When maintaining or repairing outdoor power tools, knowing the internal structure and how each element fits together is crucial for optimal performance. Whether you are replacing damaged components or assembling a new device, understanding the layout of the parts ensures that everything works as intended.

Key Components and Their Functions

Each tool consists of various essential elements that perform specific roles, contributing to its overall functionality. These parts are typically organized in a logical manner, ensuring that they complement one another for efficient operation.

Motor and Power Source

The motor is the heart of the machine, providing the necessary force to drive all the functions. It is powered by either a fuel source or electricity, depending on the design. Ensuring the motor remains in good condition is critical for maintaining peak performance.

Control Mechanisms

Control systems such as triggers, levers, and switches are vital for operation. They enable the user to start, stop, or adjust settings according to the task at hand. Proper maintenance of these controls prevents malfunction and ensures ease of use.

Maintenance and Replacement Tips

Regular checks and replacements are necessary to avoid breakdowns. When inspecting or replacing elements, always refer to a detailed guide for proper installation steps. Here are some maintenance steps:

- Regularly clean the components to prevent wear and tear.

- Check for loose parts that may affect stability.

- Ensure the power source is functioning correctly for reliable use.

Replacement Guide

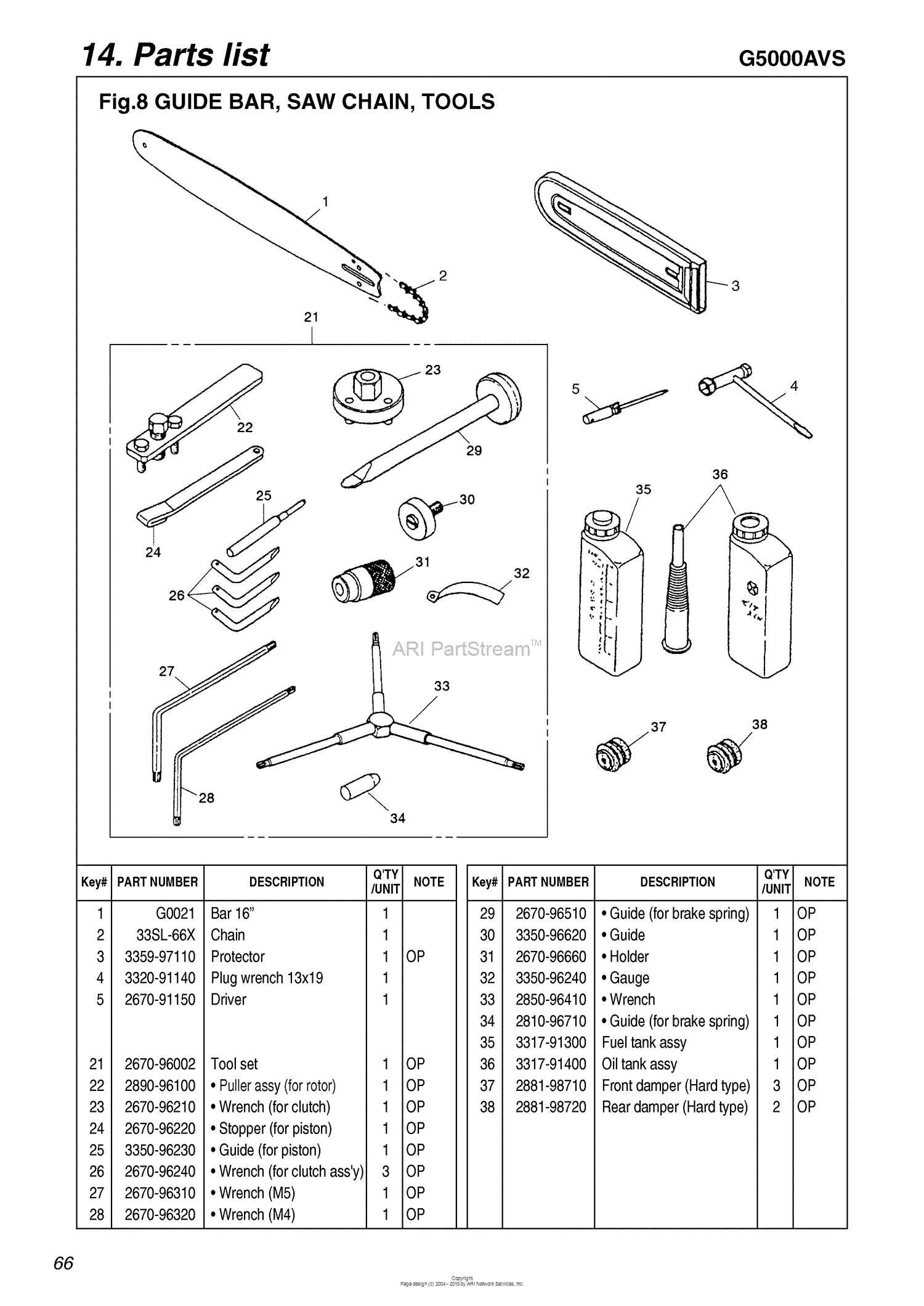

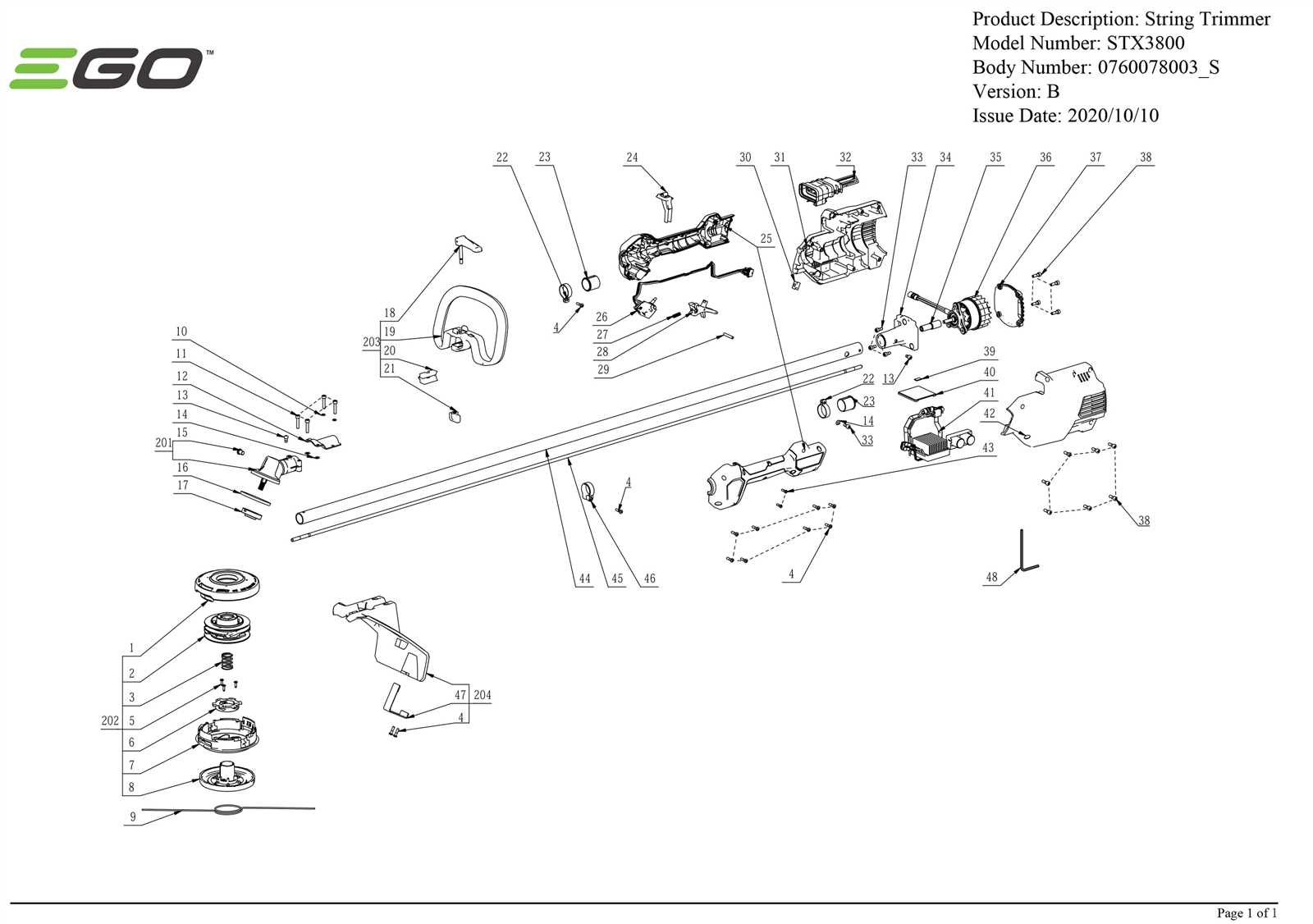

