Proper maintenance of any machinery is essential to ensure its longevity and efficient performance. One of the key aspects of maintaining your tools involves understanding their individual components and how they work together. A clear visual guide can be immensely helpful for this purpose, allowing you to quickly identify parts and make informed decisions during repairs or replacements.

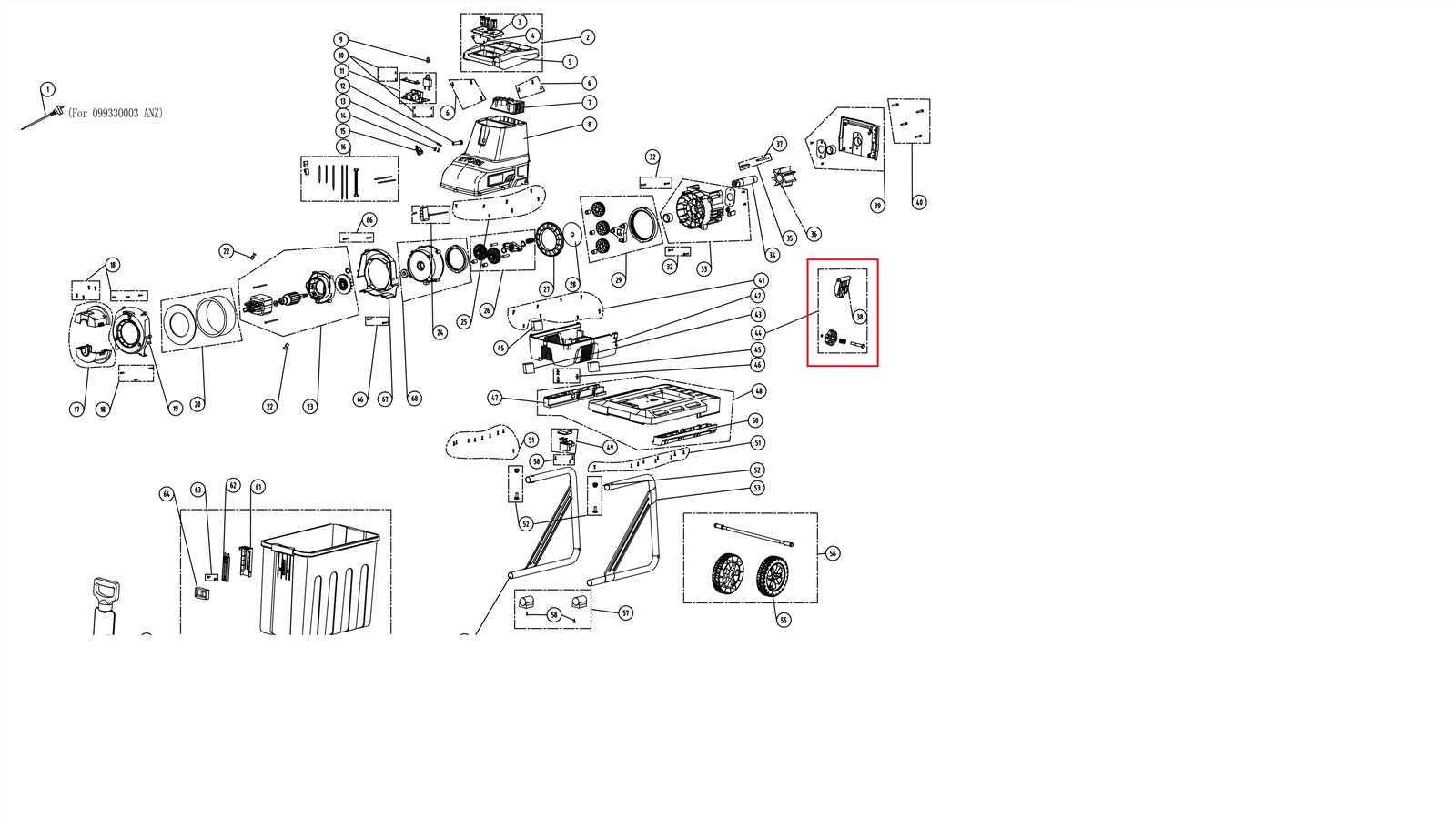

In this section, we will provide an in-depth look at the layout of essential components, helping you to recognize various pieces that are critical to the functioning of your equipment. Whether you are familiarizing yourself with the machine for the first time or performing routine upkeep, knowing how everything fits together is a crucial step.

