When maintaining complex machinery, understanding how individual elements fit together is crucial for ensuring efficiency and longevity. This section provides a detailed overview of how to visualize and identify different parts of a machine for easier maintenance, repair, and overall functionality. Whether you’re a technician or an operator, knowing how to navigate these reference tools can save time and effort in the long run.

Key Elements of the Machine

Machines consist of numerous interconnected pieces that work together to perform specific tasks. By understanding each element’s role, it becomes easier to troubleshoot issues and replace worn-out parts. These elements include mechanical, electrical, and operational components that need to be well-maintained for smooth operation.

Mechanical Components

- Engines

- Transmission systems

- Bearings and gears

Electrical Systems

- Wiring and circuitry

- Motors and sensors

- Control panels

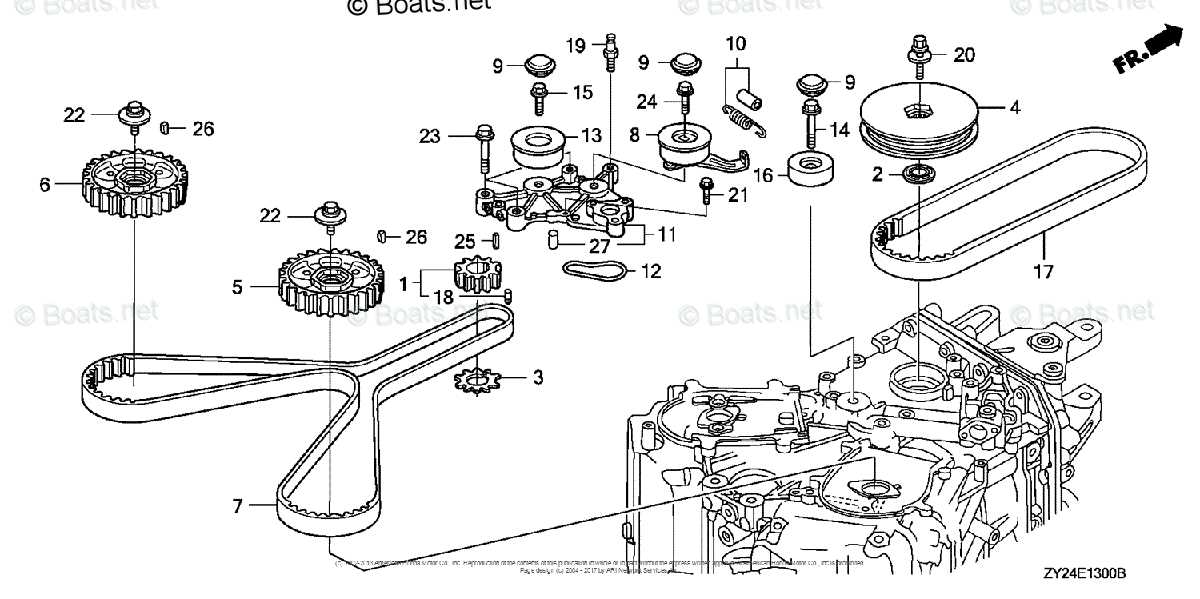

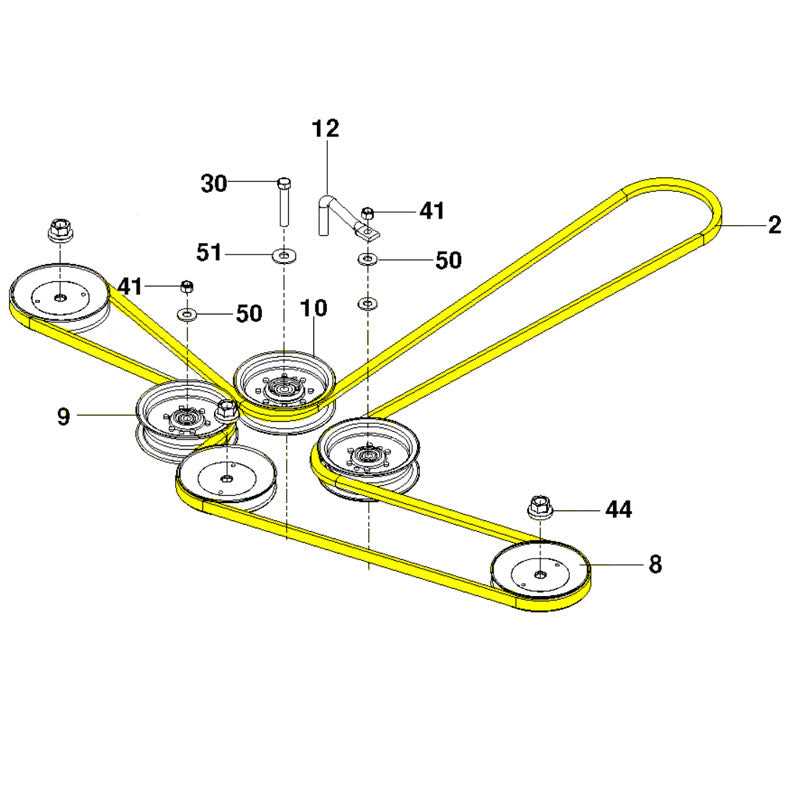

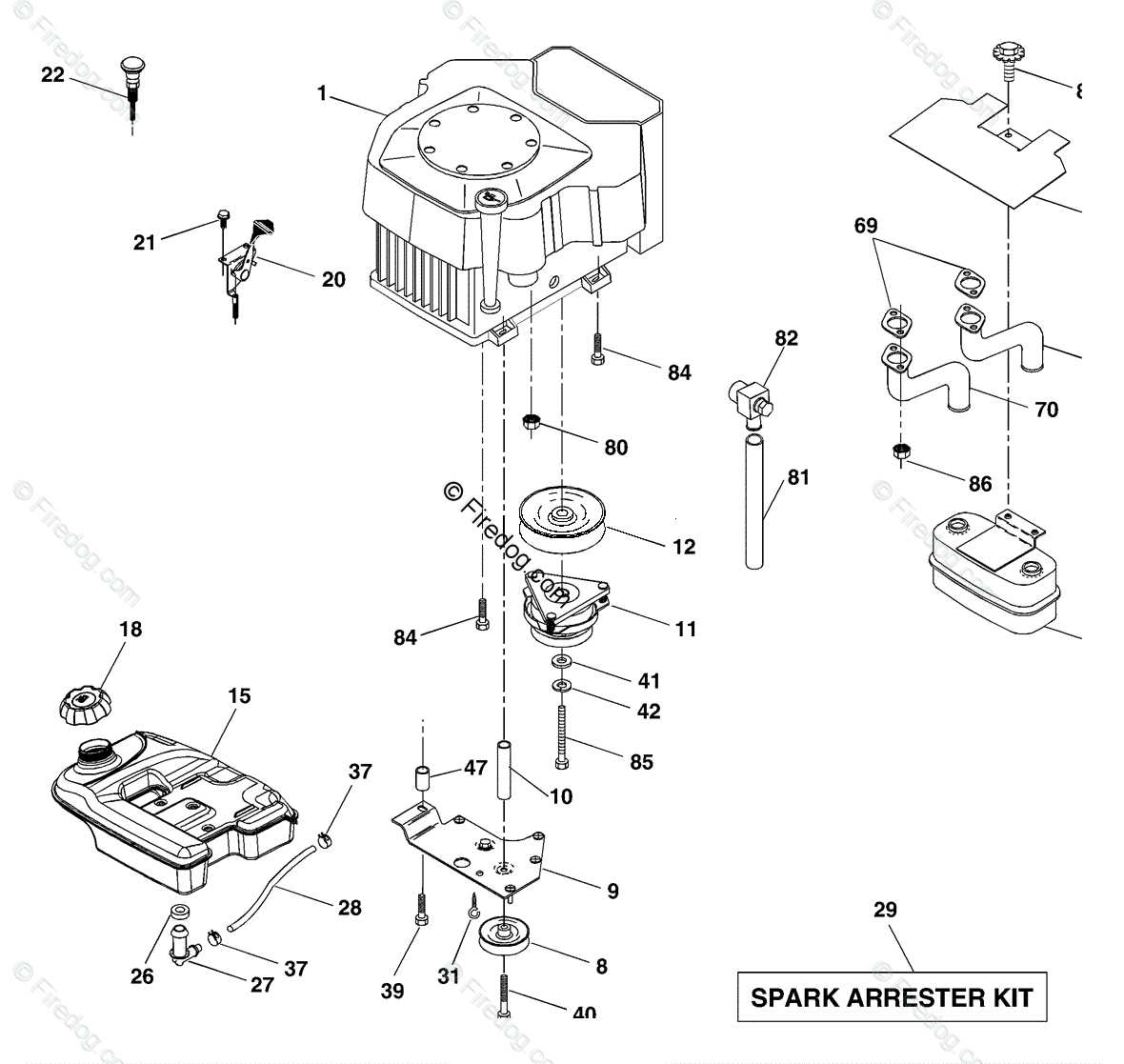

Interpreting the Breakdown

Properly reading the machine breakdown allows technicians to identify the location and specifications of each part. This helps when assembling, disassembling, or replacing components. Clear visuals provide the most accurate representation of how each piece functions within the system, ensuring repairs are done correctly the first time.

Step-by-Step Identification

By following an organized reference, each part’s purpose and placement become more understandable. This step-by-step guide ensures that no component is overlooked, allowing for quick identification and easy replacement.

Benefits of Accurate Component References

Having a clear and accurate visual representation of machine elements offers several advantages. It helps reduce errors, enhances repair efficiency, and minimizes downtime. Knowing the exact location of a malfunctioning component leads to faster fixes and improved overall performance of the machine.

