Proper maintenance of your outdoor machinery requires an understanding of its internal elements. Whether you’re working with a tool for clearing paths or handling heavier snow removal tasks, recognizing each component’s role ensures efficient operation and long-term reliability.

With clear knowledge of the individual sections that make up the machine, identifying wear and tear becomes simpler. This can help prevent common issues and guide you through repair procedures when necessary. Knowing the key parts allows for quicker troubleshooting, saving time and effort during the colder months.

When dealing with any mechanical equipment, familiarizing yourself with how it’s built and how each segment interacts is essential. This understanding can increase the lifespan of your machine, improve its performance, and offer you peace of mind throughout its usage season. Investing time in learning about the components is a crucial step in taking care of your gear.

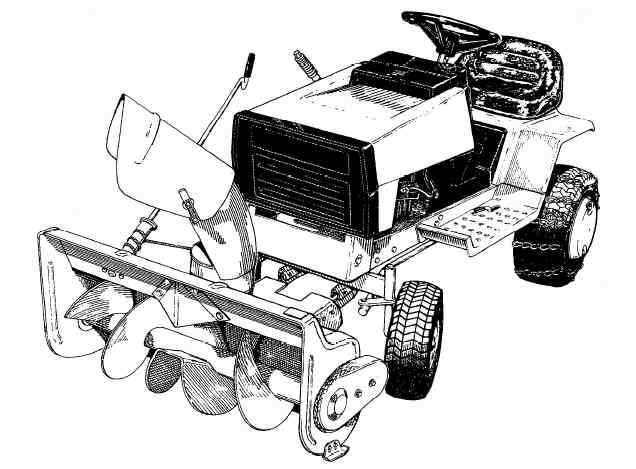

Understanding the Simplicity Snowblower Parts

Every machine designed for clearing heavy snow relies on several key components that work together to ensure smooth operation. Familiarizing yourself with these crucial elements can enhance your ability to maintain the equipment and resolve issues efficiently. By understanding the structure and function of each part, you ensure better performance and longevity.

Key Functional Components

The main elements of your equipment include the drive system, chute, and auger assembly. The drive system powers the machinery, enabling it to move forward and clear large areas effectively. The auger assembly is responsible for breaking up snow and directing it toward the chute, while the chute determines the direction in which the snow is thrown. Understanding how these systems interact is vital for both troubleshooting and routine maintenance.

Maintaining Each Element

Regular inspection and upkeep of these components can prevent wear and tear. The drive system requires periodic lubrication to ensure smooth movement, while the auger blades should be checked for sharpness and damage. Additionally, the chute must be cleared of any ice build-up to prevent clogging and ensure proper snow discharge. A proactive approach to maintenance can significantly extend the life of your machine.

Identifying Key Components in Your Snowblower

Understanding the essential elements that make up your snow-clearing machine is the first step towards ensuring its optimal performance. Recognizing how each part functions within the overall system will help you troubleshoot issues and perform necessary repairs. By becoming familiar with the primary components, you can take better care of your equipment and address potential problems before they escalate.

