When it comes to maintaining and repairing machinery, understanding the internal mechanisms is essential for effective service. Identifying each element’s role helps in troubleshooting issues and ensuring smooth operation over time. This knowledge is critical for both professionals and hobbyists who wish to take care of their tools properly.

Having access to detailed visual representations of the components allows users to easily locate specific pieces and understand how they work together. This can save time during repairs and improve the overall longevity of the equipment. Being able to pinpoint exactly where a malfunction might occur also streamlines the maintenance process.

By familiarizing yourself with the construction and functions of each individual part, you can approach repairs with confidence. Proper identification and understanding of the equipment’s structure are key factors in keeping things running smoothly, reducing the risk of further damage, and avoiding unnecessary costs.

Understanding Equipment Components

Each machine is made up of a variety of individual elements that work together to ensure proper function. Understanding how these components interact is crucial for effective troubleshooting and maintenance. Whether you are handling a malfunction or performing routine upkeep, knowing the structure of the tool can significantly improve the process.

Key Elements of the System

Every device has its own set of key components, each serving a unique purpose. These pieces must work in sync to allow the machinery to function optimally. Engine systems, power sources, and control mechanisms are just a few examples of critical parts that must be in top condition to ensure seamless operation. Understanding their roles helps prevent unexpected failures and extends the life of the equipment.

Recognizing Common Issues

Once you are familiar with the essential components, it becomes easier to identify potential issues. Mechanical failures often arise from wear and tear or improper maintenance. Knowing which parts may be prone to damage helps in early detection, reducing the risk of major breakdowns and keeping the machinery running efficiently.

