Proper maintenance of farming machinery relies on a clear understanding of its individual elements and how they function together. Recognizing the key components of any machine is essential for efficient operation and long-lasting performance.

Efficient farming equipment often consists of a range of interconnected pieces, each designed to contribute to the overall success of agricultural tasks. Knowing the layout and function of these elements can prevent costly repairs and ensure that the equipment performs at its best.

By learning to identify the components and their roles, users can enhance their ability to troubleshoot issues, perform necessary adjustments, and replace worn parts when needed. With this knowledge, the machinery can continue to operate smoothly, even under demanding conditions.

Sitrex Hay Rake Parts Overview

Understanding the key elements of a farming tool is crucial for ensuring its optimal function. This section provides an overview of the main components found in such equipment, highlighting their roles and importance in achieving efficient operation.

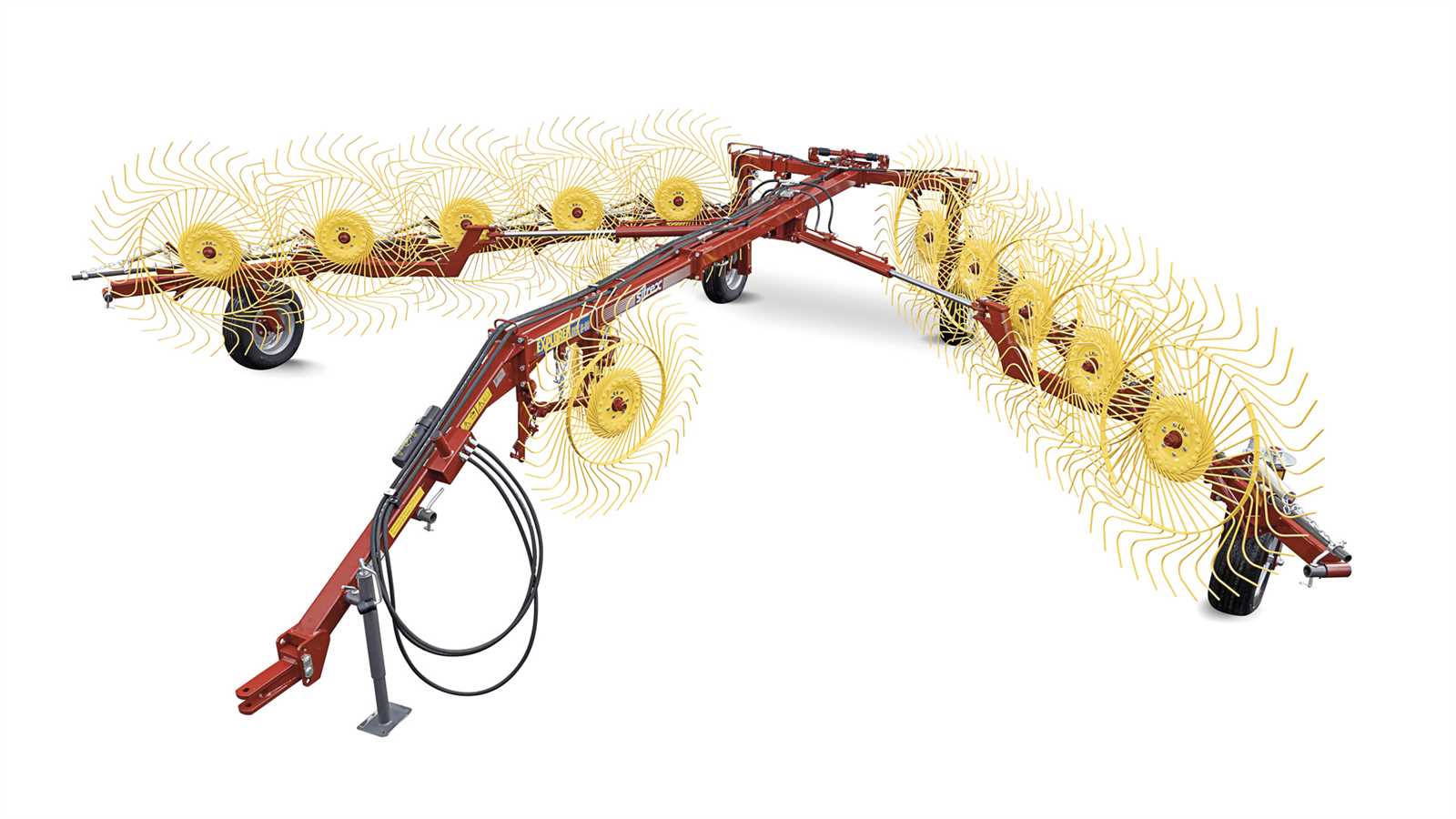

Main Structural Components

The frame serves as the foundation of the machine, supporting all other elements. It is designed to endure the stresses of agricultural work, providing stability and durability. Attached to the frame are various moving parts that are responsible for gathering and redistributing materials.

Key Moving Mechanisms

Moving parts, such as gears and wheels, are vital for the machine’s functionality. These mechanisms work in unison to control the movement of the tool and allow it to perform tasks with precision. Regular inspection of these components ensures smooth performance and helps avoid breakdowns.

Understanding the Key Components

Farming tools are composed of various essential elements that work together to ensure the machine operates efficiently. Each component plays a specific role in performing the necessary functions, contributing to the overall success of agricultural tasks.

The main elements of such equipment include both static and moving parts, each designed for durability and reliability. Understanding how these components interact can help users properly maintain their machinery, ensuring smooth operation throughout the season.

Proper knowledge of the core elements also aids in troubleshooting and identifying potential issues early, preventing costly repairs and improving the tool’s longevity.