Efficient maintenance relies heavily on the ability to locate and replace parts as needed. This guide will support you in identifying the necessary elements and understanding their roles in keeping your tool running smoothly.

Understanding the Equipment Layout

When working with machinery, it’s crucial to have a clear understanding of how its components are arranged and interact. A well-structured layout can simplify repairs and maintenance tasks, allowing you to quickly pinpoint any issues. This section focuses on familiarizing you with the essential structure of your tool, helping you navigate its key elements with ease.

Key Elements to Recognize

Identifying the various components is the first step in understanding the overall configuration. These pieces can range from the main housing to smaller accessories that play vital roles in the functionality of the equipment. Below are some of the main categories of components you should know:

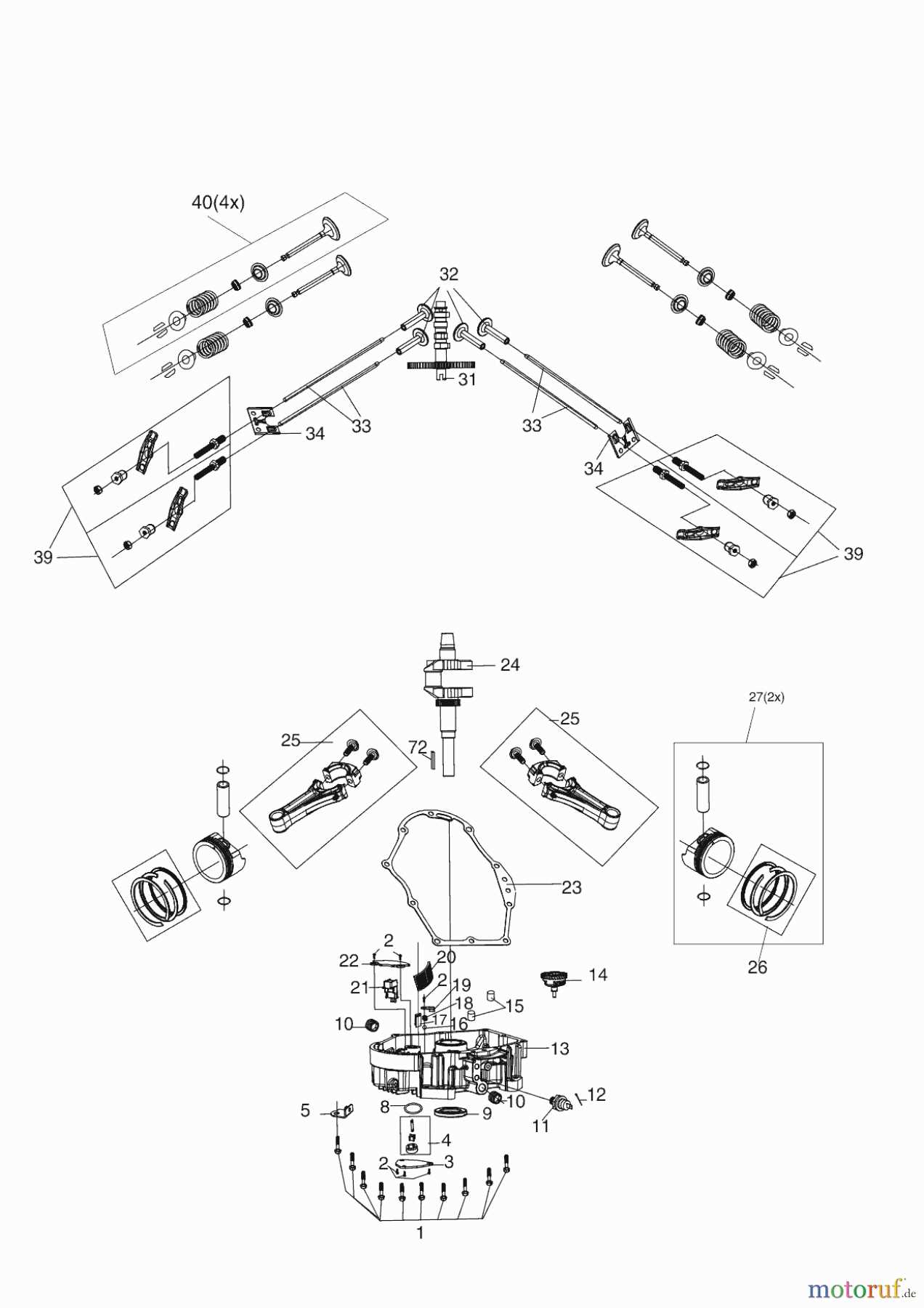

- Engine components – These are the core elements responsible for the overall operation of the machine.

