For anyone looking to maintain or repair outdoor power tools, knowing the individual components and how they work together is essential. Proper knowledge can significantly extend the lifespan of your equipment and improve its efficiency. Whether you’re a homeowner or a professional, understanding how to identify each part and its function can save time and money on repairs.

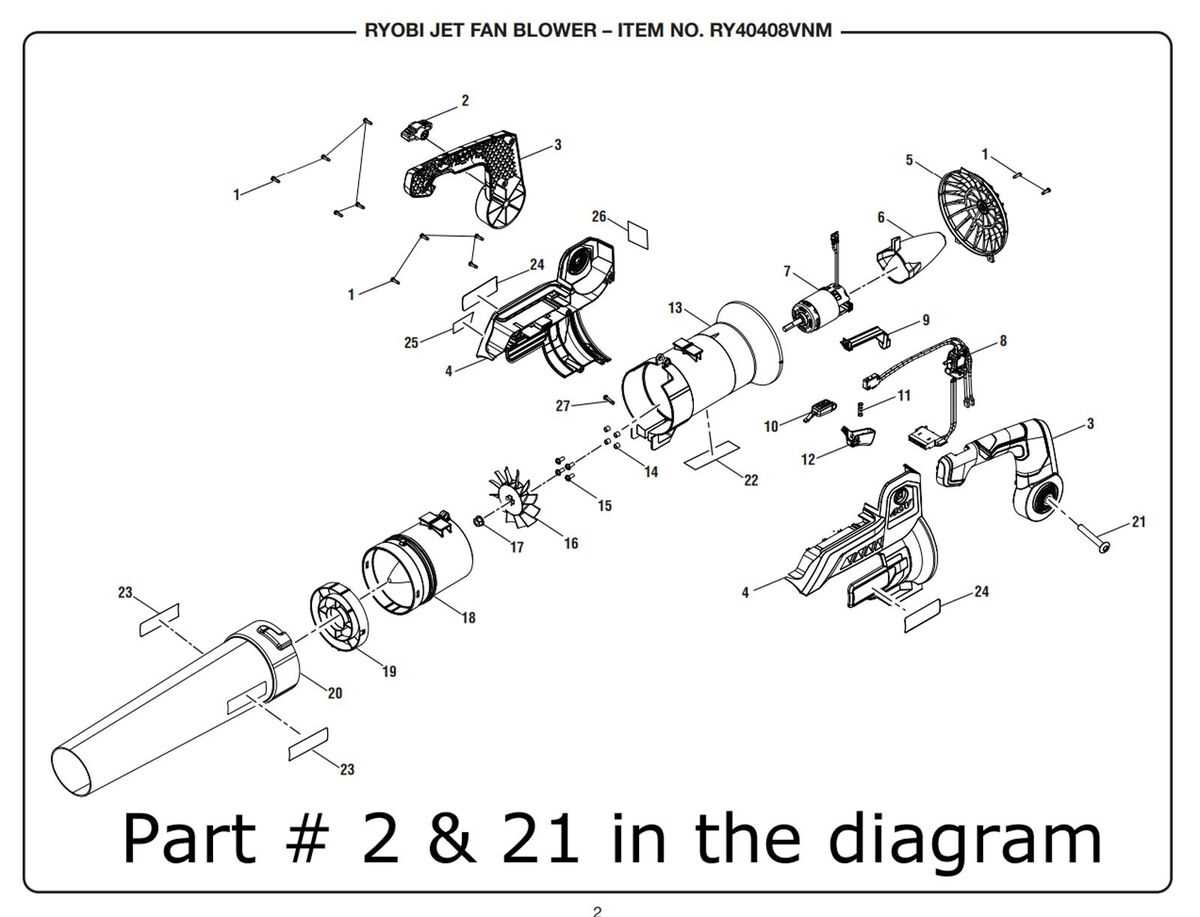

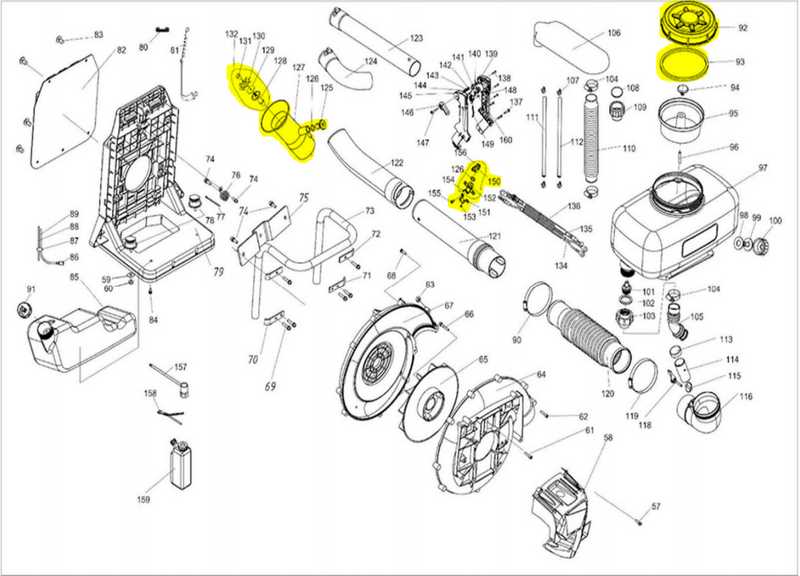

Identifying key parts is the first step in troubleshooting. Each tool comes with a schematic that shows how the various elements fit and interact. This guide will help you make sense of these technical illustrations, allowing you to perform repairs with confidence.

Regular maintenance and timely replacement of worn-out elements are critical for ensuring optimal performance. In the following sections, we will explore how to interpret these schematics and offer tips for common repairs. Understanding these details will make any repair job easier and more effective.

