Maintaining a functional onboard waste management system is essential for a smooth sailing experience. Knowing the layout and function of each component allows for easier troubleshooting and repair. A comprehensive understanding of these systems can save time, reduce costs, and ensure your equipment remains in optimal condition.

Efficient maintenance starts with being familiar with each part’s role. Whether you’re dealing with blockages, leaks, or a malfunctioning flush, a clear visual map of the system can guide you through identifying the issue.

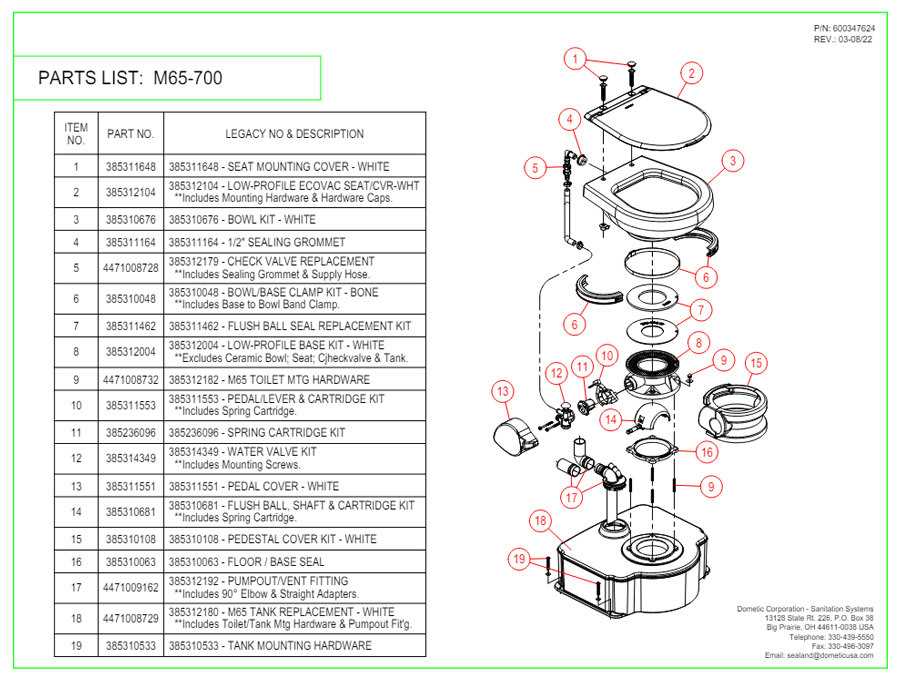

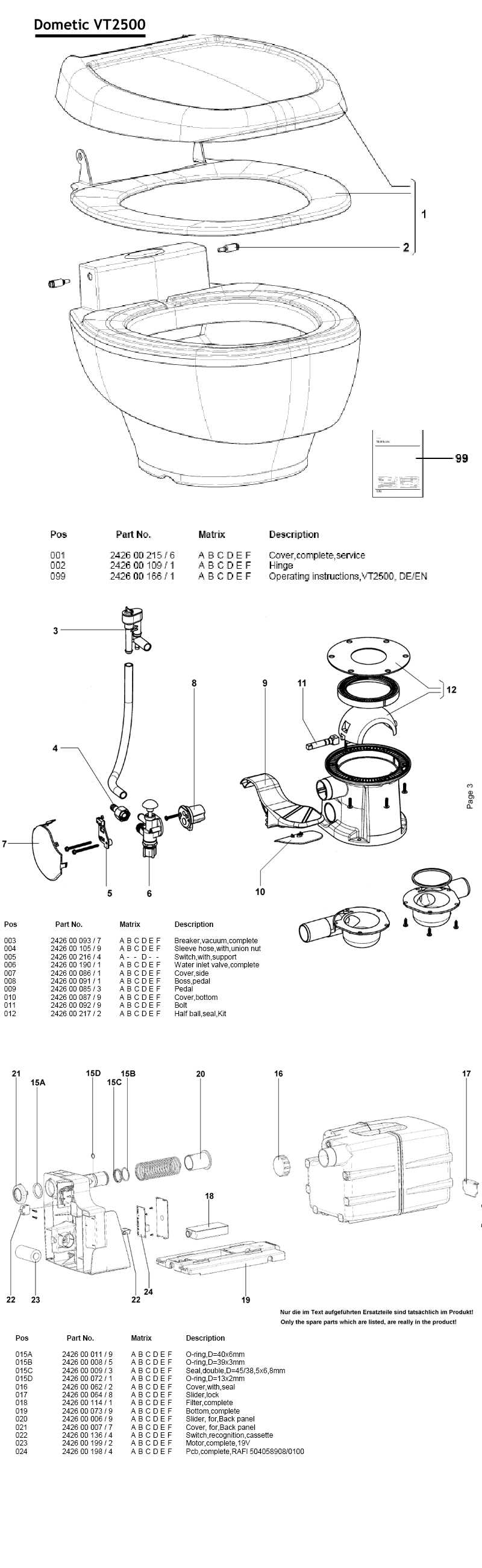

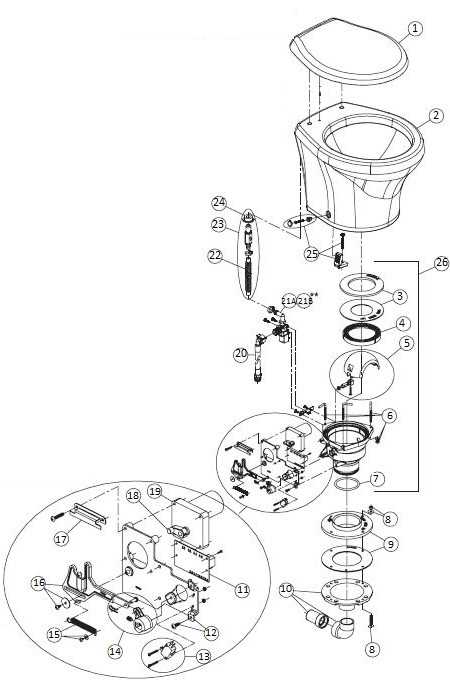

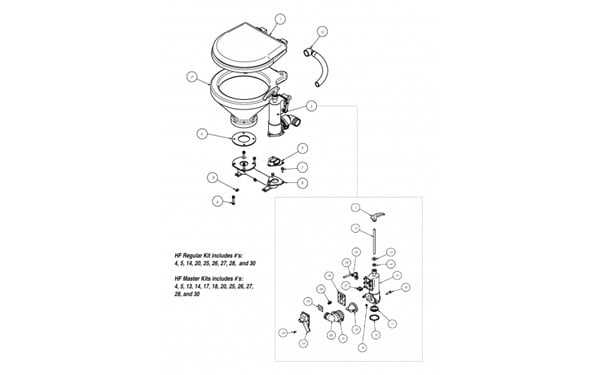

Identifying each component and knowing its purpose within the overall system is critical for both regular upkeep and emergency fixes. This knowledge not only helps with repairs but also enables better-informed decisions on replacements and upgrades.

Understanding Marine Sanitation System Components

Each element of a marine waste system plays a crucial role in ensuring smooth operation. Understanding the function and relationship between these components can make troubleshooting and maintenance much easier. Identifying each component helps you respond quickly to problems, whether it’s a clog, a leak, or a malfunctioning feature.

The key components of such a system typically include:

- Pump: Moves waste through the system, often powered by a manual lever or electric motor.

- Valve: Controls the flow of waste, regulating the release into holding tanks or overboard.

- Hoses: Connect the various parts and allow waste to travel from one area to another.

- Holding tank: Stores waste until it can be properly disposed of or pumped out.

- Flush mechanism: Clears waste from the bowl and sends it through the system.

Familiarity with these components helps ensure proper maintenance, reduces the likelihood of costly repairs, and extends the life of your equipment. Regular inspection and cleaning can prevent common issues that might otherwise disrupt the system’s functionality.

When each element is understood, maintenance tasks become more straightforward. Regular upkeep can range from checking the pump’s operation to ensuring the hoses are securely connected and free from blockages. This proactive approach will keep your onboard sanitation system working at its best, providing comfort and reliability throughout your journey.

Common Issues with Marine Sanitation System Components

When operating a marine waste management system, various issues may arise, leading to malfunction or inefficiency. Identifying these problems early can prevent major failures and ensure proper functioning. Common challenges often involve clogs, leaks, or mechanical failures that disrupt normal operations.

Clogs and Blockages