If a part becomes damaged or unusable, it’s important to source the correct replacement. Compatibility is key, so always refer to the detailed charts provided by the manufacturer to ensure you choose the right part.

By understanding the structure and functions of your tool, you can ensure longer lifespan and more efficient operation.

Detailed Guide to Equipment Components and Assembly

When it comes to assembling or servicing outdoor machinery, a clear understanding of its internal structure and how each component connects is essential. This section provides a comprehensive overview of the different elements involved, ensuring that users can identify, replace, or repair parts with confidence. Having access to a well-organized reference for each component allows for smoother operations and minimizes downtime during maintenance.

Identifying the Key Elements

The machine consists of several critical elements that contribute to its functionality. Each part is designed to fulfill a specific role, ensuring seamless operation when they work together. Knowing where these components are located and their respective functions can help avoid unnecessary confusion during repairs or assembly. It’s important to identify the main sections, such as the motor, control system, and structural supports, to understand how they interact.

Step-by-Step Replacement and Maintenance

Proper maintenance and timely replacement of faulty components are key to extending the life of any tool. With the right resources, users can follow a step-by-step guide to remove and replace worn-out parts. Always consult the provided reference material to ensure compatibility and secure assembly. Regular cleaning and inspection also help to prevent issues from escalating and keep the machine functioning optimally.