When maintaining mechanical devices, it is essential to have a clear understanding of their structure and individual elements. Whether you’re performing routine maintenance or troubleshooting issues, knowing the different components and how they interact is crucial for efficient operation. This knowledge not only helps in identifying potential problems but also ensures proper repair and upkeep.

Being able to interpret the layout and organization of your device’s key features can save you time and effort. From identifying worn-out components to ensuring optimal performance, a comprehensive guide can be a valuable resource for both beginners and experienced users. By familiarizing yourself with the system, you’ll have a clearer view of how everything fits together and functions in harmony.

Effective maintenance starts with understanding the mechanical flow, identifying which parts need attention, and ensuring everything works as intended. In the following sections, we will explore how to identify common issues and how to address them efficiently, using clear and accessible information about the internal structure of your machinery.

Understanding the Internal Components

Every mechanical system is made up of various interconnected parts that work together to ensure smooth operation. Knowing the individual elements and their functions is essential for anyone looking to maintain or repair such equipment. This section will break down the critical components, providing a clear understanding of how each piece contributes to the overall performance of the machine.

Key Elements of the System

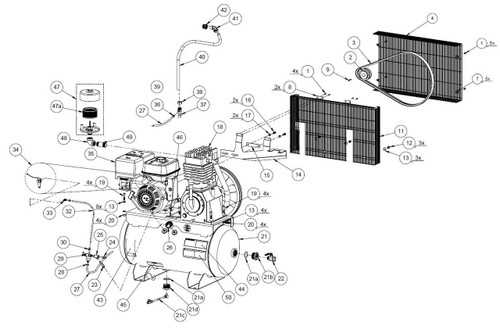

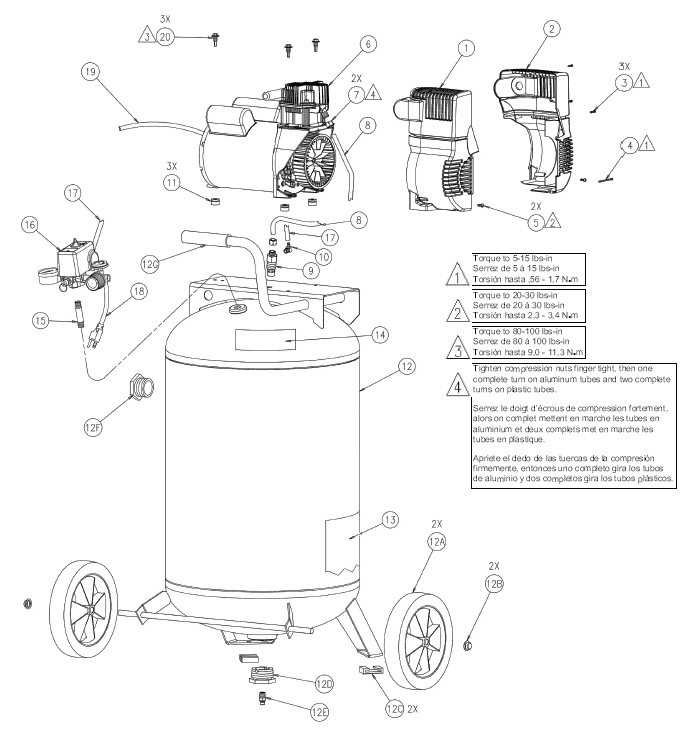

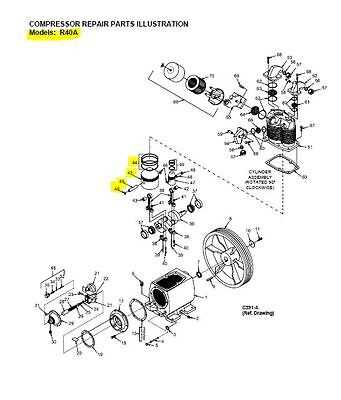

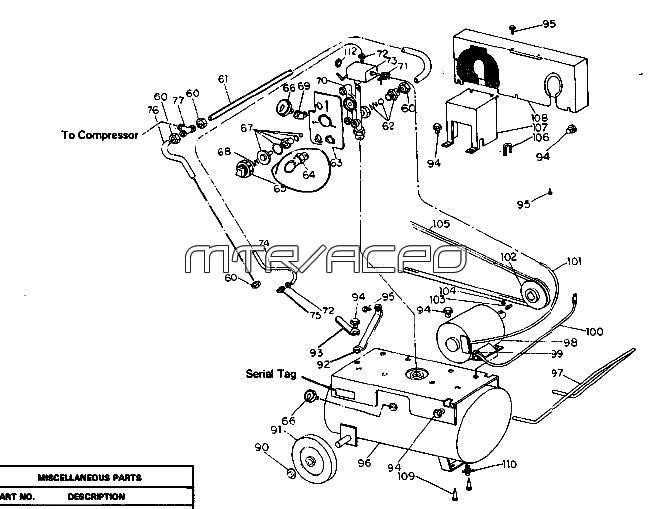

The core of any machine is its internal assembly, including moving elements like pistons, valves, and seals, as well as stationary parts like frames and pressure vessels. Each component has a specific role in the operation process, whether it’s regulating airflow or maintaining pressure. By familiarizing yourself with the function of each part, it becomes easier to identify potential issues and perform necessary maintenance.

Maintaining System Efficiency

Proper maintenance requires more than just replacing faulty parts. It involves understanding the system’s inner workings and ensuring that each component operates within the optimal range. Regular checks, lubrication, and cleaning can prolong the life of individual pieces and keep the machine running smoothly. Preventive care is crucial to avoid costly repairs and ensure maximum efficiency.

How to Read a Parts Diagram

Understanding technical illustrations of mechanical systems is an essential skill for anyone performing repairs or maintenance. These visual representations break down the assembly into individual elements, allowing you to see the exact layout and connection between components. A clear guide helps you identify each piece and its role within the entire mechanism, making it easier to troubleshoot or replace parts as needed.

To effectively interpret such a guide, start by recognizing the labeling system used for each part. Usually, each component is assigned a number or letter, which corresponds to a detailed list or catalog. This list provides additional information about size, material, and function, helping you confirm that you’re working with the correct parts. Pay attention to lines and arrows indicating how elements are connected, as this will give you a better understanding of the flow and operation of the system.

Common Issues with Compressing Equipment

Even the most reliable machinery can experience problems over time. Identifying common faults early can prevent more serious damage and costly repairs. Understanding the typical issues that arise in mechanical systems can help you troubleshoot effectively and perform timely maintenance to keep the equipment running smoothly.

One frequent problem is improper pressure regulation, often caused by worn-out valves or seals. This can result in either insufficient or excessive pressure, affecting the machine’s overall performance. Another common issue is overheating, which may be the result of inadequate cooling or excessive use without breaks. Regularly checking for any blockages or air flow restrictions can help maintain optimal performance and avoid these complications.