Proper maintenance of outdoor equipment requires a clear understanding of its internal structure and the roles of its various components. This knowledge ensures efficient repairs and long-lasting performance.

Being able to identify each element and its function helps users troubleshoot common issues and make informed decisions when replacing or repairing parts. With a clear reference to guide you, it becomes easier to manage your machine’s upkeep.

Whether you are a novice or experienced in equipment repair, familiarizing yourself with the mechanical details is key to enhancing your experience. Accurate identification and careful attention to each component’s specifications can save both time and effort in the long run.

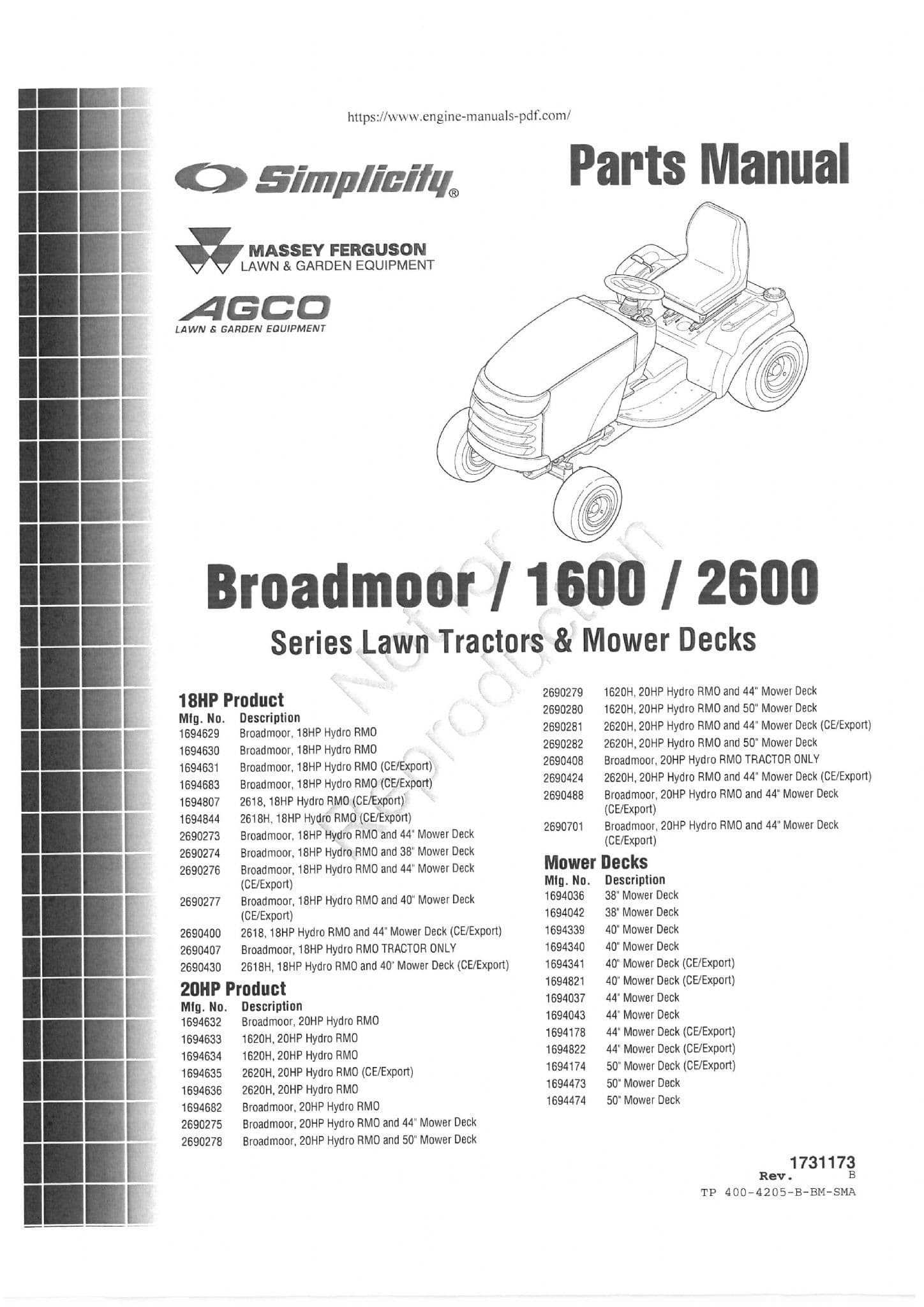

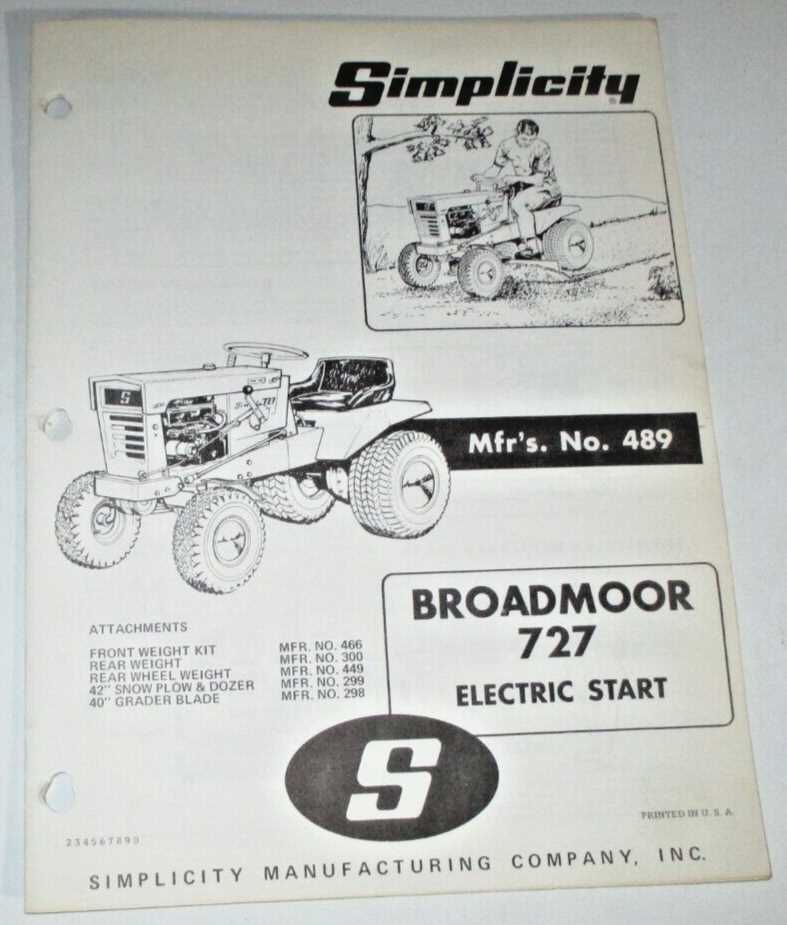

Understanding Simplicity Broadmoor Parts

To ensure the longevity and efficient operation of any mechanical equipment, it’s crucial to understand how its different components work together. This knowledge allows for more accurate troubleshooting, better maintenance, and easier replacement when parts wear out or break down.

Key Components and Their Functions

The internal structure of the machine consists of various elements, each serving a distinct purpose. Understanding how these components interact with one another helps identify potential issues and provides insight into how the system functions as a whole. Knowing which parts are essential for the machine’s operation ensures that you can address problems effectively and avoid unnecessary repairs.

Common Issues and Troubleshooting

Familiarity with the system’s components also aids in recognizing common issues, such as wear and tear, malfunctions, or broken connections. By understanding which parts are prone to damage, you can anticipate failures before they disrupt performance and plan accordingly for replacements.