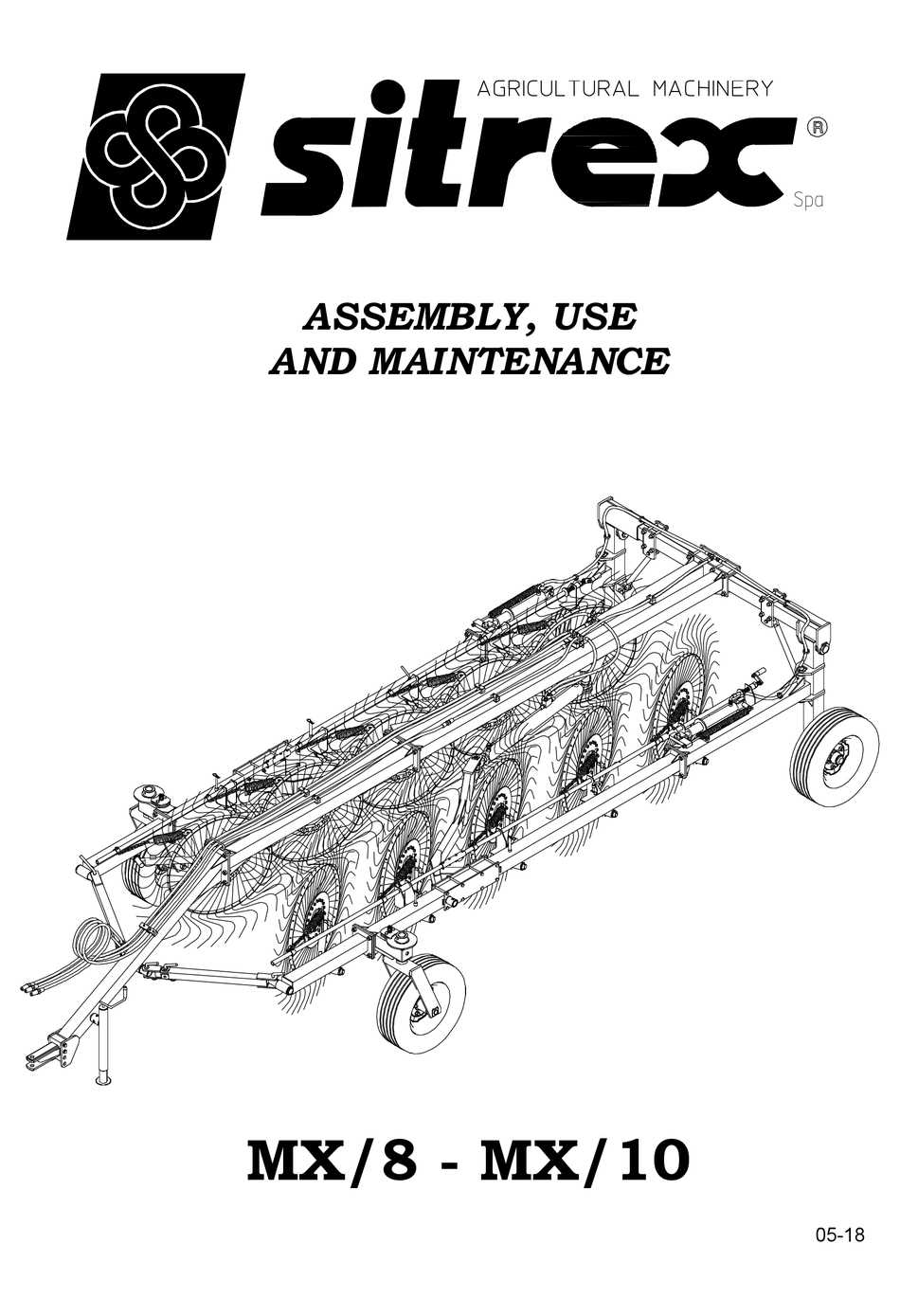

How to Read the Parts Diagram

Understanding how to interpret the layout of machine components is an essential skill for anyone maintaining or repairing agricultural tools. A visual representation of the equipment’s elements provides a clear understanding of where each part fits and how they work together to perform specific tasks.

Key Elements in the Illustration

In any technical drawing, each part is typically labeled with a reference number or name. These labels correspond to a list of components, which makes it easier to identify the right pieces when performing maintenance or replacement. Clear labeling ensures that users can quickly locate the required element without confusion.

Interpreting Connections and Functionality

Pay attention to how parts are connected in the illustration. Lines or arrows often indicate the movement or direction of action, while grouping similar elements together can help users understand their collaborative function. Recognizing these relationships will assist in troubleshooting issues and making adjustments to improve the machine’s performance.

Common Issues and Part Replacements

Even the most reliable farming equipment may experience issues over time. Identifying common malfunctions and knowing when to replace specific elements is essential for ensuring smooth operation and avoiding unnecessary downtime.

Common Issues

Various factors can contribute to equipment failure, often related to wear and tear or improper use. Below are some typical problems that may arise:

- Worn-out components: Constant use can lead to parts becoming loose or damaged, affecting overall performance.

- Misalignment: When parts are not properly aligned, it can result in inefficiency and damage to other connected elements.

- Broken moving mechanisms: Failure of gears, wheels, or other moving parts can lead to stoppages or decreased functionality.

When to Replace Components

Knowing when a part is beyond repair and needs replacement is crucial. Regular inspection is the key to detecting wear early. Here are signs that indicate it may be time to replace a part:

- Excessive wear: Parts that show visible signs of damage or excessive wear should be replaced promptly.

- Decreased efficiency: If the equipment isn’t operating at optimal levels, it may be due to faulty components.

- Unusual noises or vibrations: Any irregular sounds or shaking during operation could signal a need for part replacement.