When working with complex machinery, having a clear view of its individual components is essential for efficient repair and maintenance. Knowing where each element fits and how it interacts with others can significantly reduce troubleshooting time. This section will help you identify key elements of the system, ensuring you’re equipped with the right information for any task.

Each part plays a vital role in the overall functioning of the device. By understanding how the system is structured, you can approach repairs with confidence and precision. From basic maintenance to intricate replacements, knowing the layout of every section is crucial for long-term reliability.

Having a clear guide to reference will save you time and effort. This breakdown offers practical insights into identifying and locating each part quickly, allowing you to focus on what really matters: restoring optimal performance.

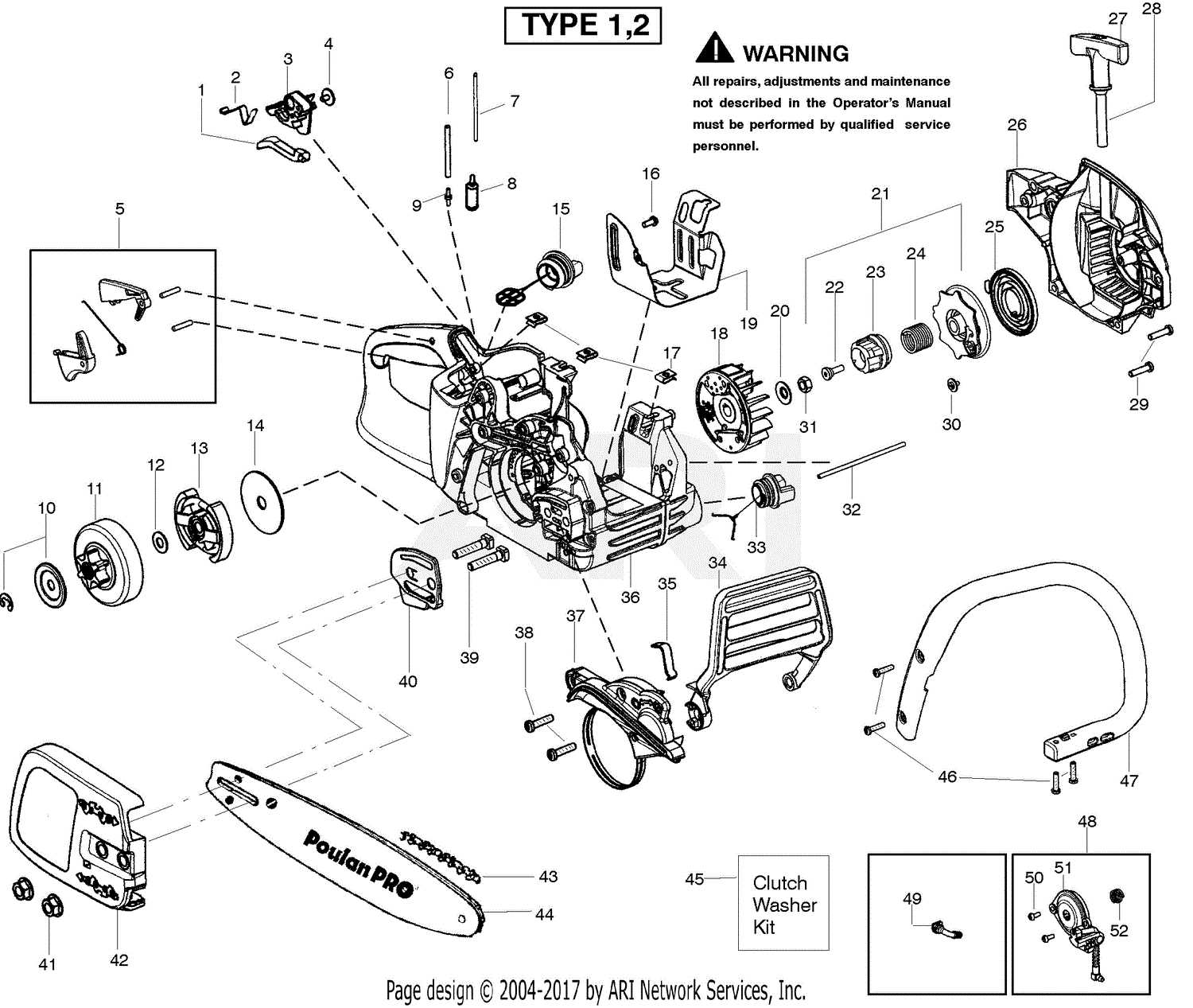

Understanding PP4218A Parts Layout

In any mechanical system, the arrangement and relationship between individual components are key to understanding its functionality. A well-organized structure allows for easier identification and maintenance of each element. Knowing how each section is positioned within the overall assembly helps ensure efficient troubleshooting and repairs.

By mapping out the various components, you can see how they connect and interact with one another. This not only aids in diagnosing issues but also provides valuable insights into the system’s design, making it simpler to work with. The clarity of this layout supports technicians in performing tasks with precision, whether it’s performing regular checks or replacing worn-out components.

Familiarity with the arrangement can drastically reduce the time needed for maintenance and repairs. A comprehensive understanding of the layout makes it easier to identify potential problems early, leading to faster solutions and minimizing downtime. Ultimately, this knowledge empowers anyone working with the system to operate it more effectively and with confidence.

