When it comes to maintaining outdoor power equipment, having a clear overview of the key components is essential. Knowing how each piece fits together and functions ensures smooth operation and extends the lifespan of your tools. A well-organized guide to the structure of these devices can make it easier to identify parts that need attention or replacement.

In this section, we’ll explore a detailed breakdown of how different parts of your tool interact. This will provide you with the necessary information to handle repairs, replacements, and general maintenance effectively. Whether you are troubleshooting or performing regular upkeep, having a solid understanding of your tool’s internal layout can save you time and effort.

Familiarizing yourself with the equipment’s framework helps you identify potential issues before they become serious problems. It also ensures that you are using the right components for repairs, avoiding costly mistakes. By understanding the overall assembly, you’ll be equipped to keep your tool running smoothly for years to come.

Understanding Tool Assembly Layout

Having a comprehensive view of the structure of your outdoor equipment is crucial for efficient maintenance and repairs. Every tool consists of various interconnected components, each playing a specific role in its overall function. Understanding how these elements fit together allows you to troubleshoot and make necessary adjustments with confidence.

Key Elements of the Tool Structure

The core of any tool involves a combination of the engine, handle, and attachment system. These work together to create a balanced and functional unit. A clear understanding of each component’s function within the system will help identify which parts need replacement or repair. Whether it’s the drive mechanism or the attachment points, knowing how the different parts interact is essential for long-term tool performance.

Benefits of a Clear Assembly Guide

Having access to a well-organized breakdown of your tool’s assembly allows you to spot worn or damaged parts easily. With this knowledge, performing routine maintenance becomes a straightforward task. Additionally, it ensures you are using the correct replacement parts, reducing the risk of improper repairs that could affect performance or safety.

