Maintaining and repairing a sewing machine requires a clear understanding of its internal mechanisms. Recognizing each element’s function and location is crucial for smooth operation. Whether you’re troubleshooting issues or performing regular maintenance, knowing the setup of key components can significantly simplify the process.

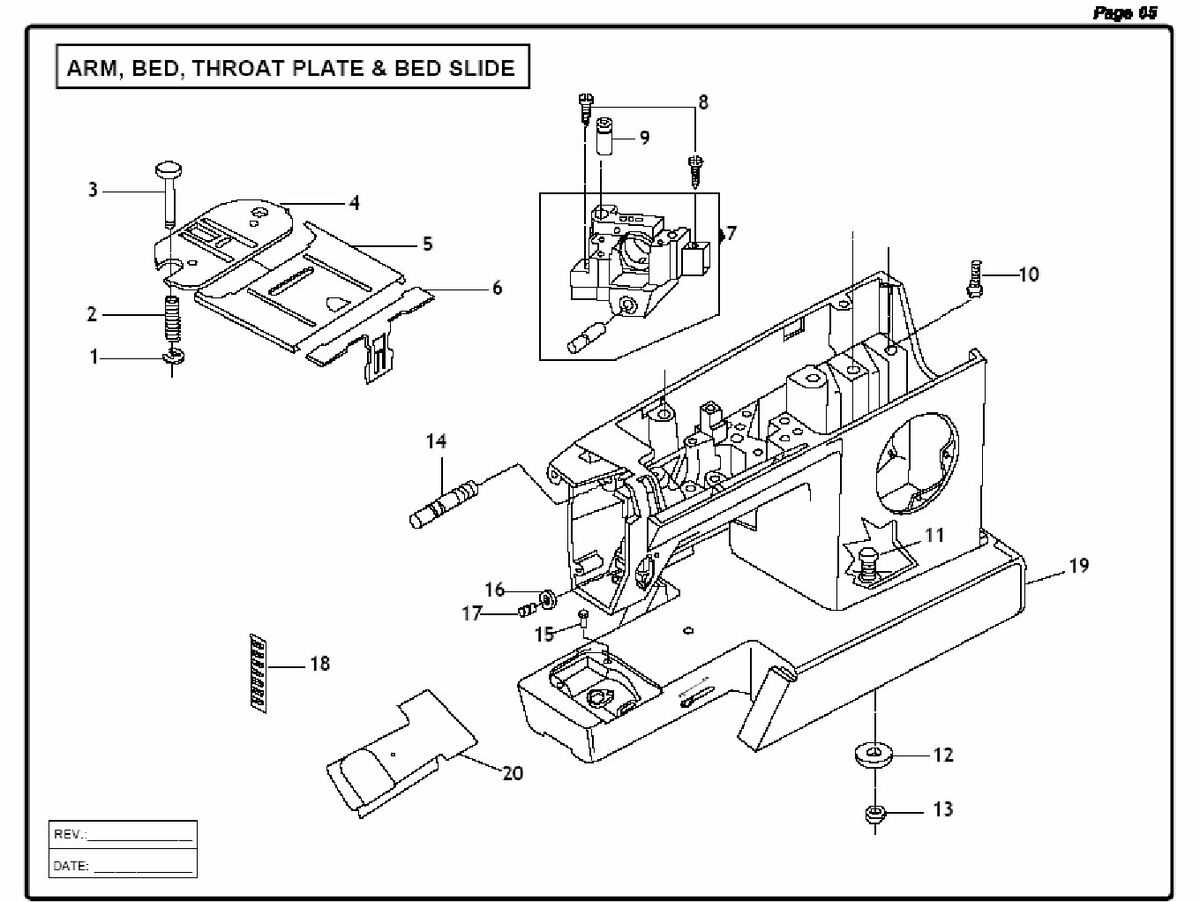