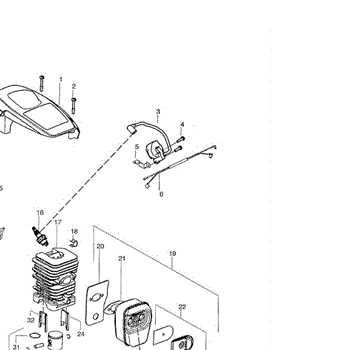

How to Read PP4218A Diagram

Understanding how to interpret technical layouts is crucial for anyone working with complex machinery. These illustrations provide a detailed representation of the system’s components, highlighting how each element is connected. By learning to read these visual guides, you can quickly identify the location and function of each part, making maintenance tasks more manageable.

Identifying Key Symbols and Labels

Most schematics use standardized symbols to represent different parts, making it easier to understand the layout at a glance. These symbols are often accompanied by labels indicating the part number or function. It’s important to familiarize yourself with these symbols to navigate the diagram effectively and ensure accurate identification.

Understanding the Flow and Connections

The layout will often show how components are linked together, either through physical connections or operational flow. Pay attention to lines and arrows that indicate relationships between different elements. By following these pathways, you can trace the system’s structure and spot any areas that may require attention during repairs.

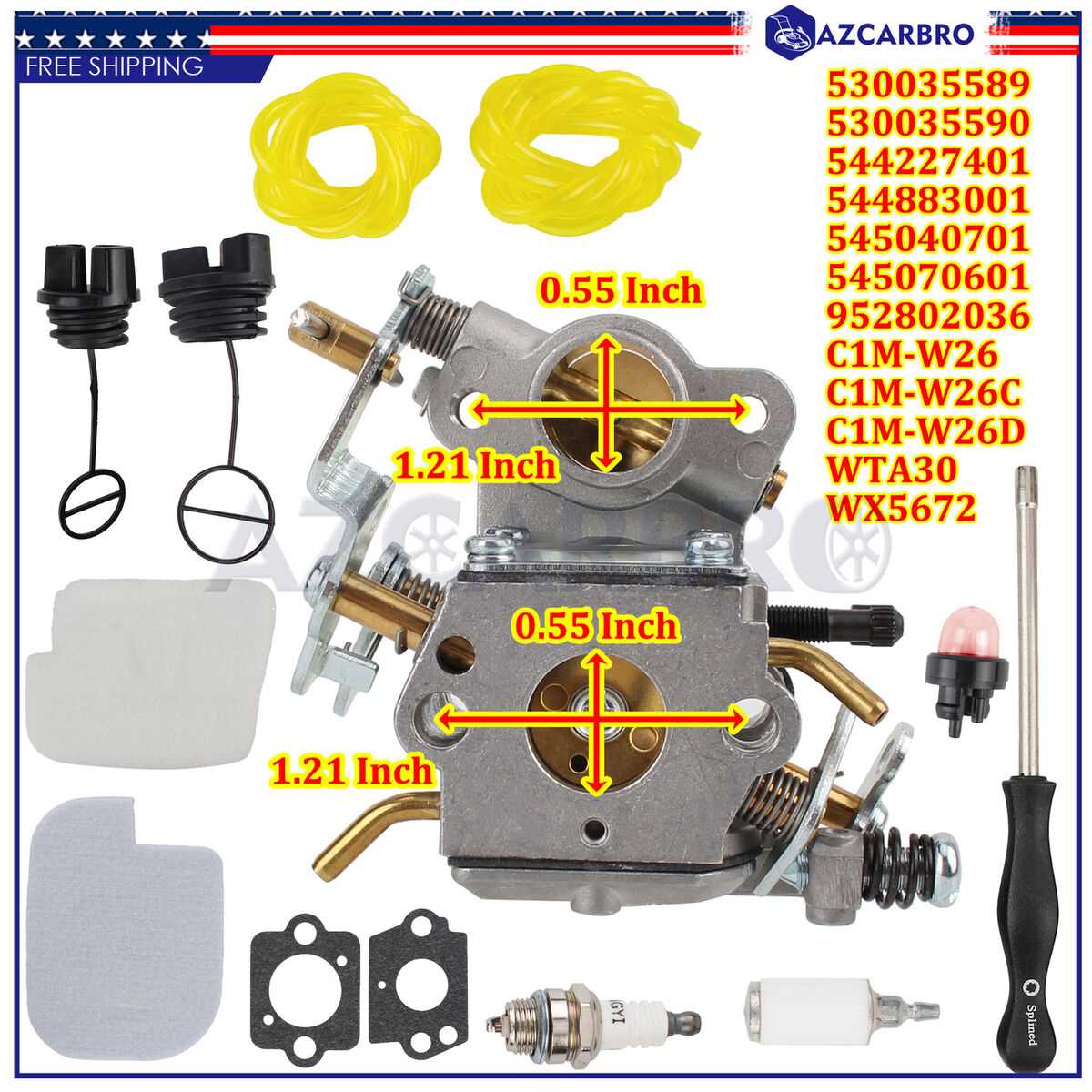

Key Components of PP4218A System

Every system is made up of distinct elements, each playing a specific role in ensuring its efficient operation. Understanding these core components is essential for effective troubleshooting and maintenance. By identifying the main features and their functions, you can more easily diagnose issues and perform repairs with confidence.

Core Functional Units

The central units of the system are responsible for its primary operations. These components manage the most critical tasks, such as power distribution or data processing, depending on the system’s nature. Recognizing these essential parts helps streamline maintenance and ensures that the system functions optimally over time.

Supporting Elements and Accessories

In addition to the core units, there are supporting elements that enhance the overall performance. These components include connectors, safety devices, and auxiliary systems, which provide stability and improve the system’s overall efficiency. Even though these parts may seem secondary, they are integral in ensuring smooth operation and preventing failures.