To fully comprehend how a device operates, it’s essential to break down its key elements and their roles within the system. Each component plays a vital part in ensuring smooth functionality, and recognizing them can significantly enhance troubleshooting and maintenance skills. In this section, we explore the individual components that make up the structure of such equipment.

Familiarizing yourself with the layout of internal mechanisms allows for a better understanding of the device’s performance. Whether you’re looking to fix a malfunction or improve efficiency, knowing what each part does and how it interacts with others is crucial. The complexity of these systems can often be overwhelming, but with the right knowledge, it becomes much easier to identify potential issues.

In the following sections, we will discuss the essential building blocks, their connections, and how they contribute to the overall operation. A deeper insight into the arrangement and functionality of these elements helps ensure effective use and care of the equipment.

Key Components of a Printer

In any printing device, a variety of internal elements work together to ensure accurate and efficient output. These components each serve a distinct function, and understanding their roles can help with both optimization and troubleshooting. The interaction between mechanical, electrical, and software systems forms the foundation of the device’s overall performance.

One crucial element is the feed mechanism, responsible for guiding the material through the system. This ensures that the sheet or roll of media is precisely positioned for accurate transfer of the print. Coupled with this, the toner or ink system plays an essential role in transferring marks onto the surface, enabling clear and consistent results.

The control unit is another vital part, processing the information and executing commands from the software. It directs the actions of the various components, ensuring proper synchronization. Other elements such as the power supply and sensor systems also play significant roles in maintaining smooth operation and preventing malfunctions.

Understanding Printer Mechanisms and Functions

Efficient output relies on a series of interconnected processes that transform digital data into tangible results. The internal systems of such a device work seamlessly together, each element performing a specific task to ensure smooth operation. By grasping the core functions of these mechanisms, users can gain a better understanding of how the entire system achieves its intended purpose.

One fundamental process is the movement system, responsible for guiding media through the device. This system coordinates with the imaging mechanism, which applies the necessary markings to the surface. Synchronizing these actions ensures that each page or sheet is processed in the correct manner, avoiding issues like misalignment or incomplete transfers.

The control system acts as the brain, interpreting commands from external sources and directing the operation of other components. This mechanism not only processes input but also manages the flow of power, temperature, and pressure, maintaining consistency throughout the entire procedure. When all systems function in harmony, the results are precise and reliable.