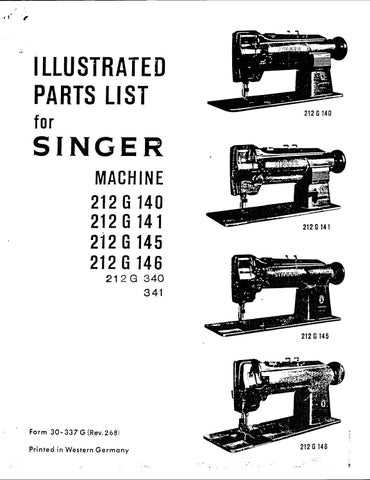

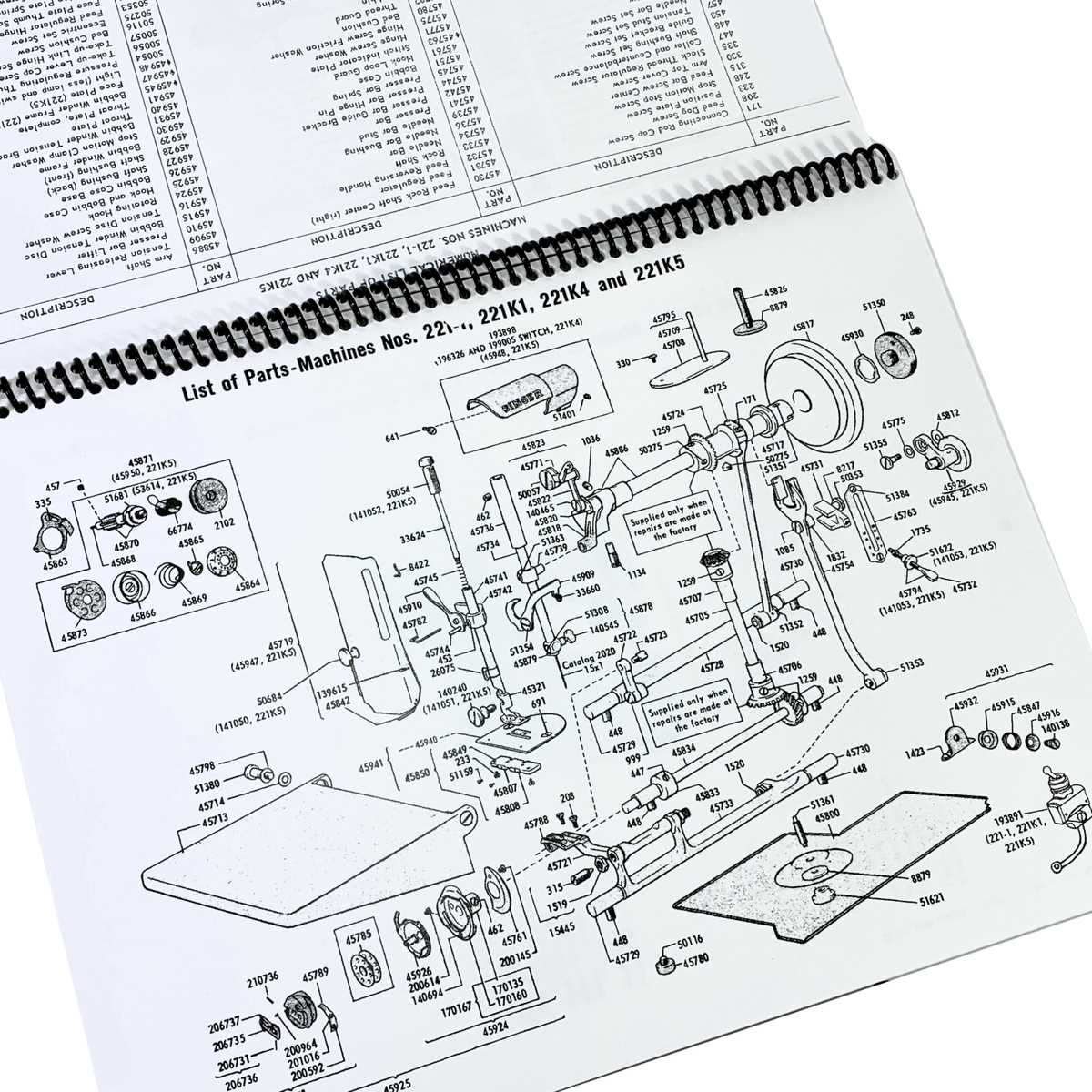

Detailed visuals and clear labeling help users identify each part easily, making repairs less intimidating. By examining these images closely, you gain the ability to pinpoint malfunctions and solve them efficiently without unnecessary confusion. This knowledge also empowers you to perform routine upkeep with confidence.

