When it comes to maintaining your outdoor machinery, having a clear understanding of its individual components is essential. Knowing how each part functions and interacts with others ensures smoother operation and easier repairs. In this section, we will explore a comprehensive guide to the crucial elements of a popular model, allowing for efficient troubleshooting and replacements.

Detailed insights into each part and their locations can save time during maintenance and improve the overall performance of your equipment. By understanding how to identify and replace damaged elements, you can extend the lifespan of your device.

Whether you’re a beginner or an experienced user, a thorough grasp of the mechanical setup will enhance your confidence in handling routine maintenance or unexpected issues. Effective maintenance is key to ensuring that your tools remain in top working condition for years to come.

Redmax GZ25N Parts Overview

Understanding the structure of outdoor machinery is essential for effective operation and repair. Each device consists of various components, all of which play a vital role in its functionality. In this section, we will explore the key elements that make up the assembly, providing you with a clearer picture of how each one contributes to the overall performance.

Core Components

The heart of any mechanical system lies in its core parts. These include the engine, drive components, and controls, all of which must be in good working condition to ensure smooth operation. The proper alignment and functionality of these elements are critical for optimal performance and longevity.

Supporting Elements

In addition to the main parts, supporting elements such as filters, fasteners, and connectors are also crucial for maintaining system integrity. These parts ensure that the core components function correctly and help prevent wear and tear over time. Regular checks and timely replacements of these smaller elements can greatly extend the lifespan of your equipment.

Identifying Key Components for Repairs

Proper maintenance begins with recognizing the key elements that require attention. Knowing which parts are most susceptible to wear and understanding their roles within the system allows for more effective troubleshooting and repairs. In this section, we will guide you through the essential components to check when performing maintenance on your machinery.

Critical Functional Elements

Certain parts are integral to the smooth operation of the equipment. These include the engine, fuel system, and moving mechanisms. Identifying wear or damage in these critical areas is essential to ensure optimal performance and prevent further damage during use. Regular inspection of these components is recommended to maintain functionality.

Secondary Elements for Longevity

While secondary elements like connectors, filters, and seals may not directly affect performance, they play a crucial role in maintaining the overall health of the equipment. Keeping these components in good condition helps to prevent breakdowns and extends the lifespan of your machinery. Routine checks and replacements are key to keeping these parts functioning smoothly.

Understanding the Assembly

Having a clear understanding of how the different elements of a machine fit together is crucial for efficient use and maintenance. The assembly consists of a combination of primary and secondary components, each contributing to the overall functionality. In this section, we will break down the structure of the system and how each part plays its role in making the equipment perform at its best.

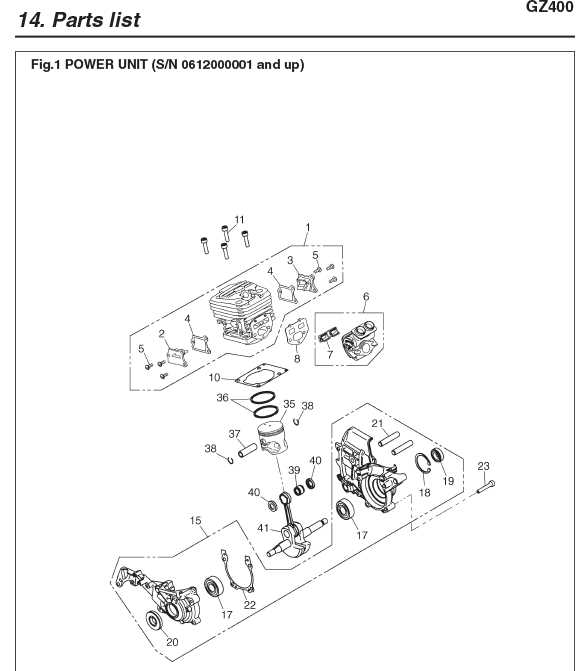

Primary System Overview

The main system consists of key functional elements that drive the overall operation. These include the power unit, control systems, and mechanisms that facilitate movement. Understanding how these components interact ensures proper handling and easier identification of potential issues.

Supporting and Auxiliary Components

Alongside the primary systems, there are supporting components that help maintain the integrity of the machinery. These include connectors, fasteners, and smaller components that contribute to smooth functioning. Regular checks and proper maintenance of these elements prevent wear and keep the equipment running smoothly for longer periods.