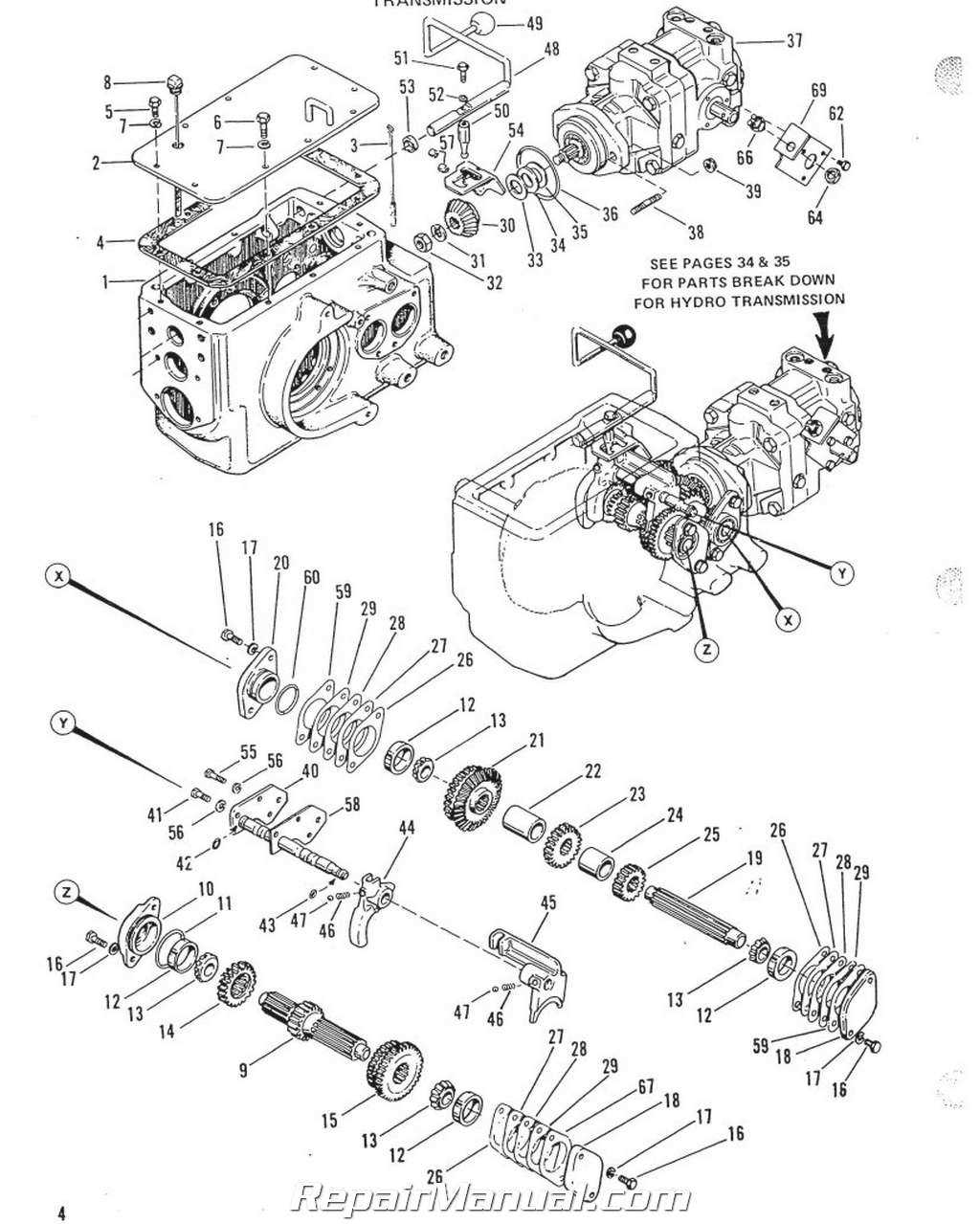

Essential Mechanical Elements

The drive mechanism is at the core of your equipment, enabling movement and propulsion. This system includes the engine, transmission, and wheels or tracks, which work in unison to power the machine forward. Additionally, the auger assembly plays a crucial role in gathering and moving snow, while the discharge chute directs the snow to the desired location. Understanding how these parts interact helps ensure smoother operation and easier troubleshooting.

Visual Clues for Identifying Components

Many components of your machine will show visual signs of wear, especially after extended use. For instance, check for any physical damage or signs of corrosion on the auger blades, as this may affect their efficiency. Also, pay attention to the belt system that drives the machinery. Regular inspections will allow you to spot worn-out parts early and prevent larger issues that may require costly repairs.

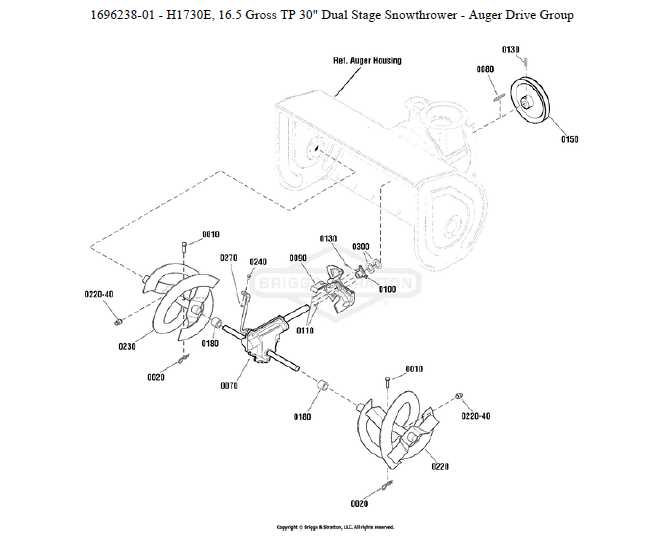

Common Maintenance Tips for Snowblower Parts

Regular maintenance is key to keeping your snow-clearing machine in top condition. By following simple upkeep practices, you can prevent unexpected breakdowns and extend the life of your equipment. Ensuring each component functions properly helps you get the most out of your investment and keeps the machine running smoothly during the harshest conditions.

Start with routine checks of the drive system, especially focusing on the belts and cables. Ensuring that these elements are free from wear and properly tensioned will avoid performance issues. Next, inspect the auger and discharge chute for any signs of damage or ice buildup, which can block movement and reduce efficiency. Lubricating moving parts such as wheels and auger shafts also ensures smooth operation and reduces friction-related wear.

Lastly, ensure the fuel system is functioning correctly by checking for leaks and replacing old fuel when necessary. Maintaining clean filters and inspecting the air intake will allow the engine to run more efficiently, while also reducing harmful emissions. Taking the time to regularly clean and service your equipment will make a significant difference in its performance and lifespan.