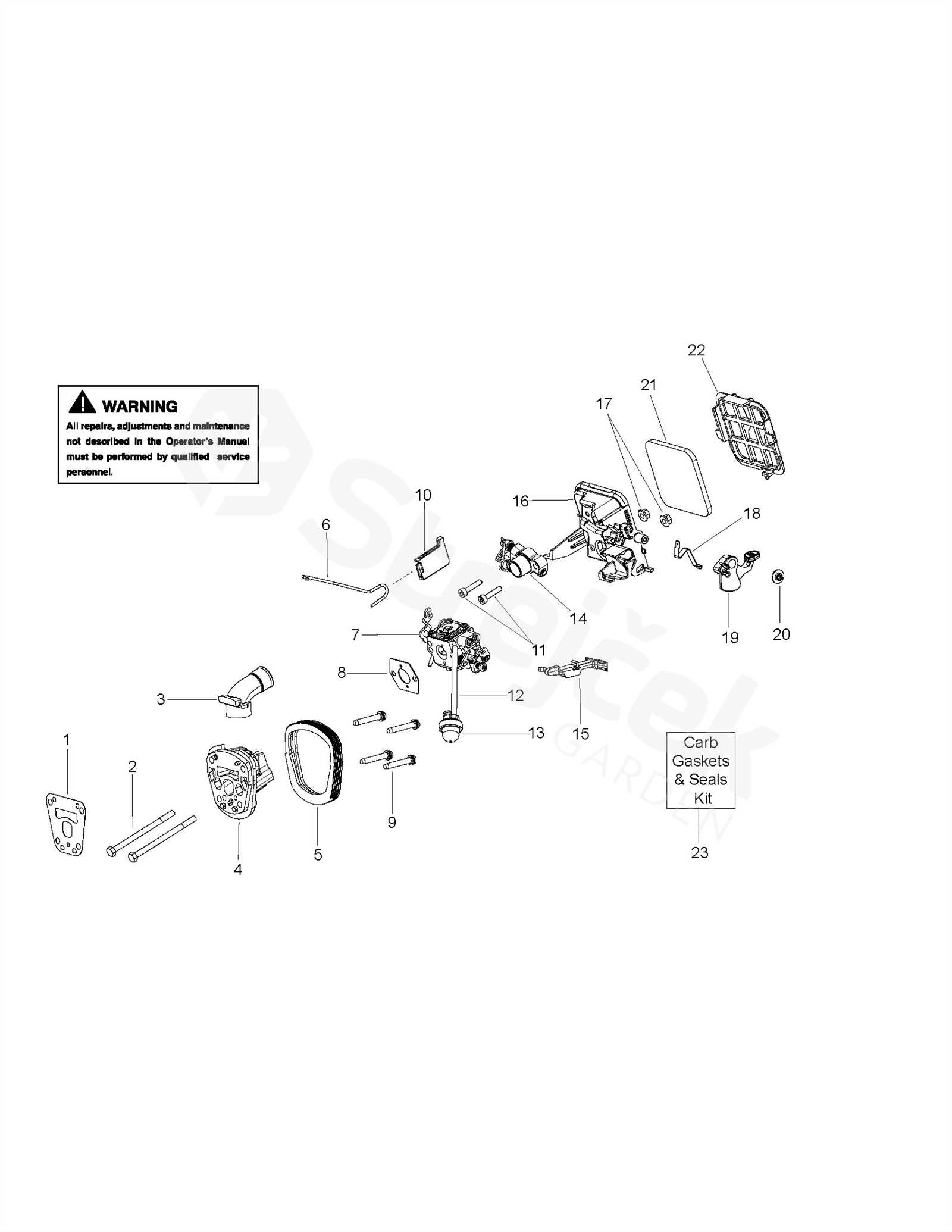

Understanding the Chainsaw Component Layout

To efficiently maintain and repair a chainsaw, it’s crucial to understand the organization of its internal components. This knowledge allows you to pinpoint potential issues, recognize when parts need replacement, and ensure the machine runs smoothly. The layout provides an easy reference to visualize how different elements interact within the device.

Each part plays a specific role, from the engine to the cutting mechanism. Recognizing these roles helps identify what might be causing problems, whether it’s a lack of power, improper function, or wear and tear. A well-structured component layout simplifies the process of disassembling and reassembling the tool.

By familiarizing yourself with this guide, you’ll gain the confidence to perform routine maintenance and necessary repairs. Whether you’re troubleshooting or just looking to understand the tool better, a clear understanding of how everything fits together is key to effective care.