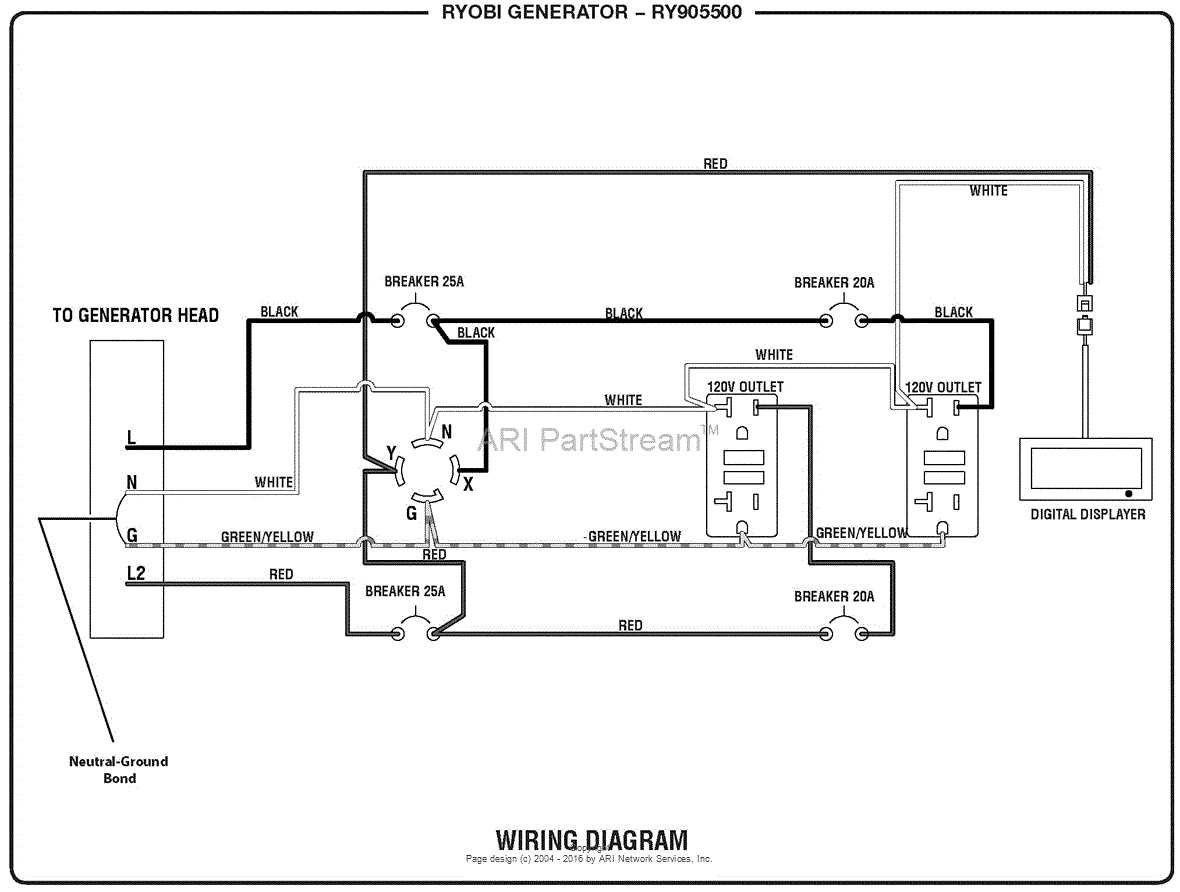

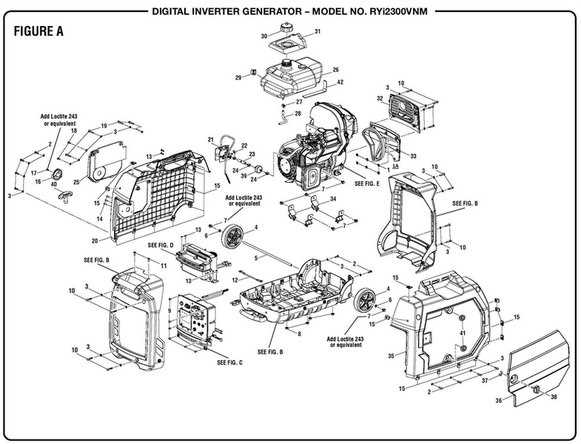

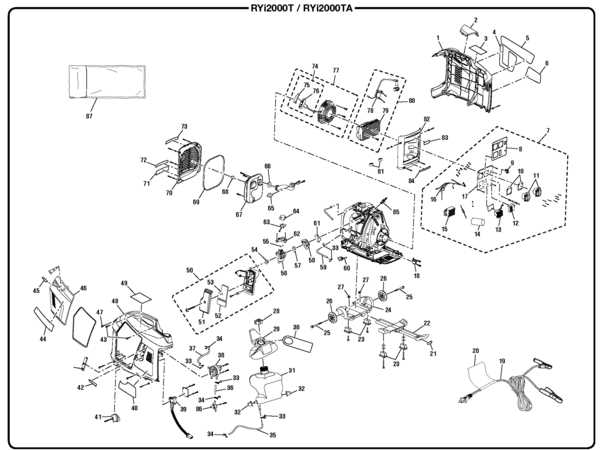

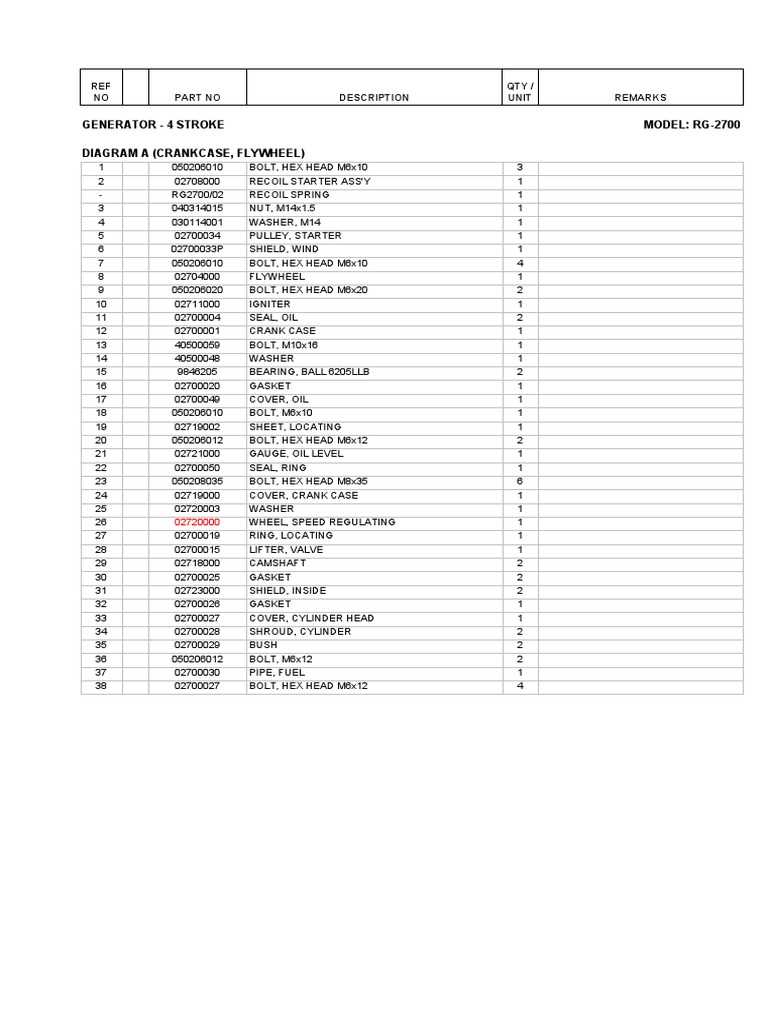

How to Read Equipment Component Illustrations

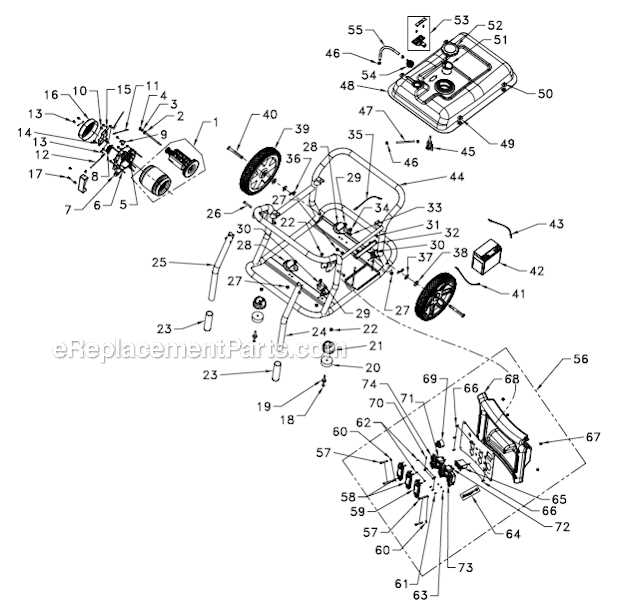

Understanding visual representations of machine elements is key to effective maintenance and repairs. These detailed images provide an organized view of how each part fits into the system. Being able to read these charts accurately allows for quick identification of components, ensuring the right repairs are made with minimal effort.

To properly interpret the illustration, start by focusing on the labels and part numbers. Each section is usually marked with clear identifiers that correspond to specific elements. These identifiers help you cross-reference with a parts list, ensuring that the correct replacements are used. Pay close attention to the orientation and positioning of each part to see how they interact with one another within the system.

Common Issues with Equipment Components

Like any machine, tools can experience problems due to wear, misuse, or inadequate maintenance. Recognizing and addressing common issues early on is essential for preventing more serious damage. Understanding where failures are likely to occur can save time and prevent unnecessary repairs.

Frequent Mechanical Failures

One of the most common issues arises from the mechanical components, which can become worn out over time. Components such as belts, shafts, and bearings are susceptible to damage from regular use. Overheating, friction, and lack of lubrication are often the causes of these failures, leading to reduced efficiency or complete breakdowns.

Electrical and Power Supply Problems

Electrical failures are another frequent issue in machinery. Damaged wiring, faulty switches, or issues with the power supply can prevent the equipment from starting or cause irregular performance. Regularly checking the electrical system and connections ensures proper functionality and can avoid costly repairs down the line.