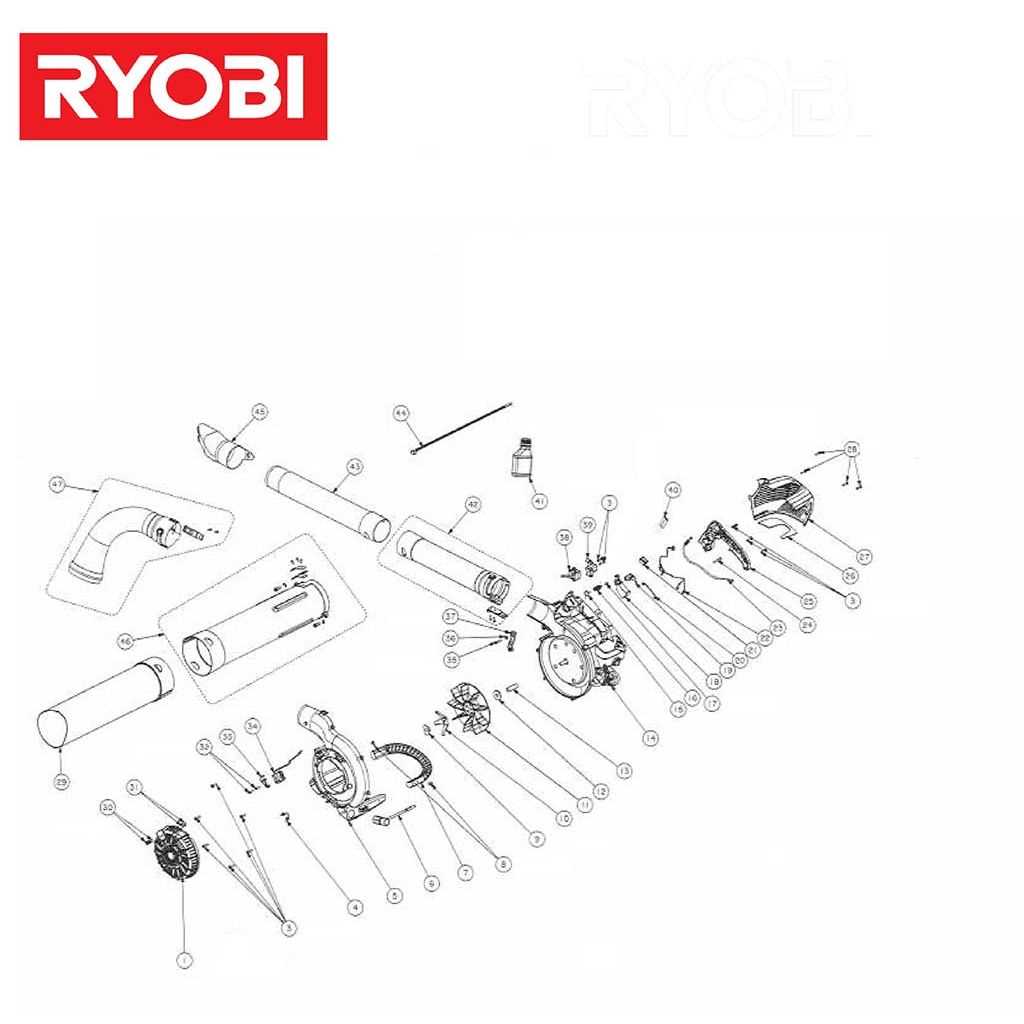

Understanding the Ryobi Backpack Blower Parts

To properly maintain and repair outdoor equipment, it’s crucial to have a clear understanding of how all the individual components come together. Each tool relies on a variety of elements working in harmony to perform effectively. Recognizing these parts and knowing their functions can help in diagnosing issues and ensuring the machine runs smoothly.

Various sections of the equipment play a vital role, from the power source to the air delivery system. The engine provides the necessary power, while the housing components keep everything secure and ensure efficient airflow. Each of these sections needs to be in good working condition to avoid malfunction and to optimize the tool’s performance.

Familiarity with the internal structure allows for easier identification of damaged or worn-out components. Whether it’s the fuel system, airflow path, or control mechanisms, recognizing each element’s role helps in making informed decisions about repairs and replacements. Having this knowledge at hand reduces downtime and ensures the longevity of the tool.