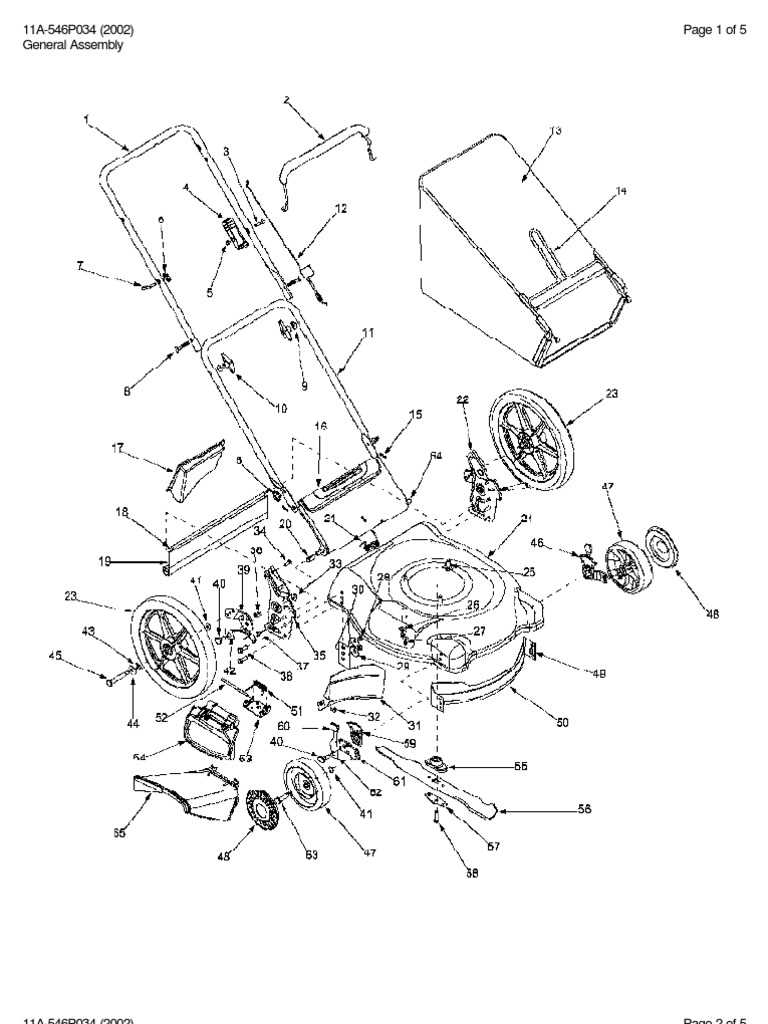

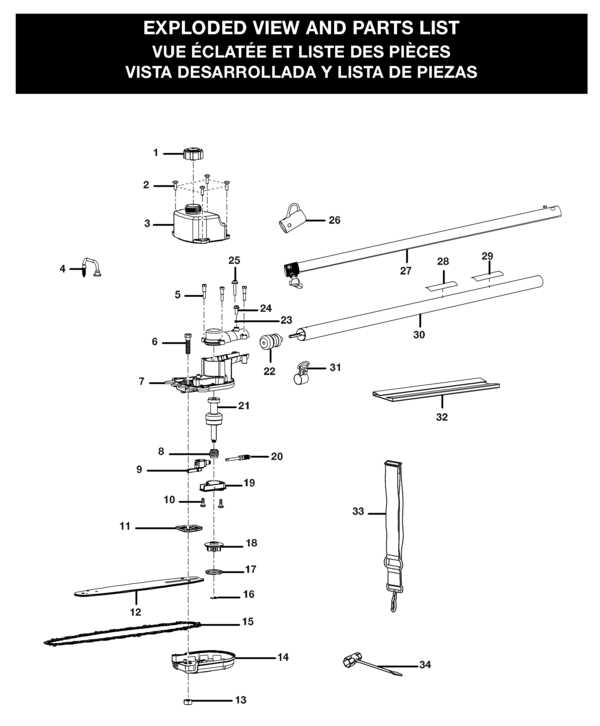

How to Identify Key Components in the Diagram

Understanding the essential elements in a technical layout can seem challenging at first. However, with the right approach, recognizing each part becomes straightforward. It’s important to carefully examine each section and understand the function it serves in the overall system. This approach allows users to efficiently pinpoint the components they need without confusion.

To begin with, focus on the labeled sections within the schematic. These labels are usually clear indicators of what each part represents. Some layouts also use visual cues, such as arrows or color coding, to distinguish different elements. By recognizing these symbols, you can quickly identify key components and their connections.

Next, pay attention to the relationship between components. Most diagrams highlight how different parts fit together and interact, which helps in understanding the structure of the system. It’s useful to identify major components first, as they often serve as the foundation for connecting smaller elements.

Lastly, referencing the accompanying manual or guide is highly beneficial. These documents often contain descriptions of the various components and their roles, providing additional context and clarity when reviewing the layout. By combining the visual information with written explanations, you can more easily navigate through the technical drawing.

Steps for Replacing Ryobi Expand-It Parts

Replacing worn-out or damaged components in a tool requires a methodical approach to ensure everything is functioning properly. Following a series of clear steps will make the replacement process smoother and help you avoid any mistakes. With the right tools and a little attention to detail, you can quickly restore your equipment to optimal performance.

- Turn off and unplug the device: Before starting, always ensure that the tool is powered off and disconnected from any power sources to prevent accidents.

- Identify the damaged components: Carefully inspect the equipment to locate the parts that need replacement. Refer to any user guides or manuals for a better understanding of the components involved.

- Gather necessary tools: Collect all the tools you will need for the replacement process, such as screwdrivers, wrenches, or pliers. This ensures you’re ready to work efficiently.

- Remove the defective part: Using the appropriate tools, carefully detach the malfunctioning component. Take note of how the part is connected for easy reassembly.

- Install the new component: Align the new part with the corresponding connections and secure it firmly in place. Ensure it fits correctly and operates smoothly.

- Test the device: Once the replacement is complete, turn the tool back on and check its functionality. Ensure everything is working as expected before use.

By following these steps, you can ensure a seamless replacement process that will keep your equipment in excellent working condition.