Mechanical systems often rely on intricate designs to function efficiently, and one of the most essential elements in these systems involves circular structures. These components play a crucial role in ensuring proper movement and performance across various devices. Understanding how each piece works together is vital for maintenance and repair.

Detailed analysis of these components allows engineers and technicians to identify potential issues and improve the durability of the equipment. In many applications, these elements come in various forms and sizes, each serving a specific function within the larger system.

By examining the structure and relationships of these elements, users can gain a deeper appreciation for the complexities of machinery. It provides insight into how motion and force are transferred within these mechanisms, offering practical knowledge for troubleshooting and upgrades.

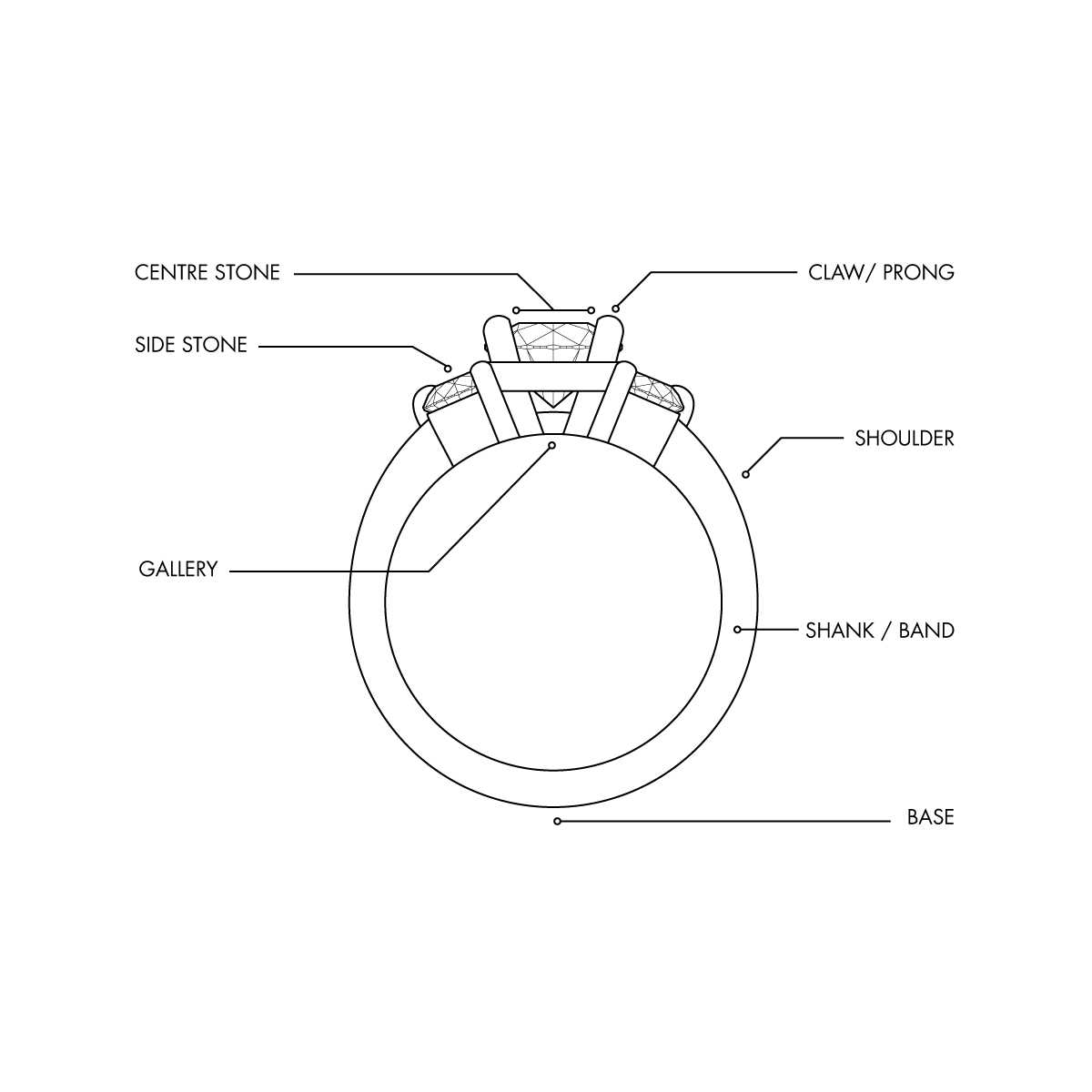

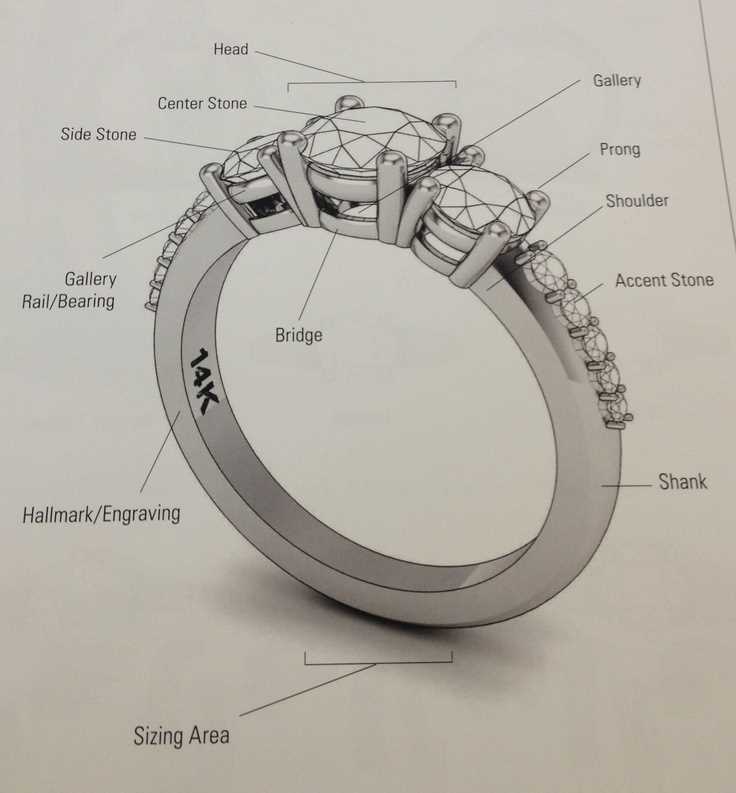

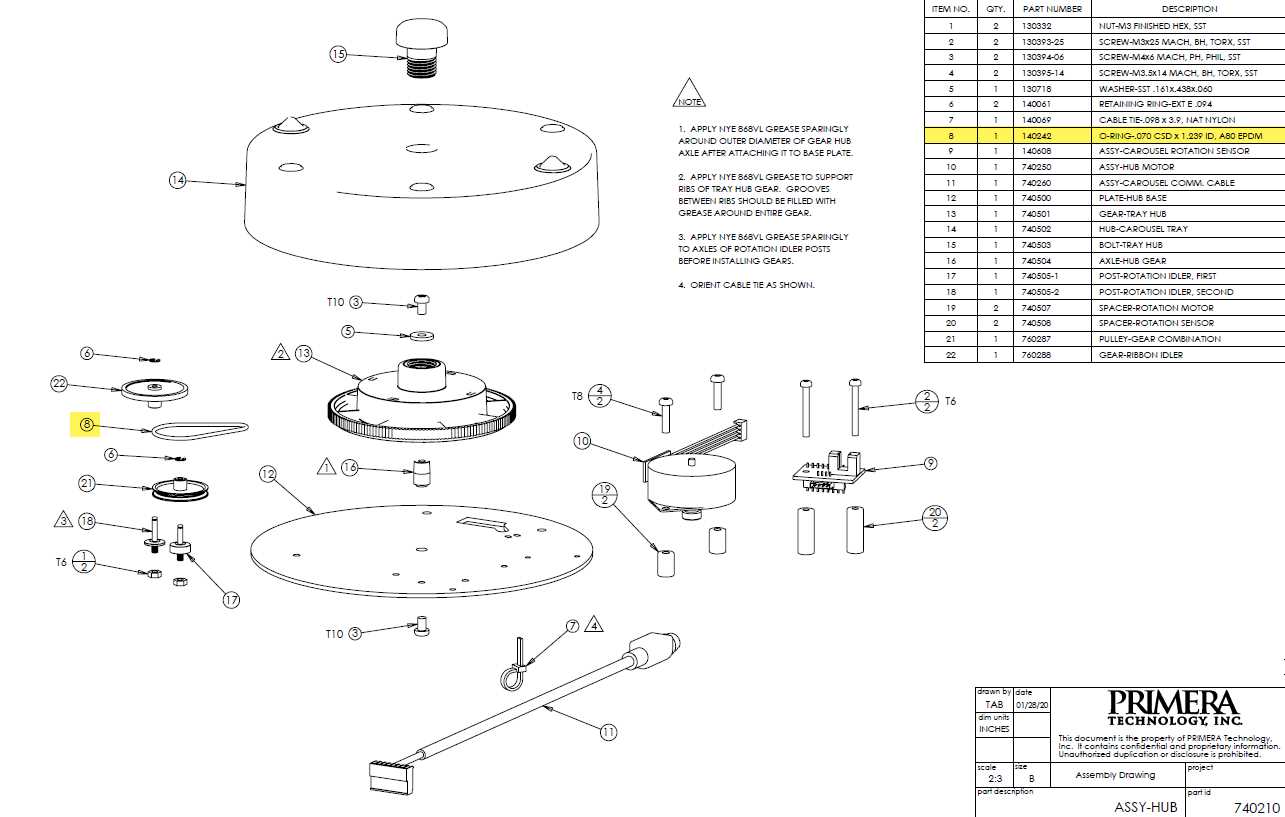

Key Components of a Circular Assembly

