Understanding the layout and components of your equipment is key to keeping it running smoothly. A clear representation of the individual parts can greatly simplify the repair and maintenance process, helping you make informed decisions. With a detailed breakdown, users can identify each piece and understand how they fit together, which is essential for proper operation.

Having access to a clear visual reference can save time and effort when dealing with malfunctions. It allows you to quickly spot any faulty parts and replace them, ensuring that your machinery operates at peak efficiency. Whether you’re a novice or experienced, a comprehensive guide to the various components offers valuable support in maintaining your equipment.

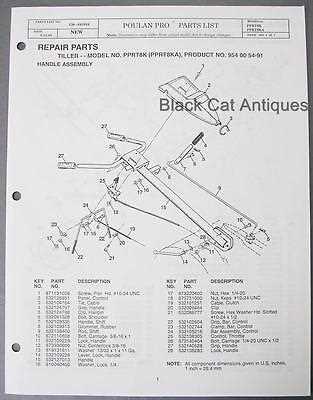

Poulan Pro Parts Overview

Understanding the essential components of your equipment is vital for its upkeep and functionality. Each element plays a crucial role in ensuring smooth operation, and knowing how to identify them allows for efficient repairs and replacements. This section provides an in-depth look at the various elements that make up your machinery, breaking them down into easily recognizable categories.

Key Components for Smooth Operation

Every piece of equipment contains a variety of key elements that work together to perform specific tasks. These include the engine, fuel system, and moving parts that require proper maintenance. Understanding the function of each component helps you identify potential issues and ensures you know where to focus your attention during regular checkups.

Common Maintenance and Repair Needs

Regular maintenance of each part is crucial for longevity. Common repairs often involve checking and replacing worn-out components such as belts, filters, and spark plugs. Being familiar with these parts and their specific functions allows for quicker fixes and minimizes downtime, keeping your machinery in top condition.

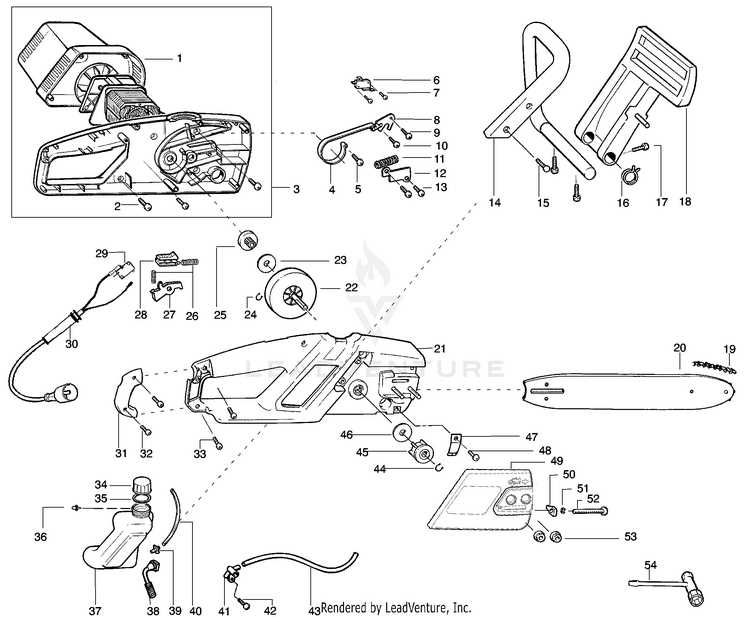

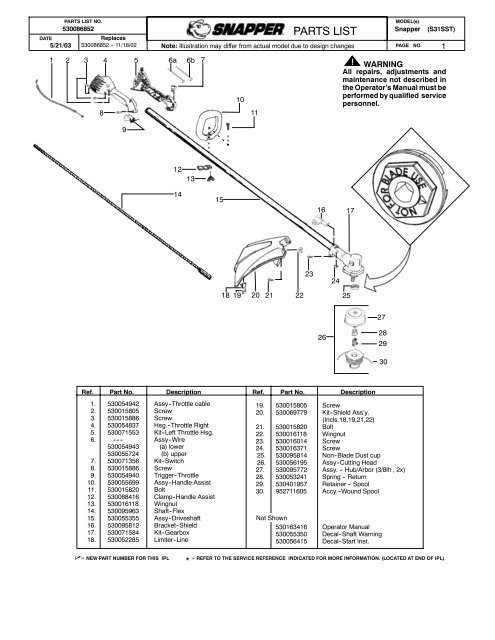

Understanding the Parts Diagram

Gaining a comprehensive understanding of the individual components within your machinery is essential for proper maintenance and troubleshooting. Visual representations can help you identify where each element fits and how it interacts with the others. This section explains how to navigate these diagrams, allowing for easier identification of specific components and their functions.

How to Read the Visual Guide

Each illustration offers a clear overview of your equipment, showing the layout of all key elements. With labels and detailed markings, these guides allow you to pinpoint specific components, their placement, and their role within the system. Understanding these visuals makes it easier to locate issues and determine which parts need attention or replacement.

Using the Visuals for Efficient Repairs

When faced with a malfunction, referring to these diagrams speeds up the repair process. By identifying the parts that are damaged or worn, you can take immediate action and source the right replacements. This structured approach reduces mistakes and ensures your machine continues to function optimally.

How to Use the Diagram for Repairs

Using a detailed visual representation can significantly improve the repair process by providing clear guidance on component placement and functions. These guides allow you to quickly identify which parts need attention, helping you make informed decisions during repairs. By following the illustrations step by step, you can avoid errors and ensure the correct part is addressed.

To start, locate the specific section of the guide that corresponds to the area you’re working on. The labels will direct you to the individual components, making it easier to spot any issues. Once you identify the problematic part, you can confidently proceed with its replacement or adjustment, ensuring minimal disruption to your equipment’s operation.