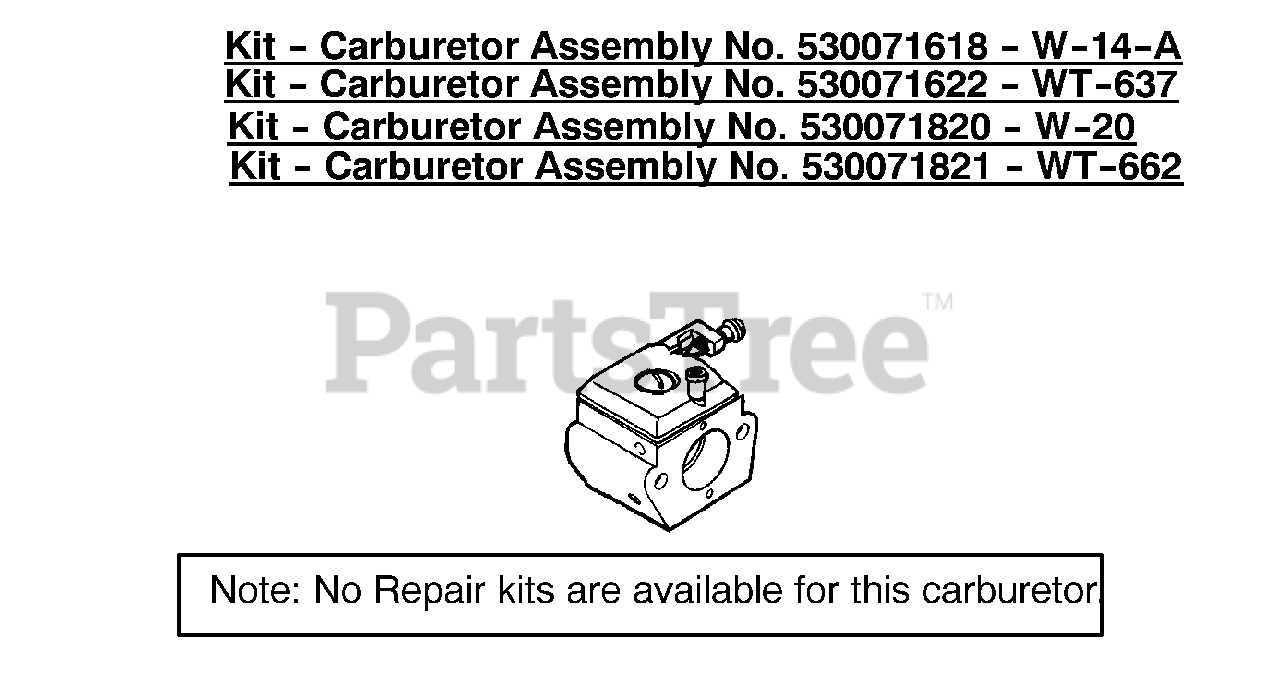

Identifying Key Components for Replacement

Regular maintenance requires knowing which elements of your chainsaw are most likely to wear out and need replacing. Identifying these components early can prevent more serious issues and extend the lifespan of the machine. Some parts are more prone to damage due to frequent use, while others may degrade over time due to exposure to harsh conditions.

The most commonly replaced elements include the chain, bar, and air filter. These parts experience constant stress and are critical for the chainsaw’s performance. Worn-out chains can affect cutting efficiency, while a damaged bar can lead to uneven cuts. Replacing the air filter ensures optimal engine function by allowing proper airflow.

By understanding which components are essential to the tool’s operation, you can prevent unnecessary breakdowns and keep the device in top working condition. Regularly checking these elements and replacing them when needed will help maintain the chainsaw’s performance and reliability.

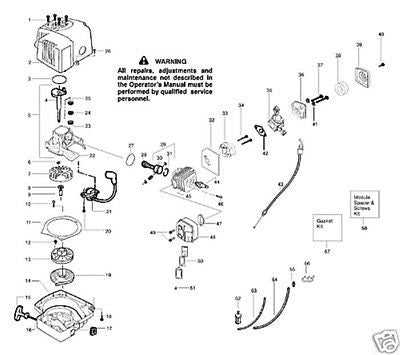

Step-by-Step Guide to Assembly

Assembling your chainsaw correctly is crucial for safe and efficient operation. Following a clear, methodical process ensures that each component is properly fitted and functioning as intended. This guide will walk you through the essential steps to reassemble the machine with precision.

Start by securing the main housing and ensuring all internal components are aligned. Begin with the engine assembly, placing each part in its designated position. This step is vital to prevent misalignment that could cause performance issues later on.

Next, attach the cutting mechanism, ensuring the chain and bar are securely fastened. Make sure the chain is properly tensioned, as incorrect tension can lead to inefficient cutting or damage to the tool. Once the cutting mechanism is set, check the fuel system and air intake to guarantee a smooth flow of fuel and air.

Finally, test the assembly to ensure everything is working correctly. Perform a visual inspection and run the machine briefly to make sure it operates as expected. This thorough process helps avoid any issues that could arise from improper assembly.