Understanding the Breakdown of Machine Components

Properly understanding how machinery is assembled and functions is essential for maintaining operational efficiency. This section will guide you through the key elements of the machine, how to interpret its internal layout, and the benefits of having clear references for repairs and maintenance. Knowing how to navigate these resources can significantly improve repair accuracy and save time during troubleshooting.

Key Elements of the Machine Model

The structure of any complex machine consists of various crucial components, each serving a specific function. These parts work together to ensure optimal performance, and knowing their roles helps in better maintaining and diagnosing the system. Understanding their interconnection is vital for efficient troubleshooting and part replacement.

How to Read the Internal Layout

Understanding the internal structure starts with learning how to read and interpret the layout guide. This provides a visual map of the components and their placements, allowing technicians to quickly find the necessary parts during maintenance. A clear and accurate layout can significantly reduce repair time and prevent errors.

Step-by-Step Guide to Identifying Components

A step-by-step approach is key when attempting to identify and replace machine components. By following an organized system, you can locate the exact part in need of attention, avoiding unnecessary disassembly and ensuring that only the malfunctioning parts are targeted. This methodical approach saves both time and resources.

Importance of Accurate Component References

Clear and precise references are essential in machine maintenance. They enable technicians to locate parts quickly, identify problems, and complete repairs efficiently. Accurate component guides contribute to smoother operations, reduce the risk of mistakes, and ultimately extend the lifespan of the machinery.