When working with any mechanical device, having a clear understanding of its internal structure is crucial for effective maintenance. Knowing where each piece fits and how it functions ensures smooth operation and longevity. Whether you’re replacing worn-out elements or conducting routine checks, it’s important to have a detailed guide that shows how everything connects.

Efficient repair procedures rely on recognizing the right parts that need attention. This knowledge helps you avoid costly mistakes and improve the performance of your equipment. Properly identifying faulty components and replacing them in time can prevent more serious issues down the road.

Understanding each part’s role is key to avoiding unnecessary repairs. A well-maintained system works more efficiently and lasts longer, giving you the confidence to tackle small issues before they escalate. This guide will walk you through everything you need to know to keep your equipment in top condition.

Understanding the Remington RM2510 Parts

To maintain any tool or device, it’s essential to have a clear view of its internal mechanics. Familiarizing yourself with the essential components helps you ensure proper functionality and troubleshoot effectively. Each element serves a specific role, contributing to the overall performance, and knowing how they interact is the first step to successful maintenance and repair.

Identifying Key Components

Every machine consists of numerous smaller pieces, each designed for a specific function. Some parts are critical for operation, while others are more auxiliary in nature. Understanding their arrangement within the system helps you identify which parts need attention or replacement when issues arise. A well-organized system ensures smooth performance and reduces the likelihood of malfunction.

Common Issues and Component Wear

Over time, certain parts can wear out due to regular use, causing decreased performance. It’s important to know which components are more prone to damage, such as those subjected to friction or constant movement. Regular inspection and understanding how to replace these worn elements will prolong the device’s lifespan and prevent unnecessary breakdowns.

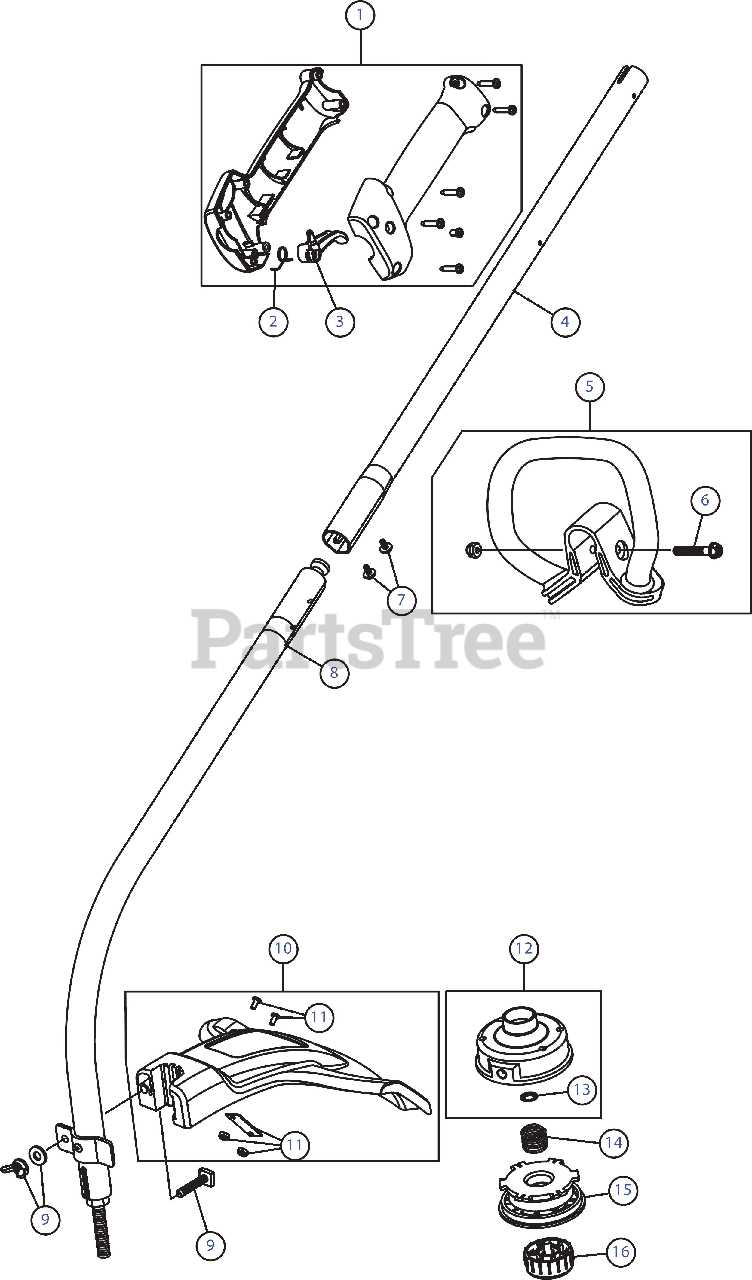

How to Read the RM2510 Parts Diagram

Understanding a visual guide to the components of a device is crucial for anyone looking to perform maintenance or repairs. These illustrations offer a clear representation of how the individual elements are arranged and connected. By learning to read and interpret these visuals, you can quickly identify any damaged or worn-out sections, making the repair process more efficient and straightforward.

Breaking Down the Symbols and Labels

Each section of the visual guide is accompanied by labels that identify specific components. These labels often include numbers or codes that correspond to part names or serial numbers. Recognizing these symbols allows you to locate each piece easily within the system, ensuring you’re working with the correct part when conducting repairs or replacements.

Understanding Component Relationships

In addition to individual labels, these diagrams often show how parts are connected or interact with each other. Arrows and lines can help illustrate movement, attachment points, or flow paths. By paying attention to these relationships, you can understand how each piece contributes to the overall function, which is essential when troubleshooting or replacing any part of the system.

Essential Remington RM2510 Spare Parts

To ensure the longevity and smooth performance of any machine, having access to key replacement components is essential. Some elements experience more wear and tear than others, requiring timely replacements to prevent malfunctions. By focusing on these vital components, you can avoid costly repairs and keep the system running efficiently for a longer period.

Certain pieces, such as motors, gears, or blades, often require attention due to their high usage. Regularly inspecting these items and replacing them when necessary can prevent major issues and reduce downtime. Keeping these critical parts on hand can also speed up the repair process, ensuring your equipment remains in top condition.