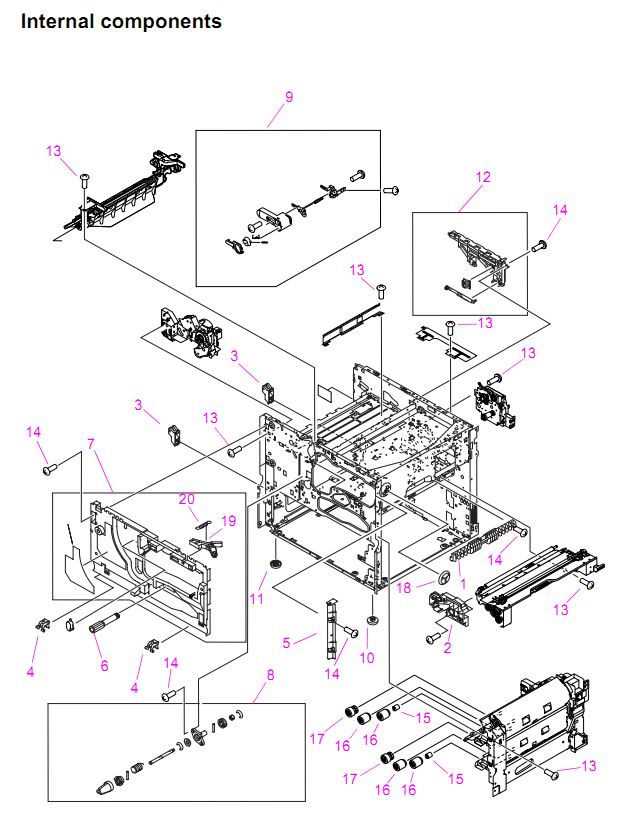

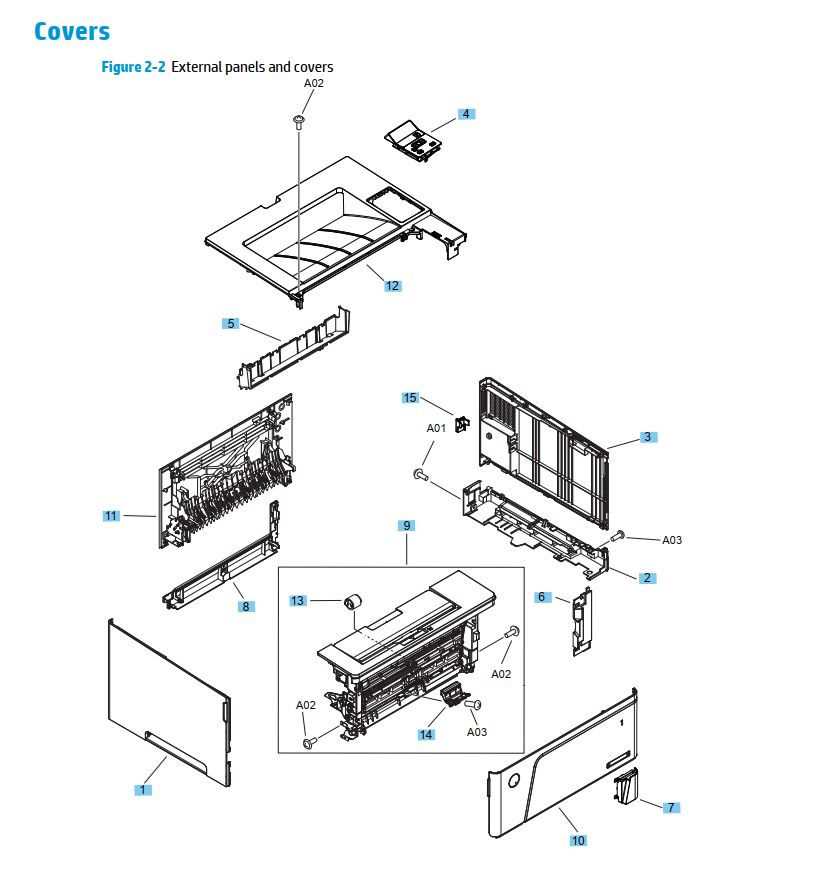

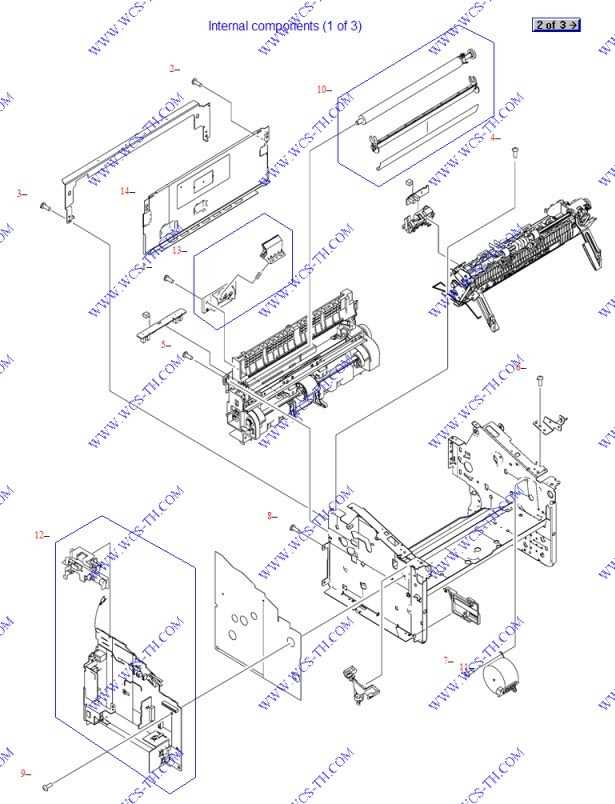

How to Identify Parts in Printer Diagrams

To fully understand how a device functions, it’s essential to recognize its key elements and their specific roles. When reviewing visual representations of the internal structure, it’s important to know how to identify each component and its relationship to the overall system. This understanding allows for better troubleshooting, maintenance, and optimization.

One of the first steps is recognizing the labels and symbols that indicate each component. These visual cues provide an overview of the system’s layout, making it easier to pinpoint individual elements. Pay close attention to the connections between these components, as they highlight the flow of power, data, or mechanical actions within the system.

Once the basic structure is understood, it’s helpful to focus on the functionality of each part. By comparing the shapes, sizes, and locations of components with their roles, you can quickly discern their purpose. This approach enhances your ability to interpret the layout and effectively diagnose any issues that may arise during operation.