Every tool consists of multiple essential components that work together to ensure smooth operation. Understanding the function of each piece is crucial for effective maintenance and repair. A clear understanding of these elements can help extend the life of your equipment and improve its performance.

In this guide, we will focus on breaking down the key elements that make up cutting tools, highlighting their roles and how they contribute to overall functionality. Identifying these individual parts and knowing how they interact with one another is vital for troubleshooting and making informed decisions during repairs.

Whether you are looking to replace a specific component or performing routine checks, having access to a detailed reference can save time and effort. By familiarizing yourself with the structure of the tool, you can ensure proper maintenance and avoid unnecessary complications.

Understanding Tool Components

Every cutting tool is made up of various integral components that serve specific purposes. These pieces work together to ensure precise functionality and efficiency. Recognizing the role of each element is essential for maintaining the tool and optimizing its performance over time.

Key Elements of the Tool

The structure of any tool includes a range of different parts, each contributing to the overall functionality. From the motor to the cutting mechanism, each section is designed with a specific task in mind. By familiarizing yourself with these components, you can troubleshoot issues more effectively and ensure smoother operation.

Maintaining and Replacing Components

Proper upkeep of the tool involves regularly checking each component for wear and tear. Over time, some parts may need replacing to maintain peak performance. Identifying the exact element that requires attention can save time and prevent unnecessary repairs. Regularly replacing worn-out components helps avoid costly breakdowns and improves longevity.

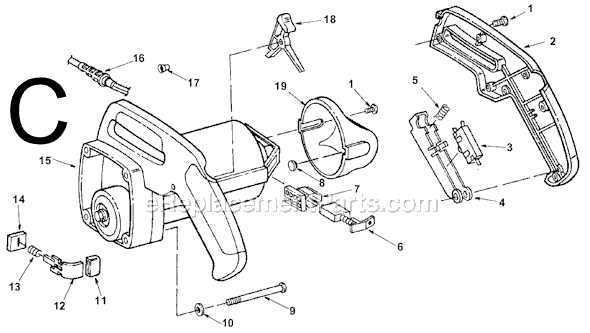

How to Identify Cutting Tool Components

Recognizing the individual components of a cutting tool is essential for effective maintenance and troubleshooting. Understanding how each piece functions allows you to make informed decisions when repairing or replacing parts. Identifying the correct element is key to preventing unnecessary damage and ensuring smooth operation.

Start by familiarizing yourself with the overall design of the tool. Each section has a specific role, from the motor to the moving parts. A clear understanding of the structure will make it easier to spot issues and determine what needs attention.

When inspecting your tool, take note of any visible markings or labels that indicate the component’s name. If a part appears damaged or worn, refer to the manufacturer’s reference guide for detailed descriptions and visual aids to help you identify the correct replacement part.

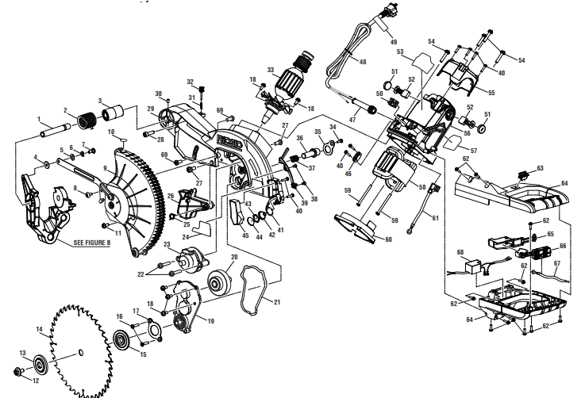

Importance of Accurate Component Schematics

Having access to precise schematics of a tool’s components is vital for efficient repairs and maintenance. Clear visual references allow you to easily identify each element and understand how they work together. This knowledge simplifies the process of troubleshooting and ensures that you can make the right decisions when parts need replacing or adjusting.

Accurate schematics help prevent mistakes during repairs. By using a reliable reference, you can ensure that each component is correctly identified and replaced, reducing the risk of damage or improper assembly. It also allows for a more efficient repair process, saving both time and effort.

Furthermore, accurate diagrams assist in locating hard-to-find or uncommon parts. When working with complex machinery, these visual guides become invaluable for quickly pinpointing specific elements, streamlining the maintenance process and enhancing the overall longevity of the tool.