When it comes to maintaining complex machinery, having a clear visual reference for all components is crucial. A comprehensive schematic provides a detailed overview, helping users identify each part and understand its function within the system. Whether you’re a technician or a DIY enthusiast, this guide is designed to simplify repairs and maintenance tasks.

Understanding how each piece works together can save you time and effort when troubleshooting. With the right information at hand, you can quickly pinpoint faulty components and perform necessary replacements. This resource offers a clear path for anyone looking to keep their equipment running smoothly.

Knowing your machine’s layout not only aids in identifying parts but also enhances your ability to follow proper maintenance procedures. Having a reliable reference is key to reducing downtime and extending the lifespan of your equipment.

Understanding Equipment Layout and Components

Having a clear representation of a machine’s layout is essential for efficient maintenance and repairs. It allows users to visualize how different elements are connected, making it easier to identify potential issues and carry out the necessary fixes. This section will help you grasp the importance of a schematic that outlines the arrangement and functions of each individual component.

How the Layout Helps in Troubleshooting

A well-detailed schematic serves as a map for troubleshooting. By showing how each part interacts with the rest, it helps pinpoint malfunctioning areas quickly. This knowledge is particularly beneficial when working with complex systems where even a small error can affect overall performance.

Identifying Components and Their Functions

Understanding the function of each component is key to effective maintenance. Once you recognize each part’s role in the system, it becomes much easier to replace faulty items and perform general upkeep. Whether you’re addressing a minor issue or conducting a full overhaul, knowing the layout helps streamline the process and minimizes errors.

How to Use the Equipment Layout

Utilizing a schematic effectively is crucial for ensuring proper maintenance and repair of machinery. This visual guide allows you to identify and locate each element within the system, providing a straightforward way to address issues. Whether you are diagnosing a malfunction or replacing a component, knowing how to read and interpret this layout will save both time and effort.

Step-by-Step Guide for Identification

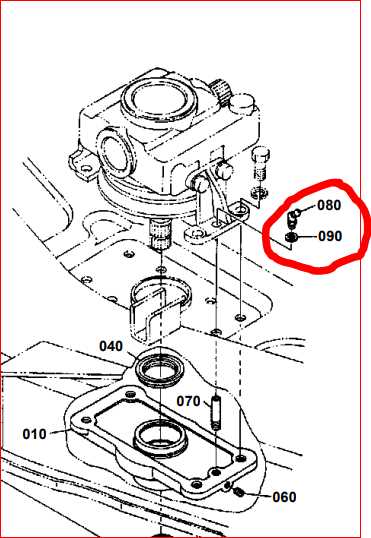

The first step in using the schematic is understanding how to locate each component. By following the visual cues and labels, you can match each item with its corresponding physical counterpart. This process is essential for ensuring that no parts are overlooked during maintenance or repair tasks.

Using the Layout for Efficient Repairs

Once you’ve identified the faulty or worn-out parts, the layout helps guide the disassembly and reassembly process. It ensures that every part is properly installed in the correct orientation. With a clear visual reference, you can avoid mistakes and ensure the system runs as efficiently as possible.

Common Issues and Part Replacements

Throughout the life cycle of any complex system, wear and tear can lead to various issues that affect its performance. Recognizing these common problems early on and replacing the malfunctioning elements can prevent more serious damage. This section highlights the most frequent issues that occur, along with guidance on how to handle replacements effectively.

Frequent Problems and Their Causes

Many issues arise from components wearing out over time due to regular use. Common signs of malfunction include unusual noises, poor performance, or unexpected shutdowns. These are often caused by worn-out or improperly functioning parts, such as motors, gears, or seals. Identifying the root cause quickly can help minimize downtime and reduce repair costs.

How to Replace Faulty Components

Once a malfunction is identified, the next step is selecting the correct replacement. The schematic is an invaluable tool for determining the specific part you need. Ensure that the replacement part matches the specifications of the original component to maintain optimal performance. Proper installation is crucial to avoid damaging the surrounding elements or causing further issues down the line.