When it comes to maintaining and repairing your outdoor machinery, knowing how each part functions is essential. Understanding the structure of your equipment can save time, reduce costs, and ensure that your machine operates at its best. This guide will help you identify various components, making it easier to troubleshoot or replace them when necessary.

Identifying individual pieces can seem overwhelming, but once you’re familiar with the layout and role of each section, the process becomes more intuitive. Whether you’re preparing for a simple repair or conducting regular maintenance, having a clear understanding of the components is key to successful operation.

Regular inspection is often the first step to preventing major issues. By recognizing common wear and tear, you can address small problems before they become costly repairs. This approach leads to a longer lifespan and optimal performance of your machine.

Understanding Outdoor Equipment Components

Maintaining outdoor machinery effectively requires an in-depth understanding of its various components. Each section of the machine plays a vital role in ensuring smooth operation. From the engine to the smaller moving parts, recognizing how these elements interact can prevent unnecessary damage and reduce downtime during repairs.

Key Functional Elements

The core function of any equipment relies heavily on its key functional elements. These are typically the most robust and complex parts that require regular inspection and care. Ensuring their proper functioning not only extends the life of the machine but also improves efficiency during usage. Regular checks on these components will help detect any wear and tear that might affect performance.

Minor Components and Their Role

While the main parts are crucial, the smaller components also serve a significant purpose. These often-overlooked elements, such as fasteners, belts, and connectors, contribute to the overall effectiveness and safety of the equipment. Understanding their role and ensuring they remain intact is just as important as maintaining the major parts.

How to Identify Outdoor Equipment Components

Recognizing the various elements of your outdoor machinery is essential for proper maintenance and troubleshooting. By familiarizing yourself with each component, you can more easily spot issues that may arise, and better understand the role of each part in ensuring smooth operation. Knowing the structure of your machine not only helps during repairs but also improves overall functionality and longevity.

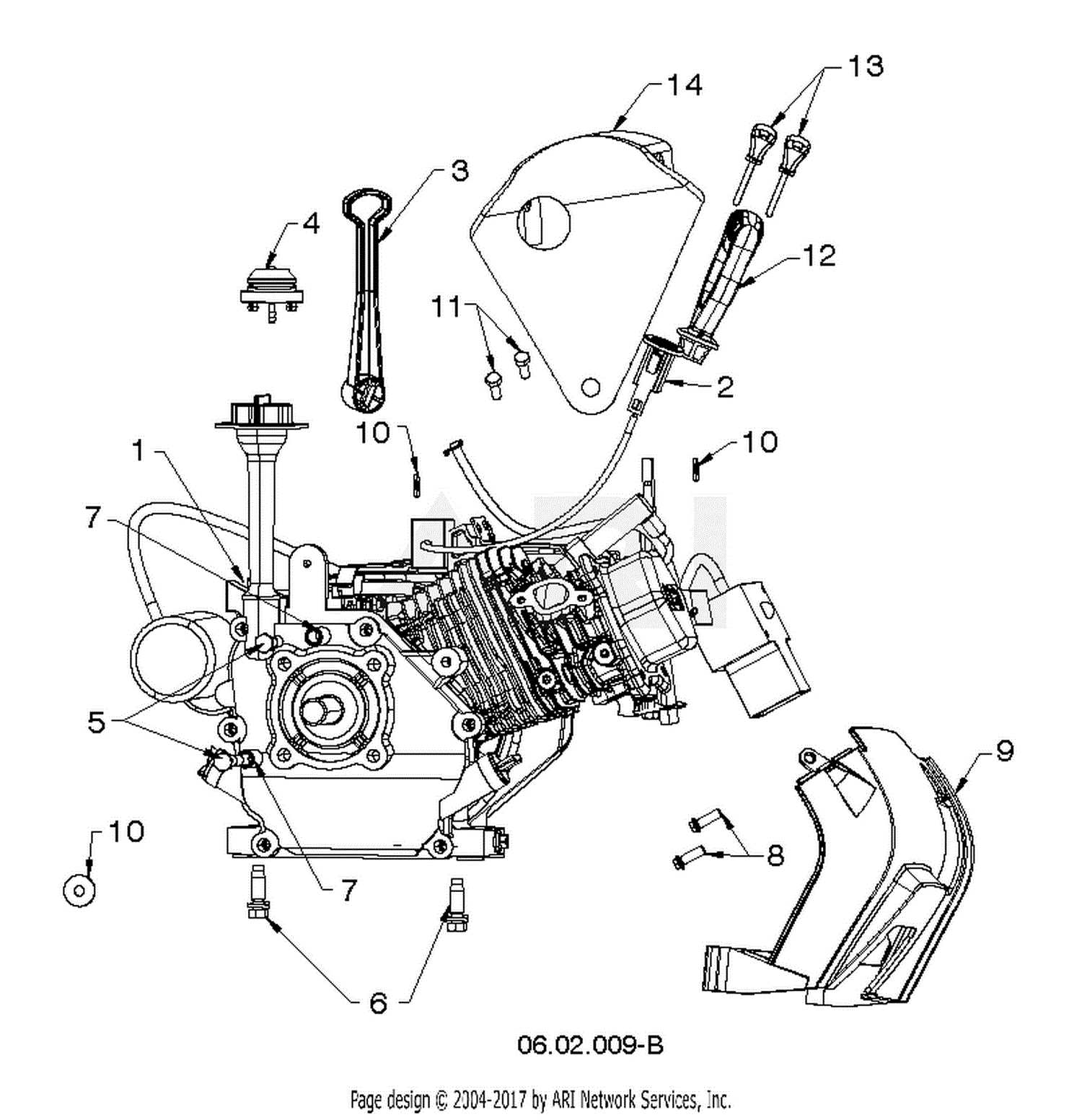

Inspecting Major Sections

The first step in identifying components is to focus on the larger, more prominent sections of the equipment. These include the engine, control mechanisms, and power sources. They are often easier to spot and play a central role in the overall functioning of the machine. Understanding their purpose and how they interact is key to diagnosing issues effectively.