One of the most frequent issues is blockages in the pipes or valves. These can occur due to debris buildup, improper usage, or long periods of inactivity. Regular maintenance and careful attention to the materials being disposed of can help avoid these problems.

- Clogged pump: Waste and debris may obstruct the pump, causing it to malfunction or fail entirely.

- Blocked hoses: Obstructions in the hoses can prevent waste from flowing properly, often causing backflow or slow flushing.

Leaks and Seal Failures

Leaks are another common problem, typically caused by worn-out seals or damaged components. These leaks can lead to odors, water damage, or even environmental hazards. Identifying and replacing faulty seals promptly is essential to maintaining system integrity.

- Damaged valves: Faulty valves may cause leaks, resulting in waste leakage or improper waste release.

- Cracked tanks: A broken or cracked holding tank can cause waste to leak into the boat’s interior or into the environment.

By staying vigilant and performing routine checks, you can prevent many of these common issues from escalating. Early detection and intervention are key to ensuring the smooth and efficient operation of your onboard sanitation system.

Step-by-Step Guide to Marine Sanitation System Repairs

Repairing onboard waste management systems doesn’t have to be daunting. With a clear, step-by-step approach, most issues can be identified and fixed quickly, allowing you to return to your journey with minimal downtime. This guide provides a simple method to tackle common system problems, from clogs to leaks, ensuring that your equipment stays in working order.

Follow these basic steps for a straightforward repair process:

- Step 1: Identify the Problem – The first step is always to diagnose the issue. Whether it’s a blockage, leak, or mechanical failure, pinpointing the exact problem will help you focus on the right repair.

- Step 2: Gather Tools and Materials – Once the issue is identified, gather the necessary tools and replacement components. Common tools include wrenches, screwdrivers, and sealants.

- Step 3: Turn Off the System – Before making any repairs, always shut off the system to prevent accidents or further damage. This may involve cutting power or closing valves.

- Step 4: Fix the Issue – Based on the problem, either clear the blockage, replace a worn part, or repair a damaged component. For example, use a plunger for small clogs, or replace a broken valve seal if you’re dealing with a leak.

- Step 5: Test the System – Once the repair is made, turn the system back on and test for functionality. Ensure everything is working as expected and that no further issues remain.

With these steps, you’ll be able to address many common issues with your sanitation system. Regular maintenance and timely repairs can prevent major malfunctions and extend the lifespan of your equipment, helping you avoid costly replacements or professional service calls.