- Support structures – These parts provide stability and house the main components.

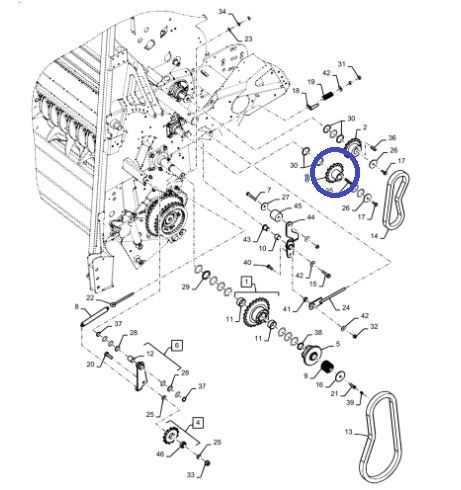

- Drive systems – Responsible for transferring power from the engine to other parts of the machine.

- Accessory attachments – These pieces enhance the versatility and function of the equipment.

How the Components Fit Together

Once you’ve familiarized yourself with the individual parts, it’s important to understand how they fit together. Proper alignment and placement are essential for the machine to function correctly. Pay close attention to how each component connects, as improper assembly can lead to performance issues or damage.

With a clear understanding of the components and their layout, you will be better equipped to maintain and repair your equipment effectively, ensuring it continues to perform at its best.

How to Identify Key Components

Recognizing the individual elements within your machinery is essential for effective maintenance and repair. Understanding each component’s role will allow you to address issues quickly and efficiently. This section guides you through the process of identifying the most important parts of the equipment, helping you gain a clearer understanding of its structure and function.

Examining the Key Sections

Start by focusing on the major sections of the tool. These areas typically house the most crucial components and should be easily identifiable. Key sections to focus on include:

- Power unit – The core section that drives the entire machine, often housing the engine or motor.

- Operational controls – These are the switches, levers, and buttons used to operate the tool effectively.

- Movement mechanisms – The components that allow the machine to move or adjust its position.

- External attachments – These parts can be removed or adjusted to suit different tasks.

Using a Visual Guide for Identification

A detailed visual reference can be incredibly helpful when trying to identify various components. By comparing the actual equipment to a diagram or reference image, you can more easily pinpoint specific sections and understand how they fit into the overall structure.

Proper identification of components helps streamline repairs and ensures that you can perform maintenance with accuracy. Having this knowledge makes it easier to replace malfunctioning parts or upgrade specific sections when necessary.

Steps for Replacing Key Components

Replacing worn-out or damaged components is an essential part of maintaining your equipment. Proper replacement not only ensures the longevity of your tool but also helps maintain its efficiency and functionality. In this section, we outline a step-by-step guide for replacing crucial elements, ensuring you can perform the task safely and correctly.

Preparation for Replacement

Before you begin, gather the necessary tools and replacement parts. Make sure you have a clear understanding of which components need to be replaced. It is important to turn off and disconnect the machine from any power sources to avoid accidents. Always wear appropriate safety gear during the replacement process.

- Identify the faulty part – Inspect the tool carefully to determine which component requires attention.

- Gather tools – Ensure you have the right tools to remove and replace the part, such as wrenches or screwdrivers.

- Prepare the new component – Have the replacement part ready and check for compatibility with the existing system.

Replacing the Component

Now that you are prepared, it is time to remove the old part and install the new one. Follow these steps carefully to avoid damaging any other components during the process.

- Remove the faulty part – Use the appropriate tools to loosen and remove the damaged part, making sure to keep track of any screws or fasteners.

- Install the replacement part – Align the new component properly and secure it in place, ensuring it is tightly fitted.

- Test the machine – Once the new part is installed, power the equipment back on and test it to ensure proper functionality.

By following these steps, you can easily replace essential components and restore your equipment to peak performance. Regular maintenance and timely replacements help to avoid unexpected breakdowns and prolong the life of your tools.