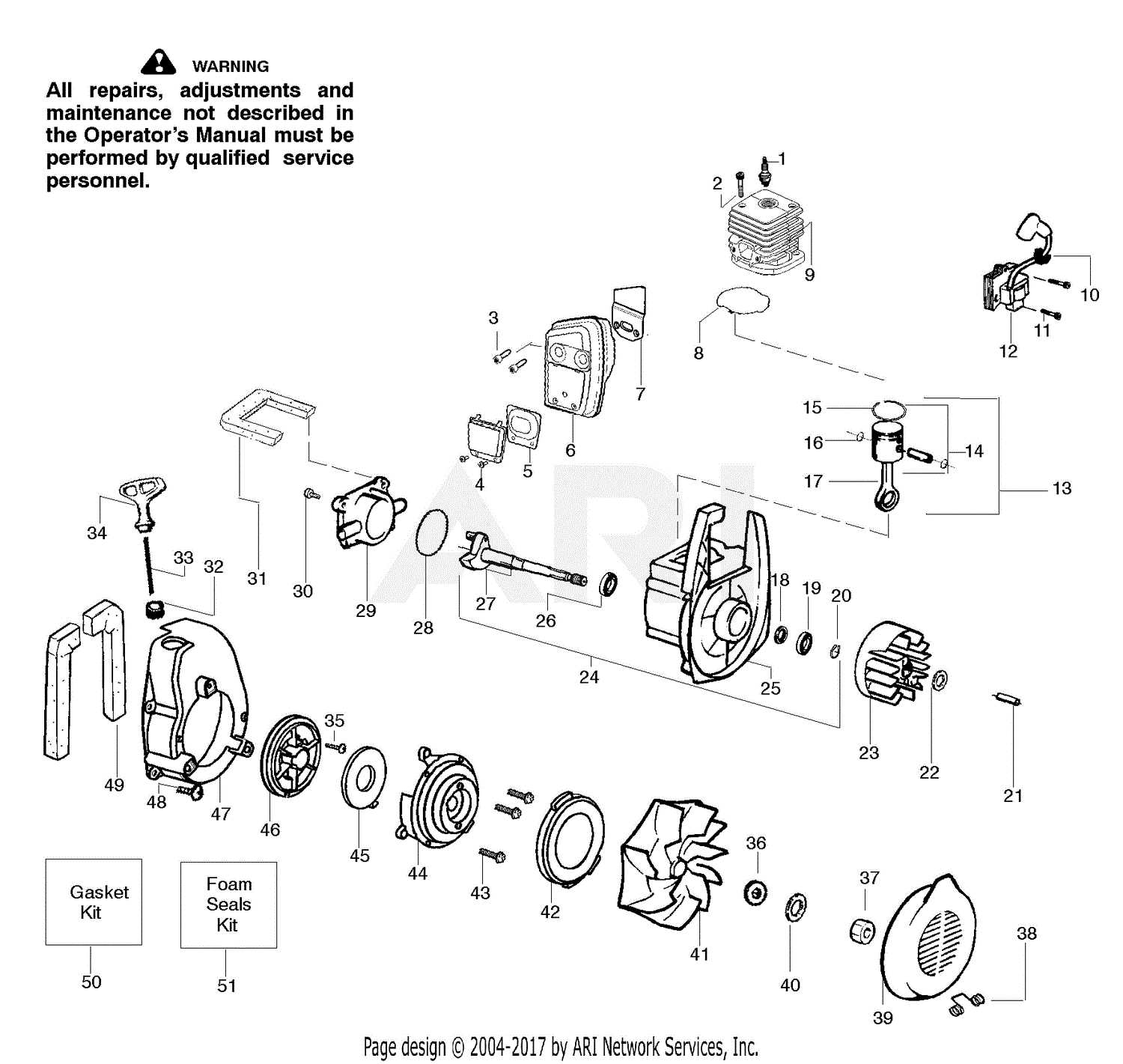

Understanding Smaller Elements

Smaller components, such as belts, switches, and connectors, may not be as visible but are crucial to the operation of the machinery. Take time to familiarize yourself with these minor parts. Often, their failure can lead to significant disruptions, so recognizing early signs of wear can help prevent costly repairs down the line.

Common Issues with Outdoor Equipment Components

Every machine experiences issues from time to time, and understanding the most common problems with its components can help prevent unnecessary repairs. Many of these issues are related to wear and tear, incorrect usage, or lack of proper maintenance. Identifying these issues early ensures that your machine continues to run efficiently and safely.

One of the most frequent problems is the deterioration of belts and connectors. These elements often face heavy stress and, over time, can become loose, cracked, or worn out. Regular inspections and prompt replacements of these smaller components can prevent more serious malfunctions.

Another common issue is related to the engine and its fuel system. If the machine is not running smoothly, it could be due to clogged filters, old fuel, or worn-out spark plugs. Keeping the engine clean and regularly replacing these critical parts ensures that the equipment performs at its best.