When it comes to maintaining outdoor machinery, understanding the various components is essential for efficient repairs and upkeep. Knowing how each element works together helps ensure smooth operation and prolongs the lifespan of the equipment. Regular maintenance can prevent costly breakdowns and improve performance over time.

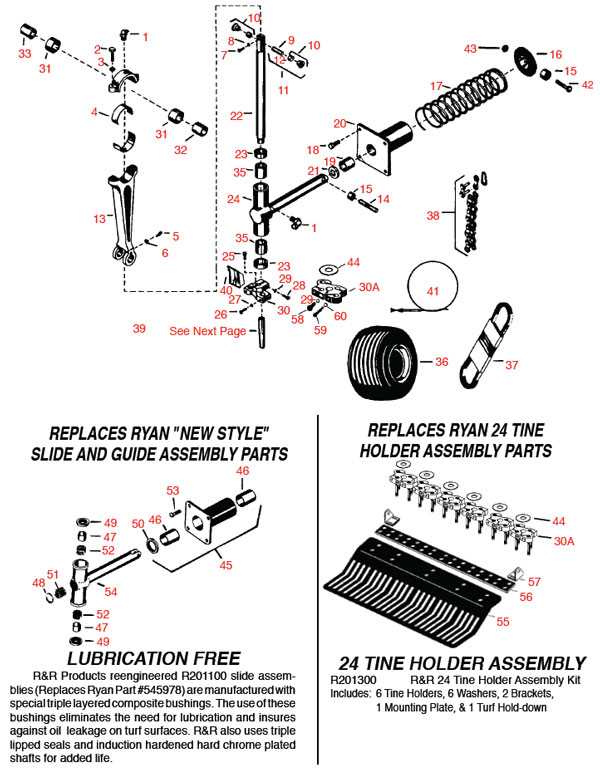

By referring to detailed visual guides, users can easily identify the individual components, understand their function, and troubleshoot any issues that may arise. This knowledge is especially valuable for those who perform routine servicing or need to replace worn-out parts. A clear and structured overview of the machinery’s internal makeup can simplify the repair process.

Having access to a comprehensive guide allows users to confidently handle any mechanical problems, making maintenance tasks less daunting and more manageable. Whether you are an experienced technician or a beginner, such resources provide clarity and support, ensuring that repairs are done correctly and promptly.