In the following sections, we will delve into how understanding the various components can enhance both your repair skills and overall sewing experience. Understanding each element’s role ensures the longevity of your machine and improves your proficiency in using it.

Understanding the Key Sewing Machine Components

Every sewing machine consists of several integral elements that work together to create smooth, efficient operation. Recognizing these components and their specific functions helps users diagnose problems and ensure proper maintenance. From the motor to the needle, each part plays a critical role in the machine’s overall performance.

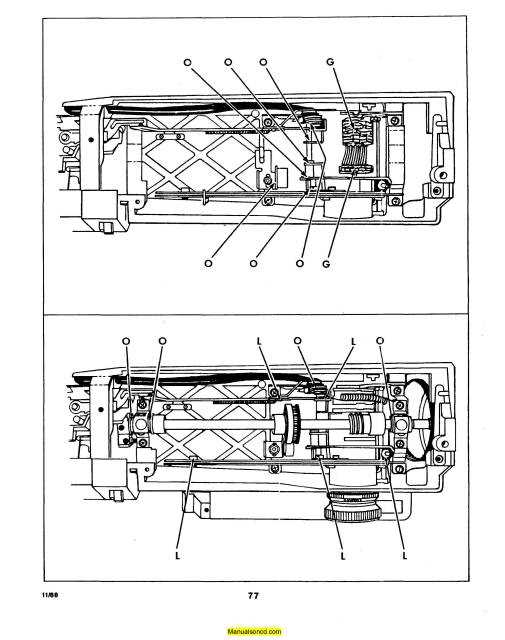

The machine’s main structure includes a framework that supports moving parts, allowing smooth motion during sewing. The feed mechanism, responsible for moving the fabric through the machine, works in tandem with the needle and thread system to ensure consistent stitching. Additionally, the tension control system adjusts the thread tightness to guarantee perfect seams.

Other important components, such as the bobbin assembly, balance the thread tension and prevent jams, while the presser foot keeps the fabric in place during sewing. Understanding the function of each element ensures you can effectively troubleshoot and maintain your equipment, leading to more successful sewing projects.

How to Use a Sewing Machine Component Guide Effectively

Understanding a machine’s layout and its components can make repairs and maintenance significantly easier. A well-detailed reference guide provides clear visuals and labels to help users identify parts, ensuring that you can troubleshoot, replace, or adjust parts with accuracy. This reference becomes an essential tool for any sewing machine owner, from beginners to advanced users.

Identifying Key Components

Before using the guide, familiarize yourself with the most commonly used sections of your machine. Pay attention to the moving parts, such as the needle system and feed mechanism, as well as the fixed components that support its operation. By learning the general layout, you will be able to quickly spot the components when you need to make adjustments or fix issues.

Step-by-Step Troubleshooting

Using the guide step by step is the most effective approach for solving problems. Begin by isolating the area of concern and comparing it to the corresponding section in the guide. This allows you to determine if a part is out of place, worn, or malfunctioning. With this visual aid, you can work through the issue methodically, reducing the chances of mistakes and ensuring a faster resolution.

Common Issues and Solutions for Sewing Machines

As with any complex machinery, sewing machines can experience a variety of common problems over time. Identifying the issue quickly is key to fixing it efficiently. Whether it’s uneven stitching, thread jams, or mechanical malfunctions, recognizing the root cause can save time and prevent further damage.

One frequent issue is the needle not picking up the bobbin thread, which can often be resolved by checking the needle’s position or ensuring that both the needle and bobbin are threaded correctly. Another common problem is skipped stitches, which might be caused by incorrect needle size or tension settings. Ensuring these elements are set according to fabric type can prevent this problem from recurring.

Additionally, thread jams are another typical problem. If the fabric is not feeding correctly or there are thread tangles, it could be due to improper tension or a clogged feed system. Regular cleaning and proper thread installation can often solve this issue. By addressing these common concerns and using the right maintenance practices, many issues can be resolved without the need for professional repair.