How to Use the Parts Diagram Effectively

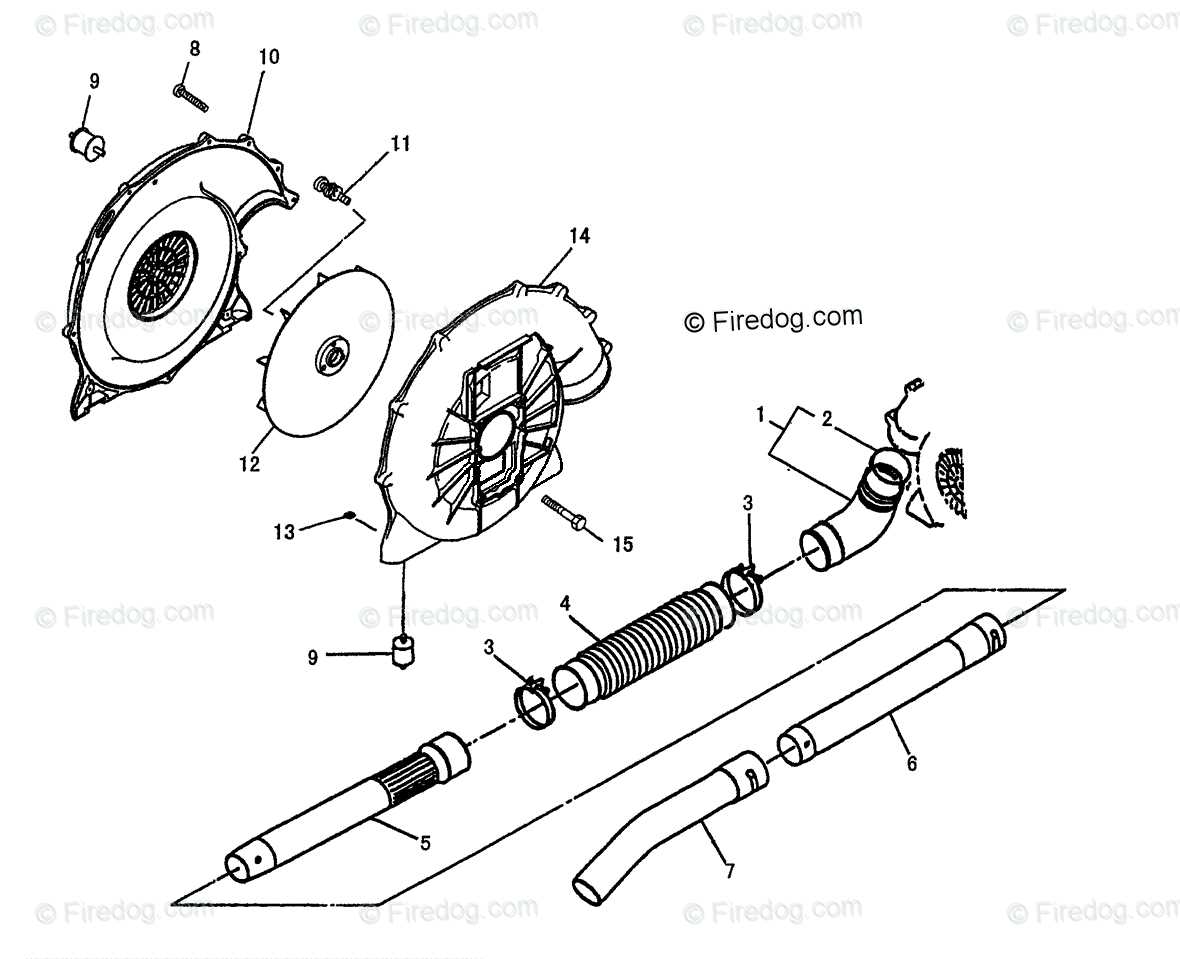

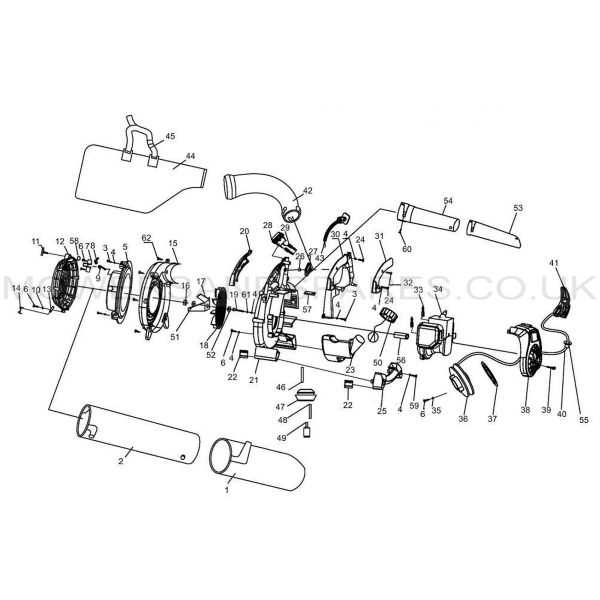

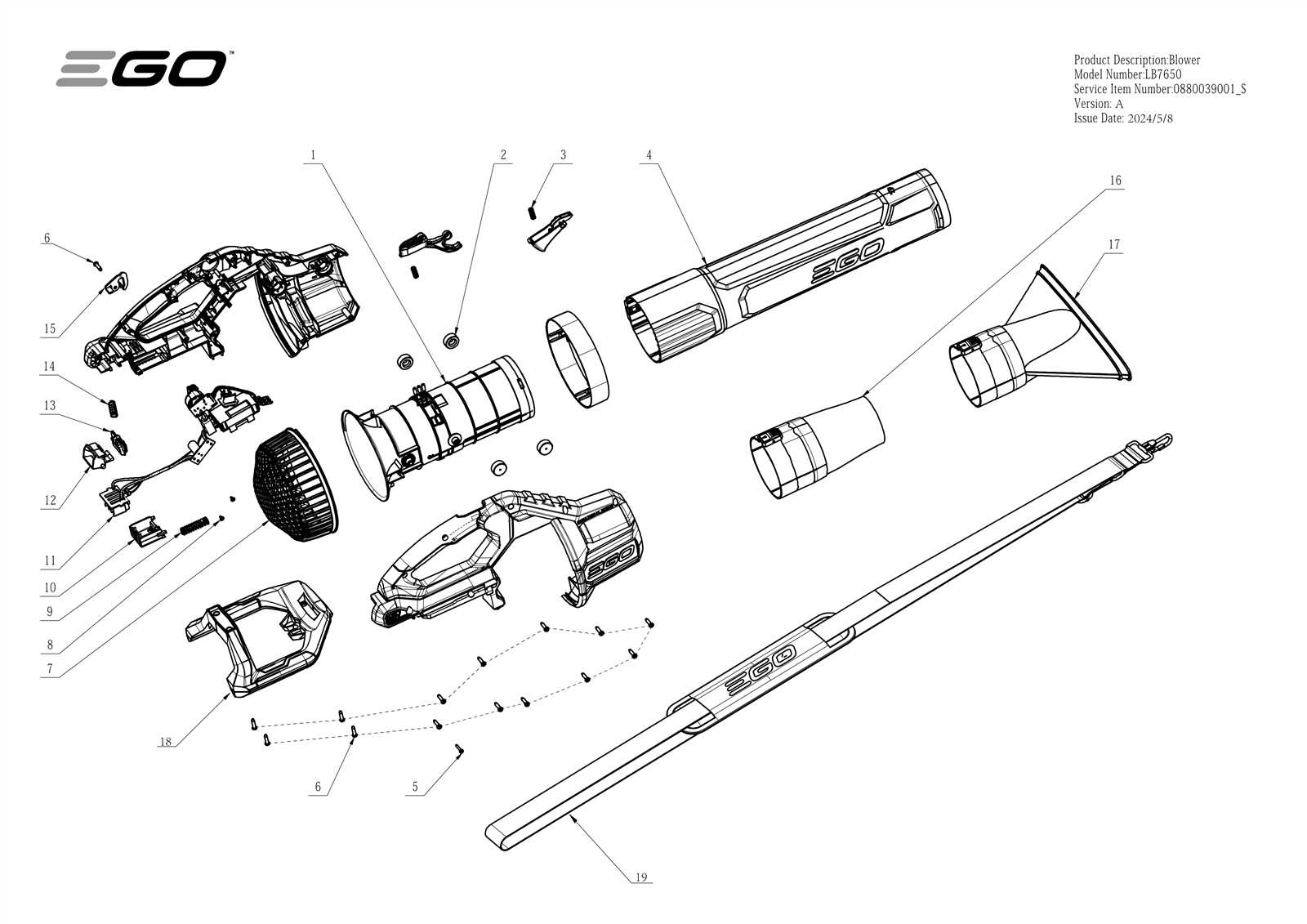

Understanding a tool’s schematic is essential for performing accurate repairs and maintenance. These technical illustrations provide a visual representation of how the different components interact with each other. With the right approach, these diagrams can guide you through troubleshooting, identifying issues, and ordering the correct replacements.

Interpreting the Illustration

The first step in using a schematic is to identify the different sections. Each part is typically labeled with a number or letter, which corresponds to its position in the overall layout. Familiarizing yourself with these labels helps you quickly locate the component you need to address.

Locating and Replacing Components

Once you’ve identified the necessary parts, you can proceed with removal or replacement. Diagrams usually show the order of assembly and disassembly, ensuring you don’t miss any crucial steps. Follow these steps carefully to avoid causing damage to other sections while replacing the worn-out components.

Common Issues and Replacement Parts

Over time, outdoor tools may experience various issues due to wear and tear. Identifying common problems early can prevent larger malfunctions and keep your equipment running smoothly. Understanding which components are likely to wear out and how to replace them ensures you’re ready to perform repairs when needed.

One common issue is a decrease in power or performance, often caused by a malfunctioning fuel system or a clogged air intake. In such cases, cleaning or replacing the fuel filter and air filters can restore efficiency. Another frequent problem is poor airflow, which may be a result of a damaged fan or blocked vents. Replacing these components will help improve airflow and overall function.

Some parts, like the ignition system or the carburetor, are prone to damage or clogging, leading to difficulty starting the tool or inconsistent performance. Replacing spark plugs or cleaning the carburetor can resolve these issues. Being familiar with which components are most likely to fail allows you to maintain your equipment effectively, reducing the risk of future breakdowns.