Understanding the Ryan Sod Cutter Diagram

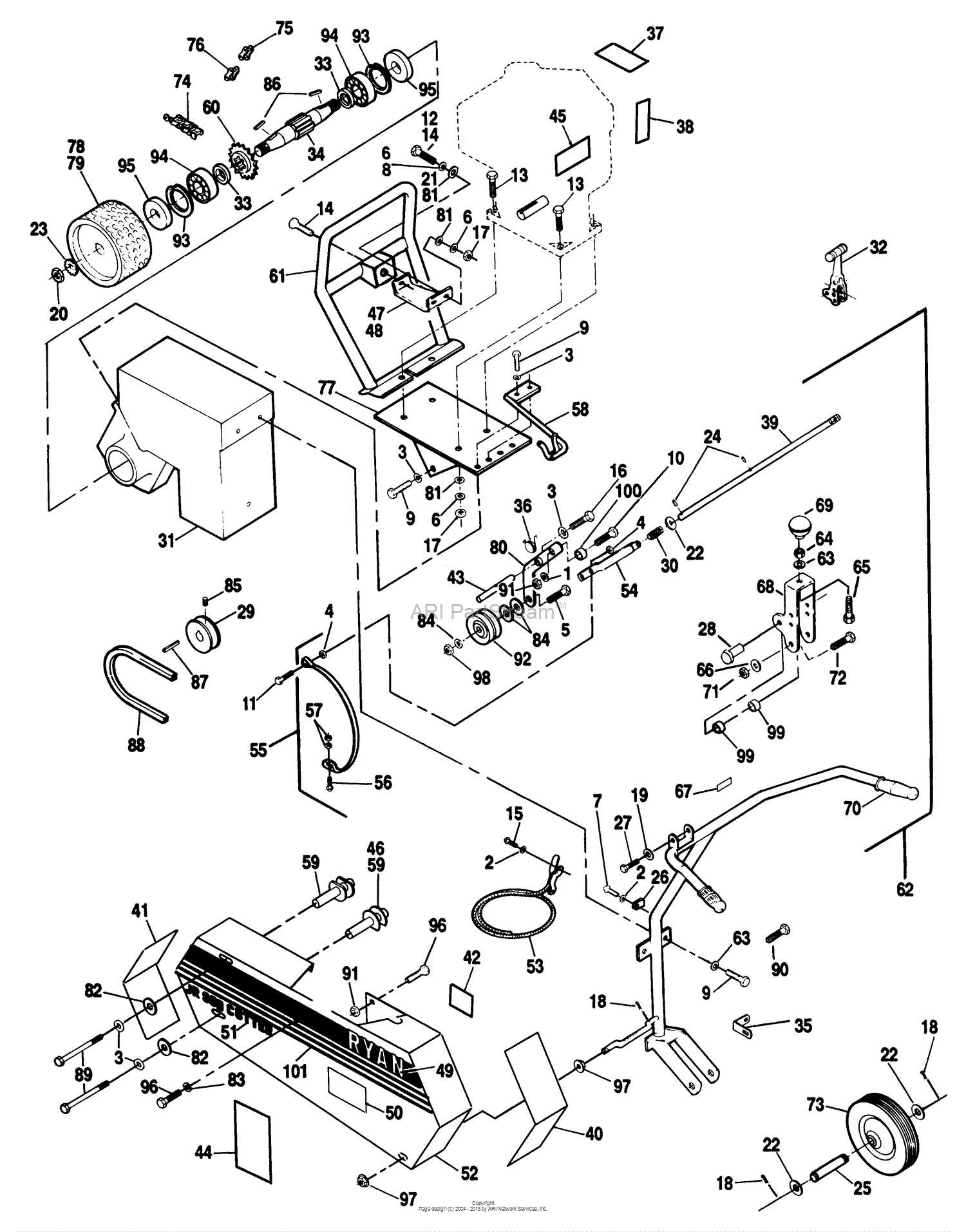

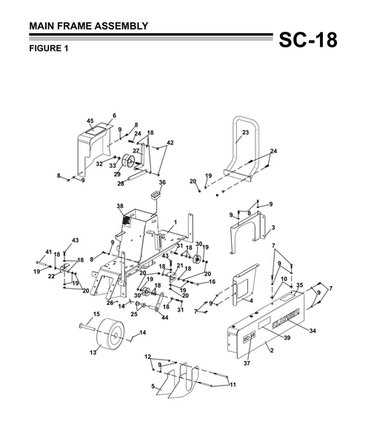

To maintain and repair outdoor equipment effectively, it’s crucial to have a clear understanding of how the machinery is assembled. A visual reference that highlights the different components is invaluable in this process. By analyzing these guides, operators can quickly locate specific sections and identify potential issues within the system.

Importance of Visual Guides

Having a visual breakdown of the machine allows users to familiarize themselves with its structure. Each part is shown in relation to others, which helps clarify how everything fits together. This understanding can be especially useful for troubleshooting or during disassembly and reassembly procedures.

How to Use the Reference for Repairs

By carefully studying the guide, users can pinpoint which elements require attention, whether it’s for replacement or simple maintenance. This reference provides a step-by-step approach to handling any mechanical difficulties, allowing repairs to be performed accurately and with minimal effort.

Common Parts of a Ryan Sod Cutter

Every outdoor machine consists of a variety of elements that work together to ensure smooth operation. Identifying these key components is essential for understanding how the equipment functions. From the main drive system to smaller attachments, each piece plays a specific role in the overall performance of the machine.

Main Drive Mechanism

The central part of the system that powers the machine is the drive mechanism. It includes the engine, transmission, and related gears that convert power into movement. Ensuring this system is functioning properly is crucial, as it enables the equipment to perform its primary task effectively.

Cutting and Digging Mechanisms

Attached to the drive mechanism are the elements that perform the cutting or digging functions. These components, often consisting of blades or other digging tools, are designed to handle the physical tasks of breaking the ground. Regular checks and maintenance of these parts are important to keep the machine working efficiently and prevent damage during use.

How to Use the Parts Diagram for Maintenance

Having a clear guide to the internal structure of your equipment can greatly simplify maintenance tasks. By referencing a well-structured visual breakdown, you can quickly identify specific components that require attention, ensuring a more efficient repair process. This guide is especially helpful for routine checks or when addressing issues that arise during use.

Step-by-Step Troubleshooting

To begin, carefully examine the image and locate the part that seems to be malfunctioning. By following the outlined steps, you can understand how the system works and how each element interacts with the others. This will help you pinpoint the source of any issues and determine whether a replacement or minor adjustment is needed.

Preventative Maintenance with Visual Aids

In addition to repairs, regular inspection is key to prolonging the lifespan of your machinery. Use the guide to assess wear and tear on components over time. Early identification of damaged or worn elements can prevent more serious problems down the road, saving you time and money on repairs.