When working with complex machinery, it is essential to have a clear understanding of each component and how they fit together. By recognizing the function and placement of each element, you can ensure better maintenance and a more efficient repair process. This knowledge is vital for both professionals and hobbyists who wish to optimize their equipment’s performance.

Identifying the key elements of any mechanical device can greatly enhance its longevity and functionality. Familiarizing yourself with the layout of the parts allows for a smoother repair or upgrade, reducing the risk of errors during assembly. Whether it’s a motor, blade, or frame, knowing the role of each component is crucial for troubleshooting issues and extending the tool’s life.

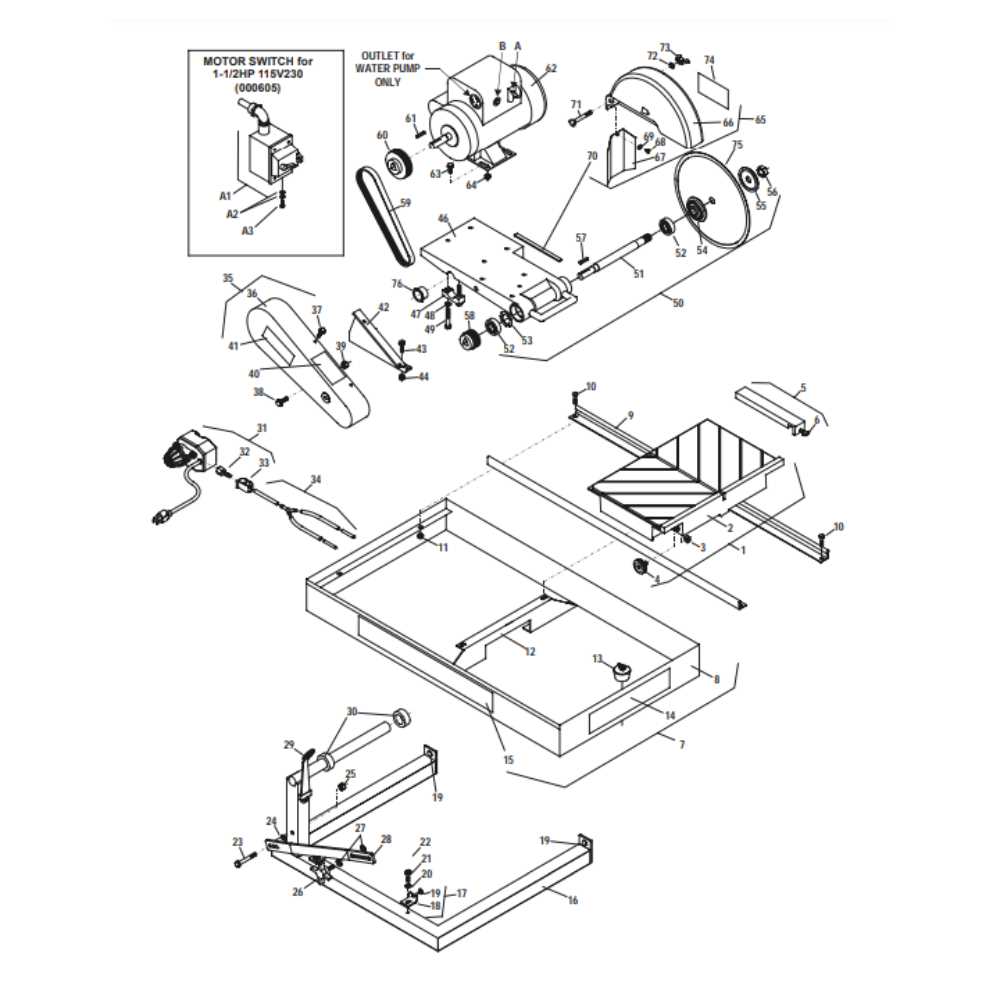

Additionally, having access to a clear, detailed visual guide can be a helpful resource. With proper identification, even those unfamiliar with the machinery can learn to recognize when a part needs replacement or adjustment. This practical approach helps maintain the equipment in top condition for longer periods.

Understanding Tool Components

When dealing with complex cutting machinery, it’s essential to comprehend how each individual element contributes to the overall function of the equipment. The arrangement and interaction of these elements determine the tool’s performance, efficiency, and longevity. Understanding each component’s purpose can lead to more effective maintenance and troubleshooting procedures.

Key components typically include the motor, rotating mechanism, and protective casing, each playing a specific role in ensuring smooth operation. These parts work in unison to deliver precision and power, while also enhancing user safety. Recognizing these elements and their functions will allow for easier identification of issues during routine checks or repairs.

Additionally, being familiar with the various components of your equipment can help in choosing suitable replacement parts when needed. A clear understanding ensures that the right parts are selected, avoiding the risk of installing incompatible components. This knowledge is crucial for maintaining optimal performance and preventing unnecessary damage.

How to Read a Machinery Layout

Interpreting a visual guide of equipment components requires attention to detail and an understanding of how parts are organized. These layouts provide valuable insight into the arrangement and connectivity of various elements, allowing users to quickly identify parts and their functions. Learning how to navigate such a guide can make maintenance and repairs much more efficient.

Begin by recognizing the symbols and labels used in the layout. Each part is often represented with specific markings that correspond to its function, size, and position within the machinery. Understanding these symbols is crucial for distinguishing between similar-looking components and ensuring that each part is properly identified.

As you examine the layout, pay close attention to the connections between parts. This will help you understand how they interact and which components are essential for the equipment’s operation. A clear reading of these connections is essential when troubleshooting or replacing damaged parts, as it ensures compatibility and proper assembly.

Common Issues and Spare Parts Identification

Understanding common problems that arise in machinery helps users quickly diagnose issues and identify which components need replacement. Being able to pinpoint the faulty parts is essential for effective repairs, ensuring minimal downtime and maintaining tool performance. Regular inspection and knowledge of typical malfunctions can prevent unnecessary wear and tear.

One frequent issue is motor malfunction, which may stem from worn-out bearings or electrical faults. Identifying these components in the machine’s layout will help pinpoint the exact part that requires attention. Similarly, problems with the cutting mechanism, such as misalignment or wear, are often caused by damaged guides or components that require replacement.

Recognizing the symptoms of a malfunction and knowing which components to replace is crucial. Whether it’s a broken drive belt or a worn-out motor brush, understanding the purpose of each element and how it affects the overall operation will make repairs easier. By consulting the component guide, users can select the correct replacements, reducing the risk of further damage and ensuring smoother operation.