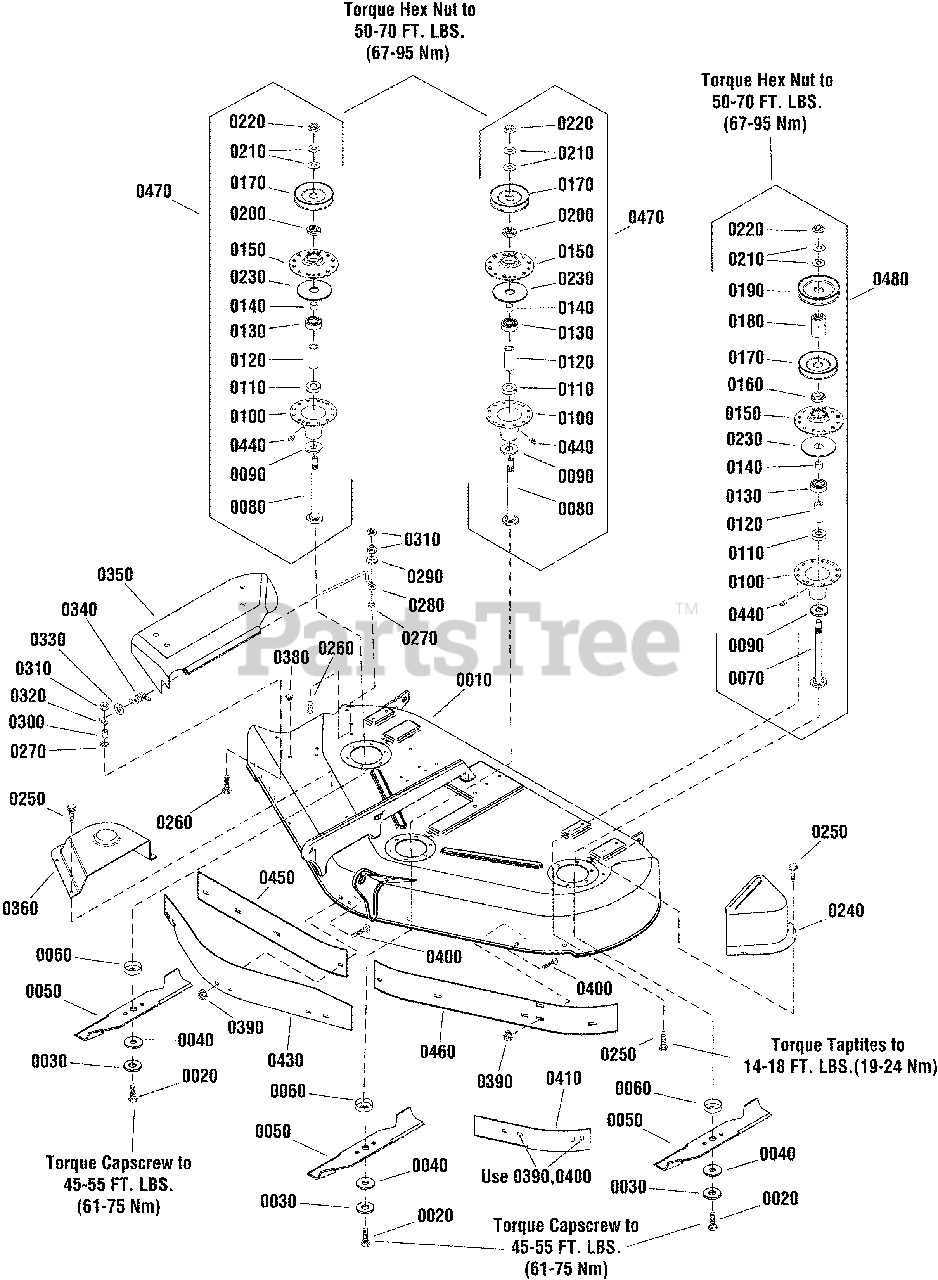

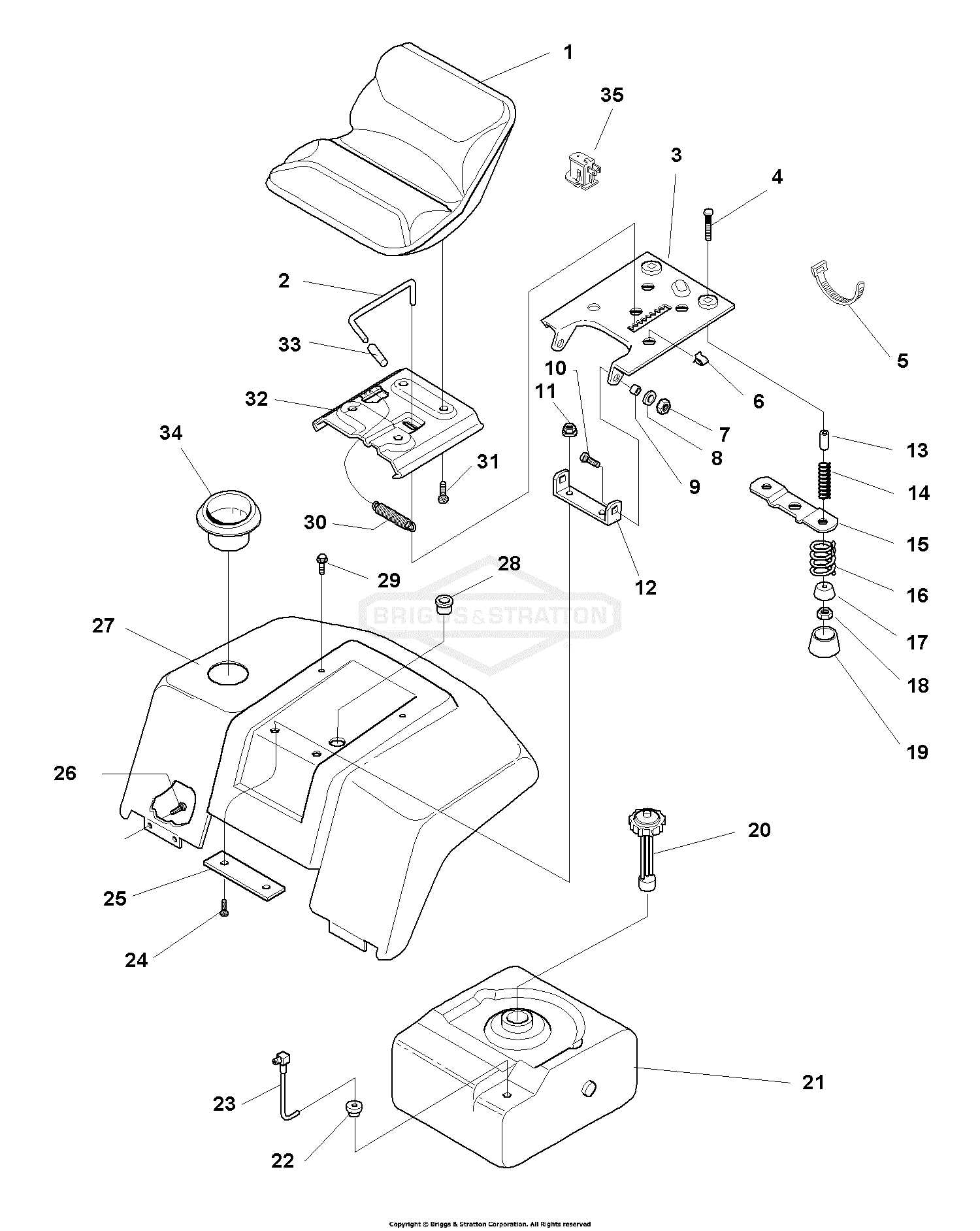

How to Read the Parts Diagram

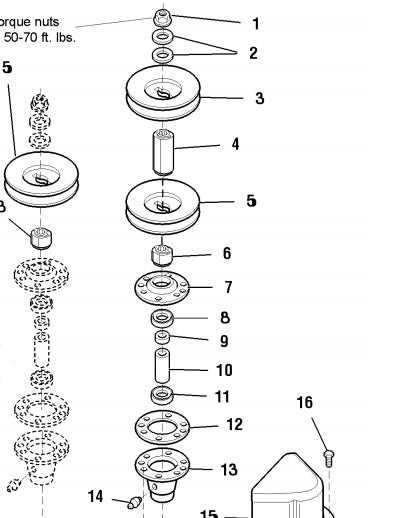

Understanding how to interpret a visual representation of a machine’s components is essential for effective repairs and maintenance. These illustrations provide a detailed view of how different parts are arranged and how they interact with one another, offering valuable insights for users and technicians alike.

Identifying Components and Their Placement

Each component is marked with a unique identifier, allowing you to locate it within the system. By following the visual cues, you can match the component’s number or label to its corresponding part in the machine. This helps ensure that every element is properly understood and addressed when needed.

Understanding Connection Points and Functionality

In addition to identifying individual components, it’s also crucial to recognize how they are connected. Understanding how parts interact with one another helps in diagnosing issues related to wear, stress, or improper assembly. This knowledge allows for more accurate troubleshooting and efficient repair processes.

Common Issues and Replacements for Parts

Over time, machines can experience wear and tear that affects their performance. Understanding the most common problems and knowing how to replace the faulty components can save time and prevent further damage. Identifying these issues early ensures that the equipment continues to function smoothly.

Frequent Mechanical Failures

Some of the most common issues involve mechanical components that wear out due to regular use. These failures often manifest as unusual sounds, reduced efficiency, or a complete breakdown of specific functions. Identifying these early signs and knowing which components to inspect can help prevent more serious damage.

Replacing Worn-Out Components

When parts show signs of wear or failure, it’s crucial to replace them promptly. Common replacements include worn belts, damaged bearings, or faulty connectors. Knowing the exact part number and specifications makes the replacement process faster and ensures compatibility with the rest of the system.