Knowing the structure of your crossbow is essential for effective use and maintenance. A clear understanding of its individual elements allows for proper care, troubleshooting, and customization. Whether you’re assembling or repairing your gear, familiarity with the key components ensures the longevity and reliability of your equipment.

Detailed visuals and clear explanations help you identify each part and its function. By having a comprehensive overview, you can quickly locate any potential issues and address them with ease. Proper maintenance not only boosts performance but also improves safety, ensuring a smooth shooting experience.

Familiarity with the mechanics also opens the door to better customization options, allowing you to fine-tune your gear to your specific needs. With the right knowledge, you can enhance the precision and power of your equipment, taking your skills to the next level.

Understanding the Ravin R20 Crossbow Components

Every crossbow consists of several essential elements that work in unison to ensure optimal performance. Familiarizing yourself with these individual components is crucial for both maintenance and effective use. Each piece plays a unique role, and understanding how they function together can help you troubleshoot issues and enhance your shooting experience.

Key Elements of a Crossbow

The main components of any crossbow include the frame, limbs, string, and trigger mechanism. These elements are the foundation that enables the weapon to generate power and release bolts with precision. Knowing the construction of these parts allows you to assess their wear and tear and identify when they need maintenance or replacement.

Importance of Proper Assembly

Proper assembly and alignment of all parts are critical for both accuracy and safety. Even minor misalignments can result in decreased performance or malfunction. Regular inspection ensures that all components remain securely attached and function smoothly, minimizing the risk of damage during use.

How to Read the Ravin R20 Parts Diagram

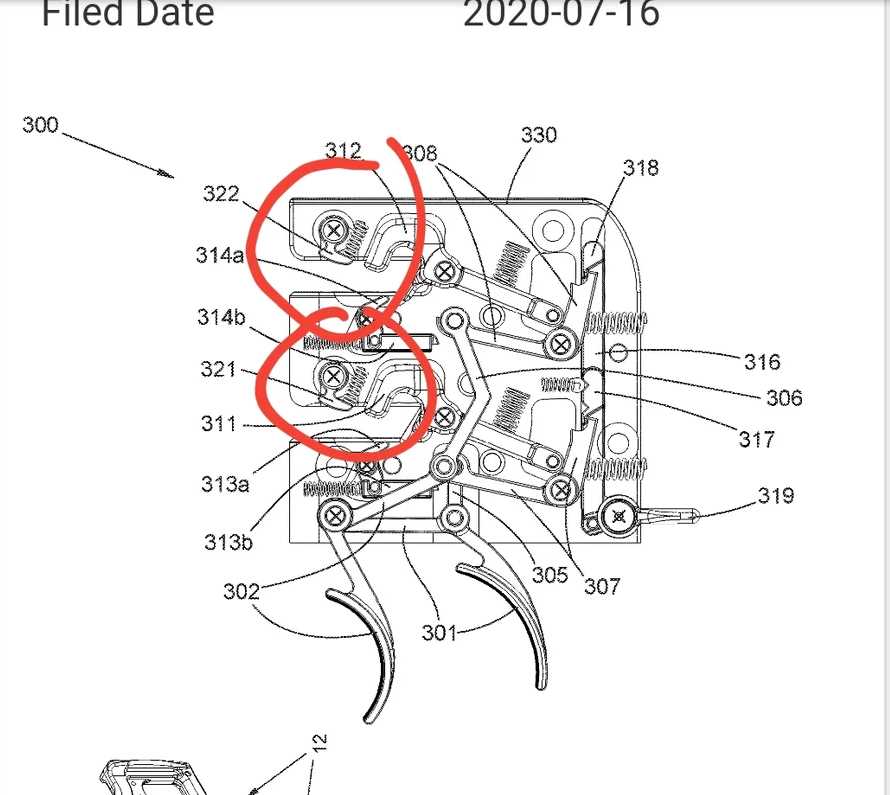

Understanding a visual representation of your crossbow’s components is essential for effective repairs and maintenance. These schematics break down the entire assembly into individual sections, helping you identify each element and its corresponding function. With the right knowledge, you can easily navigate these illustrations to find what you need.

Identifying Key Components

Each part is typically labeled clearly, often with reference numbers or labels that match the included list of components. Pay attention to these identifiers to make sure you’re looking at the correct section for the right replacement or adjustment. Understanding the function of each part allows you to locate issues and repair or replace specific components accurately.

Understanding the Layout

Visual layouts are organized in a way that mimics the actual assembly. Some illustrations may show components in exploded views, allowing you to see how each part connects to others. This helps you visualize the order of assembly and the relationship between parts, giving you a clearer idea of how to approach the disassembly or maintenance process.

Common Issues with Ravin R20 Parts

Every mechanical device is subject to wear and tear over time, and your crossbow is no exception. Common issues often arise with specific components that can affect performance, safety, and overall reliability. Recognizing these problems early helps you address them before they escalate, ensuring your equipment remains in top condition.

String Wear and Damage

One of the most frequent problems is the degradation of the string. Continuous use and exposure to environmental factors can cause it to lose its tension or fray. Regular inspection is essential to detect signs of wear, and replacing the string as soon as it shows signs of damage helps avoid misfires and other complications.

Trigger Mechanism Malfunctions

The trigger mechanism is another common area for issues. Misalignments or damage to the internal parts can result in inconsistent firing or safety issues. Routine cleaning and lubrication of the trigger components can prevent many of these problems and ensure smooth operation.