When it comes to maintaining your outdoor equipment, understanding the internal structure is crucial for efficient repairs and replacements. Knowing where each piece fits and how it functions can help you make informed decisions about your machine’s upkeep. This guide will walk you through the essential components of your tool, ensuring you can easily navigate its assembly and troubleshooting processes.

Exploring the various parts of a tool involves not only identifying each piece but also understanding its role within the system. Proper knowledge can significantly reduce the time spent on repairs and prevent unnecessary replacements. By breaking down the essential components, you’ll gain confidence in handling issues independently.

Whether you’re a seasoned professional or a DIY enthusiast, having a clear view of the parts layout can save you both time and money. With a little guidance, even the most complex tasks become manageable. The following sections will help you understand the key components and how they interact within your machine.

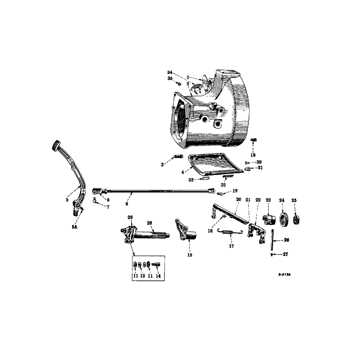

Understanding Trimmer Assembly Layout

To effectively maintain and repair your outdoor equipment, it is essential to understand how the different components are arranged and interact with each other. A clear understanding of the layout allows you to quickly identify any potential issues and address them without unnecessary disassembly. Each element plays a role in the overall function, and knowing where everything fits ensures efficient troubleshooting and maintenance.

Key Components and Their Functions

At the core of every trimmer is a collection of crucial parts that enable smooth operation. These include the motor, drive shaft, and cutting mechanisms. By recognizing each component’s specific purpose, you’ll be able to pinpoint any areas requiring attention, whether it’s the motor for performance issues or the cutting head for wear and tear. The arrangement of these elements is designed for optimal functionality, and understanding their positioning will help in troubleshooting effectively.

How to Read the Layout for Maintenance

When looking at the assembly layout, it’s important to interpret the design accurately. The layout typically shows how different parts are connected, which can help guide you in identifying the correct sequence for repairs or part replacements. Familiarity with the assembly allows you to efficiently dismantle and reassemble your equipment, ensuring that each component is correctly placed and functioning as intended.

Identifying Key Components of the Trimmer

Understanding the essential components of your outdoor tool is fundamental for proper use, maintenance, and troubleshooting. Each part has a specific role in the overall operation, from powering the machine to executing the trimming tasks. Recognizing these key components allows you to handle any issues that may arise and ensures that your tool functions at its best.

The motor is the heart of the machine, providing the necessary power to drive the mechanism. It connects to other elements, such as the drive shaft, which transmits motion to the cutting head. The cutting head itself is equipped with blades or lines designed to handle various tasks, while the housing holds everything in place and protects the internal components from damage.

Additionally, the trigger mechanism allows you to control the tool’s operation, adjusting its speed or turning it on and off. Understanding how each of these components works together will enable you to troubleshoot effectively and perform basic maintenance tasks, such as cleaning or replacing worn parts.

How to Replace Trimmer Components

Replacing worn or damaged components is an essential aspect of maintaining your outdoor equipment. By understanding the process, you can quickly restore the tool to its optimal working condition without needing professional assistance. This section will guide you through the necessary steps to replace key parts, ensuring a smooth and efficient repair process.

Start by powering off the tool and disconnecting it from any power source. This is crucial for your safety before beginning any disassembly. Next, carefully remove the protective housing to access the internal parts. Be sure to keep track of any screws or fasteners you remove, as they will be needed when reassembling the tool.

After exposing the components, identify the part that needs replacing–whether it’s the motor, drive shaft, or cutting mechanism. Remove the faulty part by loosening or detaching it from its housing. Once the new component is in place, carefully reassemble the tool, ensuring everything is properly aligned. Finally, check that the tool is functioning correctly before using it again.