When it comes to maintaining any mechanical device, having a clear understanding of its components is essential for effective troubleshooting and upkeep. Knowing how different parts interact allows you to identify potential problems early and address them efficiently. Whether you’re a seasoned technician or a first-time user, this knowledge can save you time and money on repairs.

In this guide, we’ll explore the essential components of your equipment and provide a detailed view of how each element functions within the system. By breaking down the structure and function of each part, we aim to make maintenance tasks more manageable and help you make informed decisions when it comes to repairs.

Being proactive with care and understanding of your device’s mechanics ensures a longer lifespan and optimal performance. Whether you’re preparing for routine servicing or facing a specific malfunction, this resource will be your go-to reference for all the key information.

Understanding the Predator 2000 Generator Components

Every mechanical device consists of numerous elements, each with a specific role in ensuring smooth operation. By understanding the function of these individual components, users can perform better maintenance and spot issues before they become serious problems. In this section, we’ll dive into the different internal mechanisms, highlighting their purpose and how they contribute to the overall performance of your equipment.

Core Functions of the Major Components

At the heart of the system are a few crucial elements that manage the device’s power production and distribution. These include the engine, the fuel system, and the electrical output assembly. Each part works in tandem to provide consistent and reliable performance, and understanding their relationship is key to identifying potential failure points. Regular checks on these components can ensure efficiency and longevity.

Maintaining Optimal Performance

In addition to the core components, various supporting mechanisms like the cooling and exhaust systems play vital roles in preventing overheating and maintaining airflow. These systems are equally important for overall efficiency, and neglecting them can lead to issues like overheating or premature wear. Proper inspection and care of all components are essential for keeping your machine running smoothly over time.

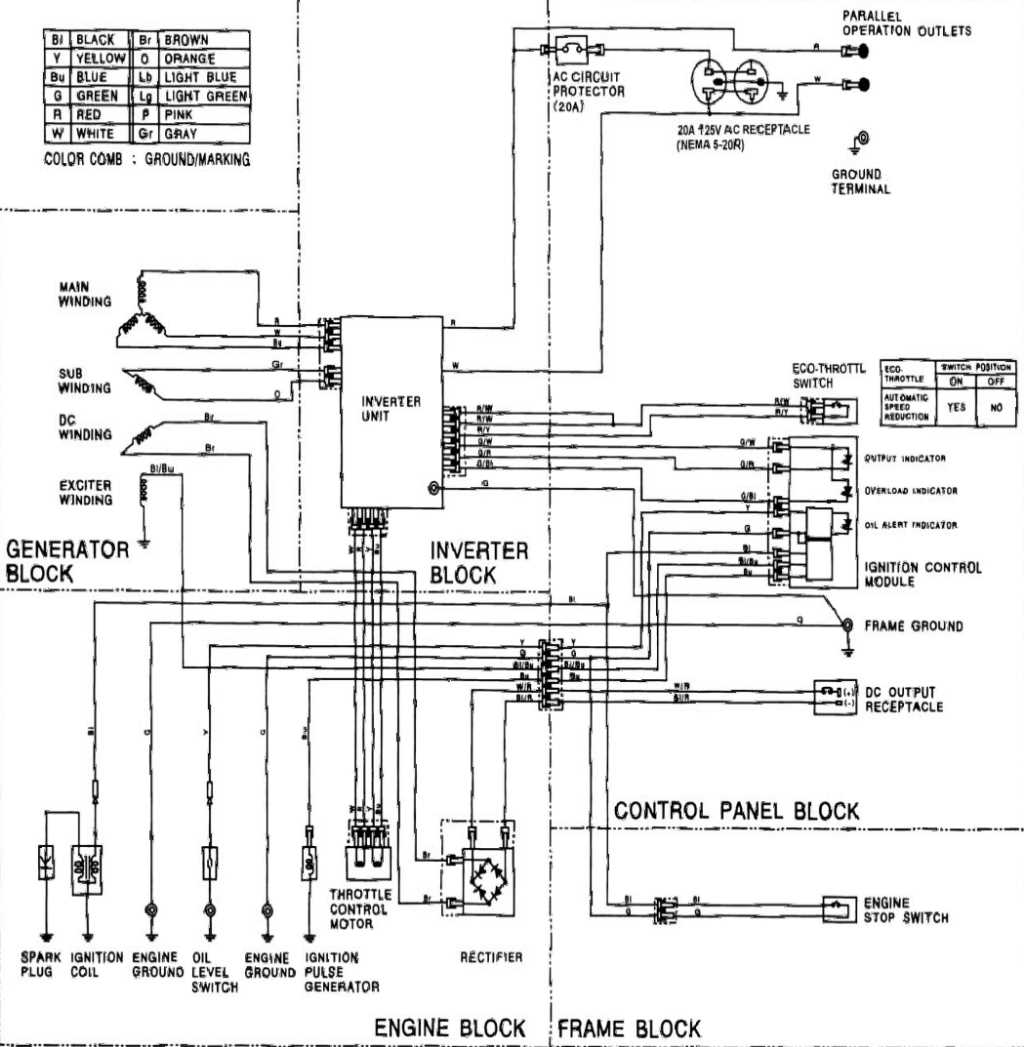

How to Identify Parts in the Diagram

Understanding how to navigate a system’s internal layout is essential for effective maintenance. By recognizing each component’s location and role, you can quickly identify issues and perform accurate repairs. This section will guide you through the process of interpreting a schematic representation of the device, ensuring you can efficiently find and address any malfunctioning elements.

Reading the Schematic Representation

The first step is to familiarize yourself with the overall layout of the system. Each part is represented by a symbol or label that corresponds to a specific function within the machine. Once you know the general structure, understanding the flow of energy and how different sections connect becomes easier. Focus on key elements such as the power source, control systems, and connectors, as they are often the most vital components to monitor.

Locating Components and Connections

Next, pay attention to the detailed labels and arrows on the schematic. These indicate how parts are connected and their orientation within the overall structure. For example, identifying the fuel lines, airflow direction, and electrical terminals can help you understand how energy and resources move through the machine, allowing you to troubleshoot more effectively. By cross-referencing these symbols with your equipment, you can quickly pinpoint the issue area and take action.

Common Issues and Troubleshooting Tips

Even the most reliable equipment can experience problems over time. By recognizing common malfunctions and understanding how to address them, you can prevent major breakdowns and extend the life of your device. This section will highlight frequent issues users encounter and provide helpful solutions to get your system running smoothly again.

Frequent Problems and Their Causes

One of the most common issues users face is difficulty starting the machine. This could be caused by a number of factors, such as an empty fuel tank, clogged fuel lines, or a dead battery. Inspecting the power source and fuel system is the first step in troubleshooting this issue. Another frequent problem is overheating, often resulting from blocked air vents or a malfunctioning cooling system. Regularly cleaning the intake and exhaust areas can help mitigate this.

Effective Troubleshooting Methods

Once you identify the source of the problem, it’s important to act quickly. For electrical issues, check the wiring and connectors for signs of wear or corrosion. Re-tightening connections or replacing damaged cables can restore proper function. For mechanical faults, such as a noisy engine or reduced performance, check for loose components or worn-out parts. Taking a systematic approach to diagnosis ensures that you don’t overlook minor issues that could lead to bigger problems down the line.