In many mechanical systems, circular structures serve as the foundation for stability and smooth operation. These assemblies are composed of several key elements that work in tandem to ensure optimal functionality. Each individual component has a specific role that contributes to the overall performance of the mechanism.

Central Hub and Supporting Elements

The central hub is often the primary component around which the other elements revolve. It acts as the core, providing support and anchoring the system. Surrounding it are supporting elements, which help to distribute forces evenly and prevent wear and tear. These components are essential for maintaining balance and ensuring smooth motion.

Connecting and Securing Components

In addition to the central hub, various connecting elements are necessary for holding the structure together. These can include clips, bolts, and other fasteners that ensure the integrity of the assembly. Proper attachment of these elements is crucial for the longevity and safety of the entire system, as they maintain the alignment of all parts.

How Circular Elements Interact in Systems

In mechanical assemblies, each element plays a crucial role in the system’s operation. These components work together to transfer forces, maintain motion, and ensure smooth functioning. The interaction between different elements is key to achieving efficiency and reliability in complex systems.

When these elements are in motion, they rely on each other to maintain alignment and prevent friction or misalignment. The way they are positioned and connected ensures that forces are evenly distributed, allowing the entire system to function without excessive wear. Understanding these interactions is essential for troubleshooting and improving system design.

Common Circular Designs and Variations

There are various designs used in mechanical assemblies, each serving a distinct purpose based on the system’s requirements. These configurations are tailored to optimize performance, durability, and functionality. Depending on the application, the design may vary in shape, material, and structure to meet specific operational needs.

Some of the most common designs include solid structures for enhanced strength and flexibility, while others may incorporate grooves or notches to reduce friction or accommodate different components. Variations in material composition also play a key role, as metals, polymers, and composites each offer unique advantages for particular environments and loads.